System and Methods for Organic Material Conversion and Energy Generation

a technology of organic material and conversion method, applied in the direction of energy input, combustion type, lighting and heating apparatus, etc., can solve the problems of insufficient mixing of material, inability to independently control the speed and amount of mixing with time, and the production of reaction water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

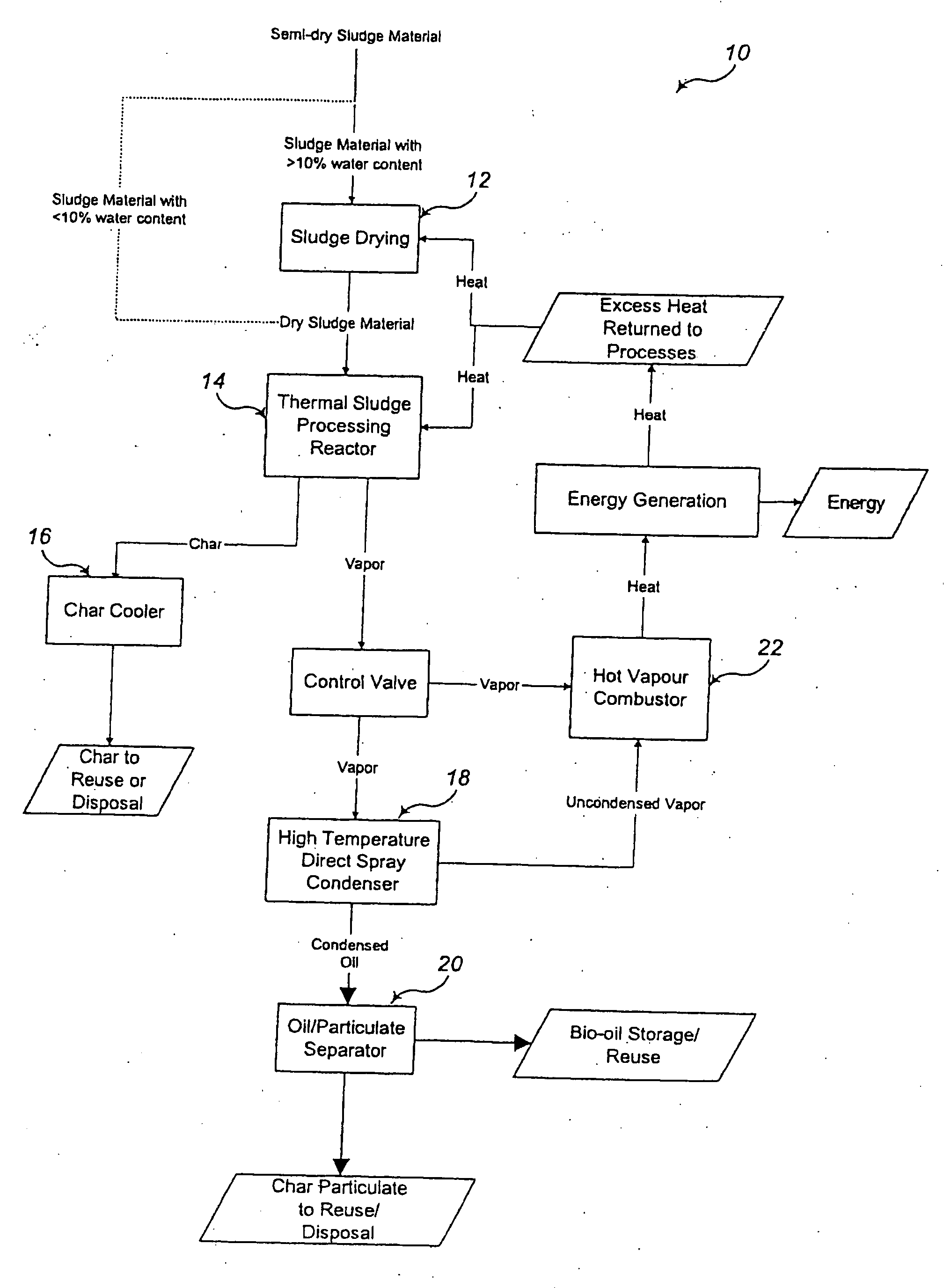

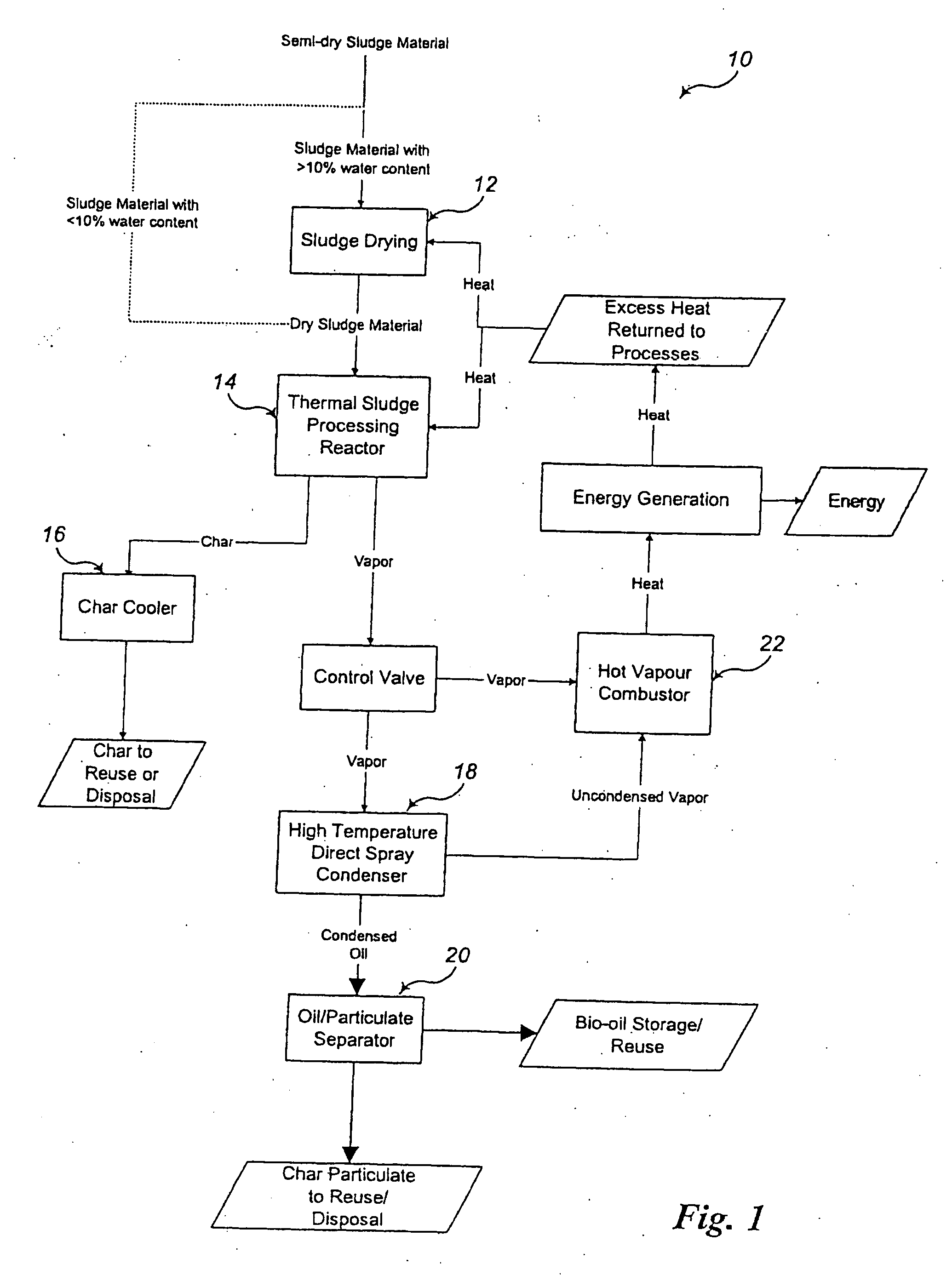

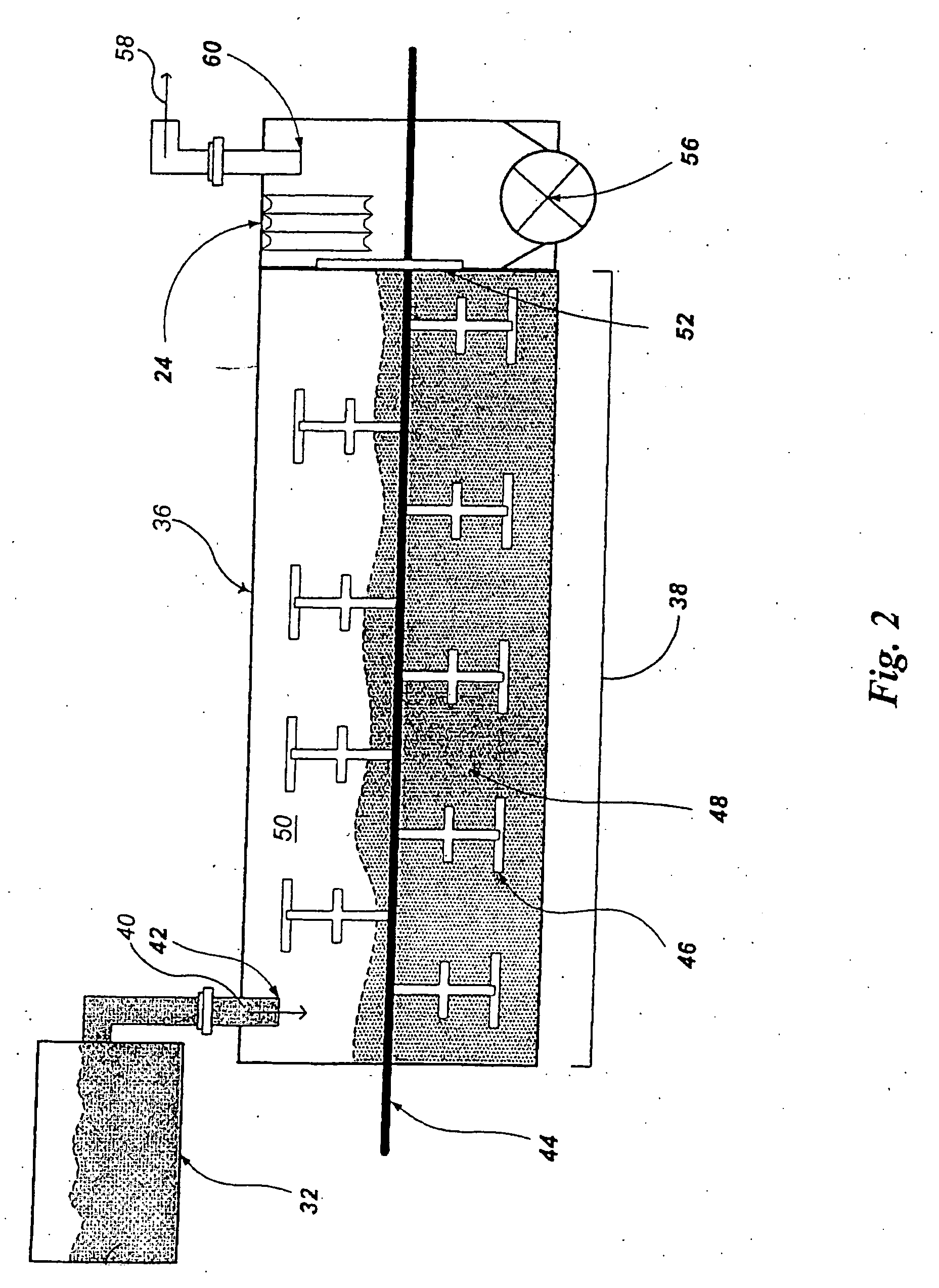

[0052] Industrial and municipal wastewater treatment plants produce significant amounts of sludge that must be properly treated for disposal. Thermal conversion processes such as pyrolysis can be used to convert sludge into bio-oil and char that can have a wide variety of commercial and industrial applications. However, prior approaches to these processes have suffered from many drawbacks. Some of these drawbacks include the creation of reaction water and the inability to independently control the mixing of sludge material within a reaction chamber and the time the sludge spends within the reaction chamber. This particular drawback requires that operation be conducted in batches whereby a batch of sludge material is fully processed before the quality of the resulting oil can be tested. This batch process is time consuming and, when adjustments are needed, requires that the entire pyrolysis process be shut down while manually actuated valves, screws, and other moving parts are adjust...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com