Infrared radiation element and gas sensor using it

a gas sensor and infrared radiation technology, applied in the direction of thermoelectric devices, optical radiation measurement, instruments, etc., can solve problems such as heat generator breakag

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

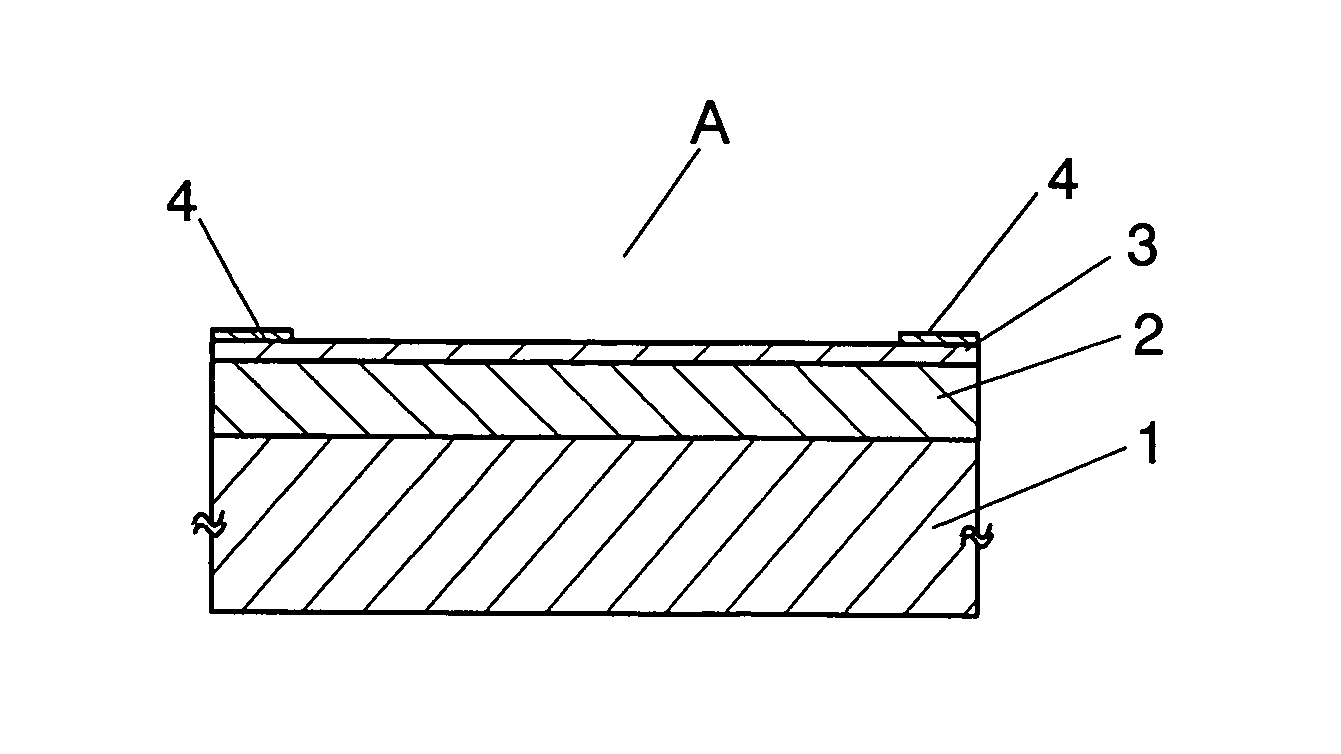

[0029] Hereinafter, an infrared radiation element (A) of the present invention will be described in more detail with reference to the accompanying drawings.

[0030] The infrared radiation element (A) of the present invention is an infrared radiation element which emits infrared rays from a heating layer 3 by heating a heating layer 3 by energization of the heating layer 3. In the infrared radiation element (A), a heat insulating layer 2, which is porous and has sufficiently smaller thermal conductivity than a semiconductor substrate 1, is formed on a surface in the thickness direction of the semiconductor substrate 1 (namely, on an upper surface of FIG. 1), and the heating layer 3, which is in the form of a lamina (a plane) and has larger thermal conductivity and larger electrical conductivity than the heat insulating layer 2, is formed on the heat insulating layer 2, and a pair of pads (electrodes) 4 for energization are formed on the heating layer 3. The semiconductor substrate 1 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com