High stability and high capacity precursor vapor generation for thin film deposition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

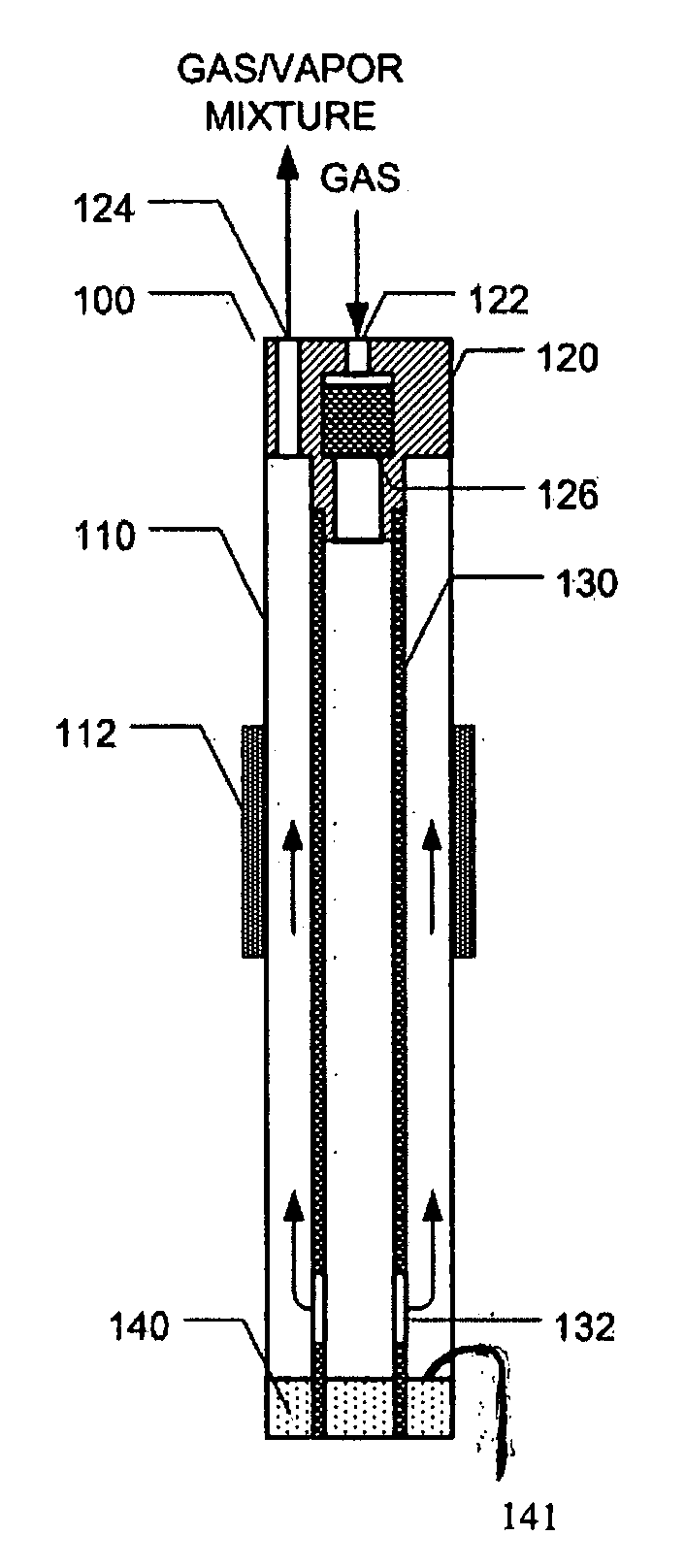

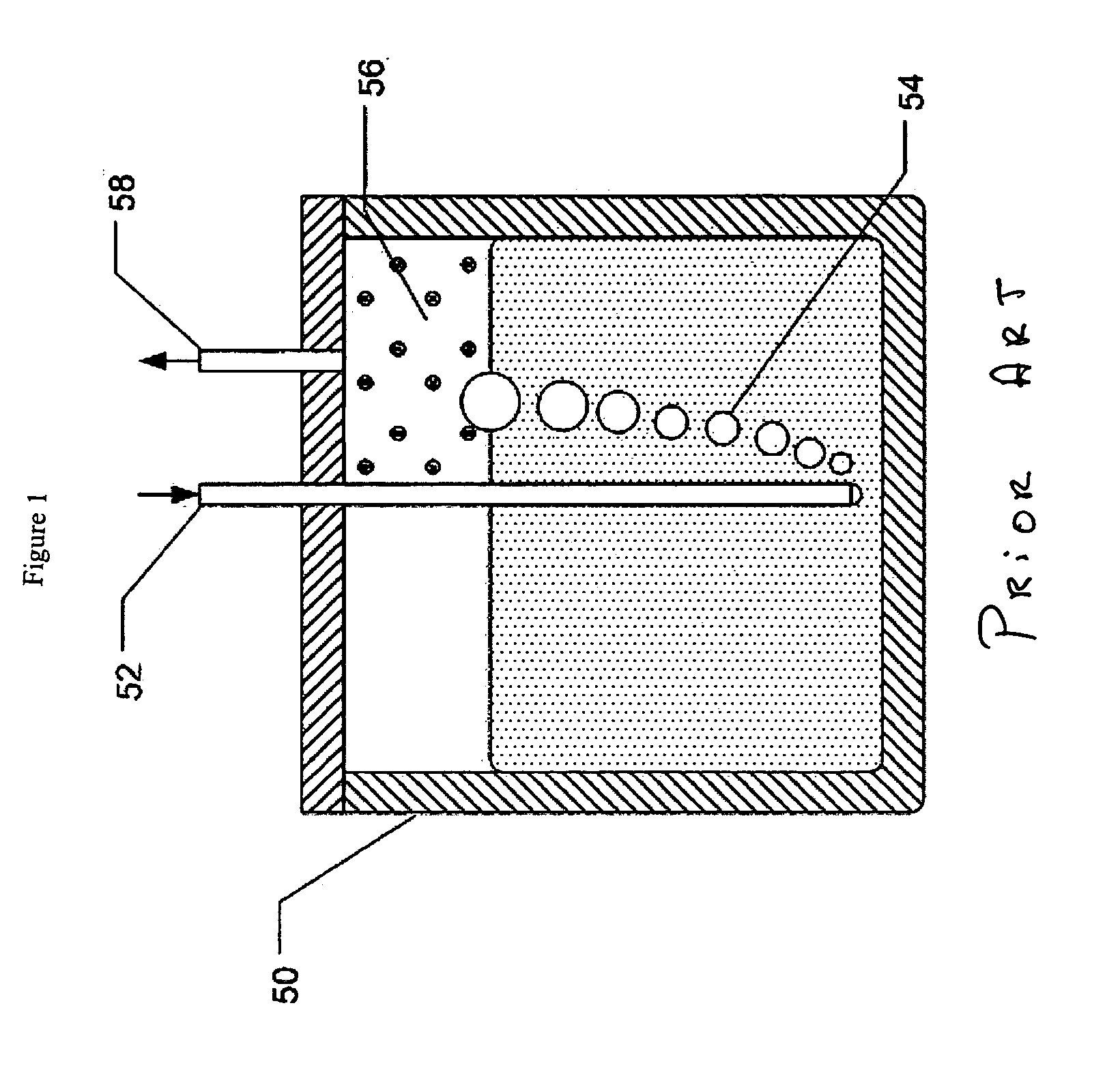

[0024] This invention includes a new approach to liquid vaporization for gas saturation that would overcome the disadvantages of the prior art bubbler of FIG. 1. A small amount of liquid is placed in the vaporizer to minimize thermal decomposition. The new vaporization apparatus is also highly stable and repeatable and capable of generating high purity gas / vapor mixtures that are substantially free of particulate contaminants. The resulting high purity gas / vapor mixture is suitable for use in semiconductor and other industries for film deposition on a substrate for semiconductor device fabrication or other applications

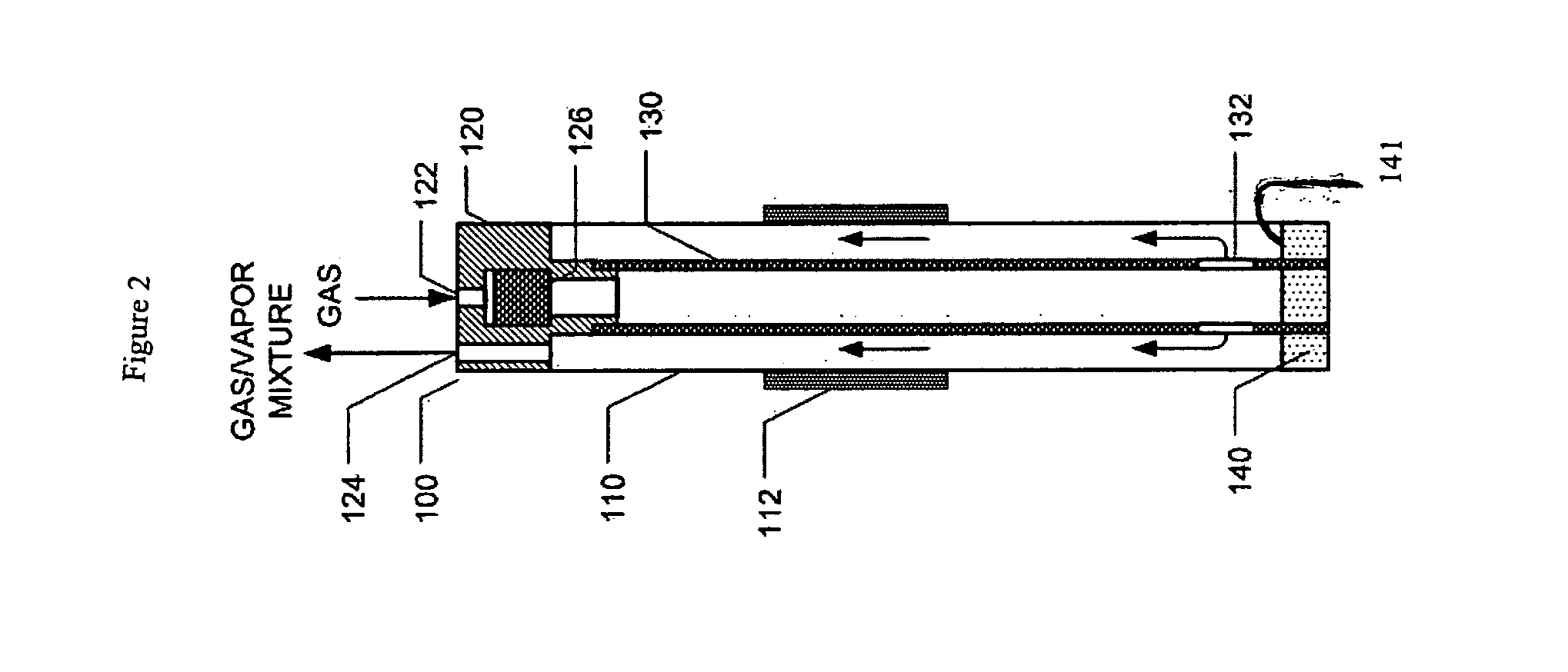

[0025] A vaporization apparatus described in this invention is generally indicated at 100 in FIG. 2. Like reference characters will be used to indicate like elements throughout the drawings. The vaporization apparatus 100 will also be referred to as a diffusion vaporizer. Although gas saturation occurs by vapor diffusion both in the present apparatus as well as the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com