System and method for preventing blow-by of liquefied gases

a technology of liquefied gas and system, applied in the field of process control, can solve the problems of large, dangerous cloud of boiling white ln2 “smoke” and “blow-by” of liquefied gas, and achieve the effect of preventing the blow-by of ln2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

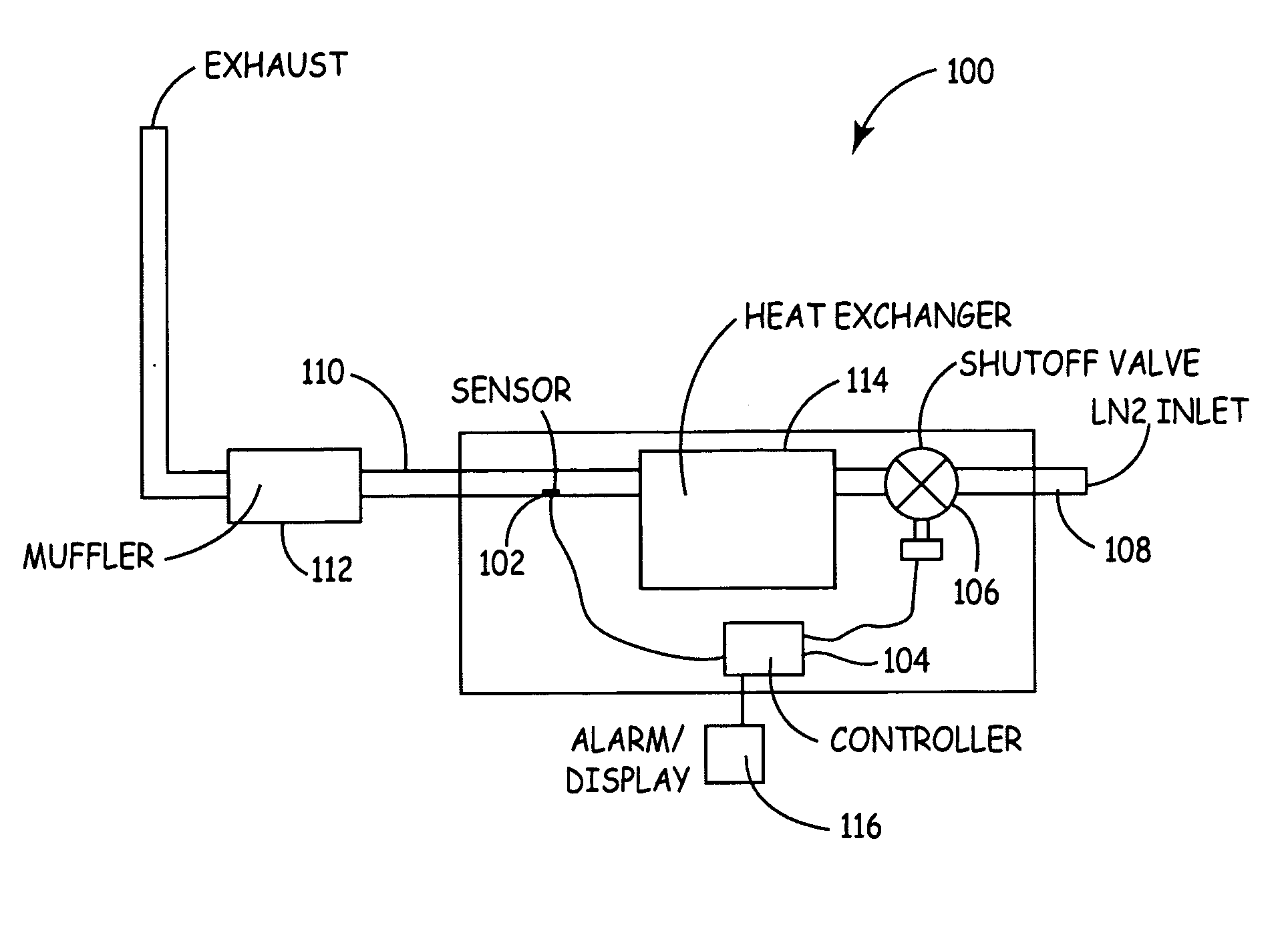

[0009] With reference now to the figures, FIG. 1 depicts a pictorial representation of an example system 100 for preventing blow-by of a liquefied gas, which can be used to implement a preferred embodiment of the present invention. For this illustrative embodiment, LN2 is used as a coolant in an example heat transfer application. As such, system 100 includes a temperature sensor 102 connected to an input of a controller unit 104. For example, controller unit 104 can be implemented with a suitable digital or analog process controller, microcontroller, digital processor, etc. An output of controller unit 104 is connected to an input of a shutoff valve 106. The shutoff valve 106 is located in series between an inlet tube 108 and a heat exchanger 114, and the temperature sensor 102 is coupled to an exhaust tube 110 of the heat exchanger 114, so that temperature sensor 102 can sense the temperature of the exhaust tube 110 at that location. As an option, the controller unit 104 is also co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com