Optical waveguide, optical waveguide module and method for forming optical waveguide

a technology of optical waveguides and modules, applied in the field of optical waveguides, can solve problems such as interior arrangement and landscape spoilage, and achieve the effect of reducing connection loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

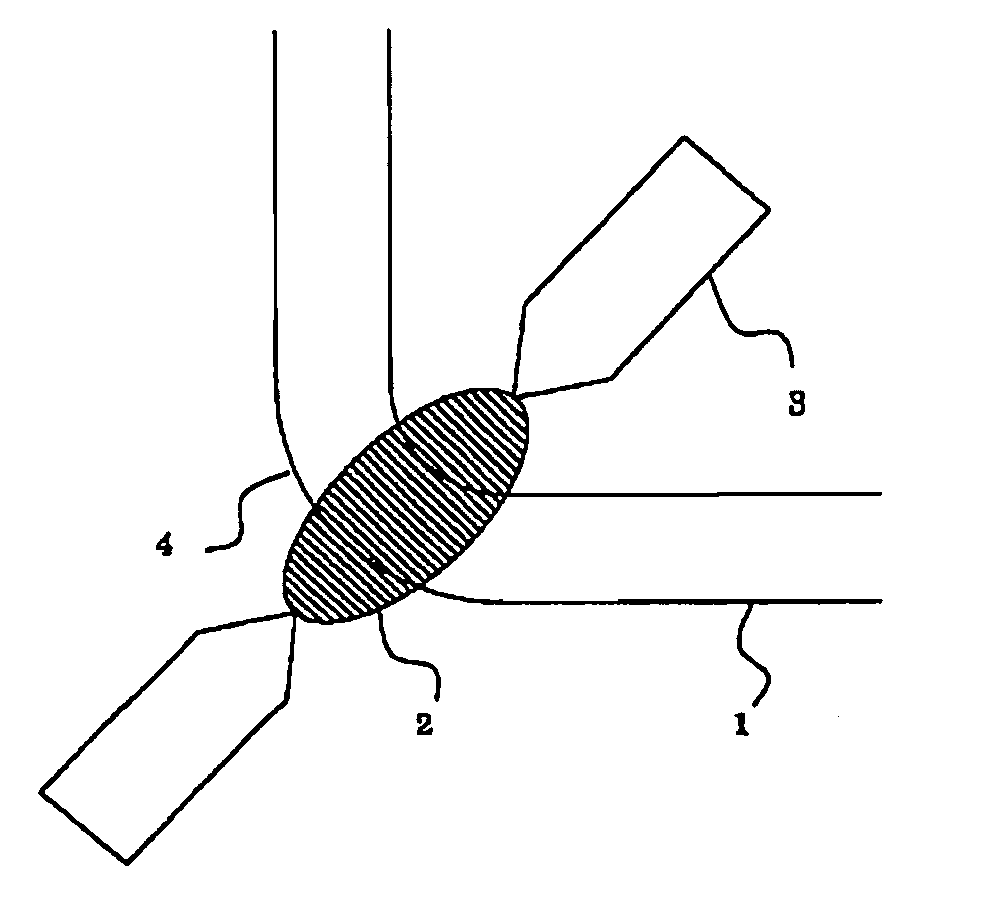

[0060]FIG. 1 is a schematic diagram showing a first mode of an optical waveguide related to the present invention. The specified portion of the optical waveguide is heated by arc discharge to high temperature (more than holding point, less than softening point) and the optical waveguide is bent at a prescribed radius). Since this optical waveguide becomes in a thermoneutral environment after the bent portion of the optical waveguide is bent at high temperature, there is no distortion due to bent. That means it is processed in such that an initial state is a bend state. When the optical waveguide is deformed after processed state, distortion occurs to cause breakage. When the optical waveguide is bent before the process, distortion does not occur to prevent breakage.

[0061] However, when this bent portion is restored to linear state, distortion occurs to cause breakage. Selection whether an initial distortion free state is a linear state or a bent state ends up preventing breakage wh...

second embodiment

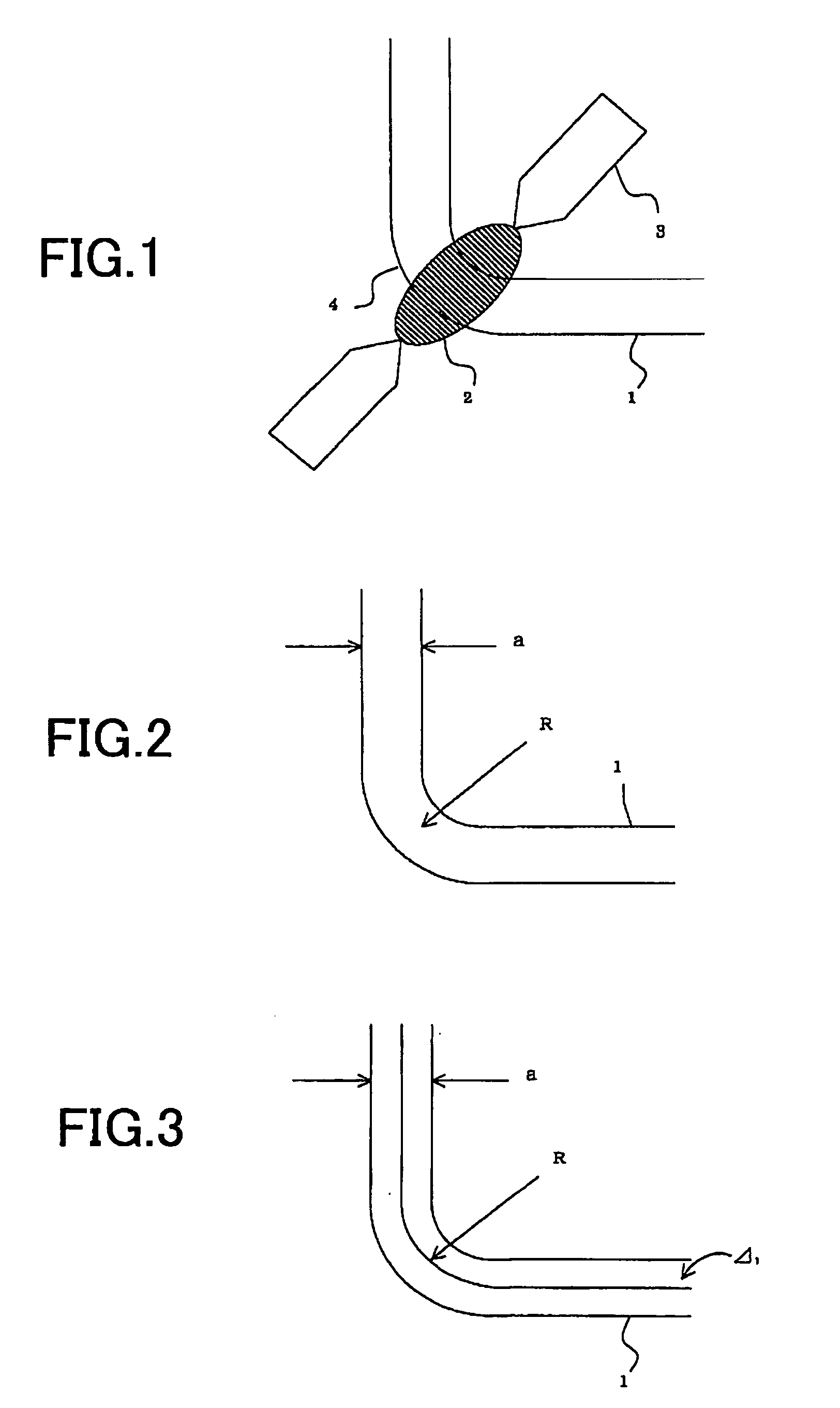

[0063]FIG. 2 is a schematic diagram showing third and fifth modes of an optical waveguide related to the present invention. In these modes where an optical waveguide direction is converted at a minute space, actually usable size is specified based on physical size of the used optical waveguide. In these modes, an external diameter a of the optical waveguide is not less than 50 μm, and a bend radius R is not more than 5.0 mm. That means, it is not physically possible that an optical waveguide with an external diameter a of 50 μm is bent at a bend radius R of 50 μm. It is neither easy to handle an optical waveguide with an external diameter a of less than 50 μm. Therefore, the minimum external diameter a of an optical waveguide is specified 50 μm to secure easy handling and the bend radius of used optical waveguide is specified 10 times of the minimum external diameter to physically realize the bend.

[0064] Further, since 125 μm of external diameter is convertible diameter with the ty...

third embodiment

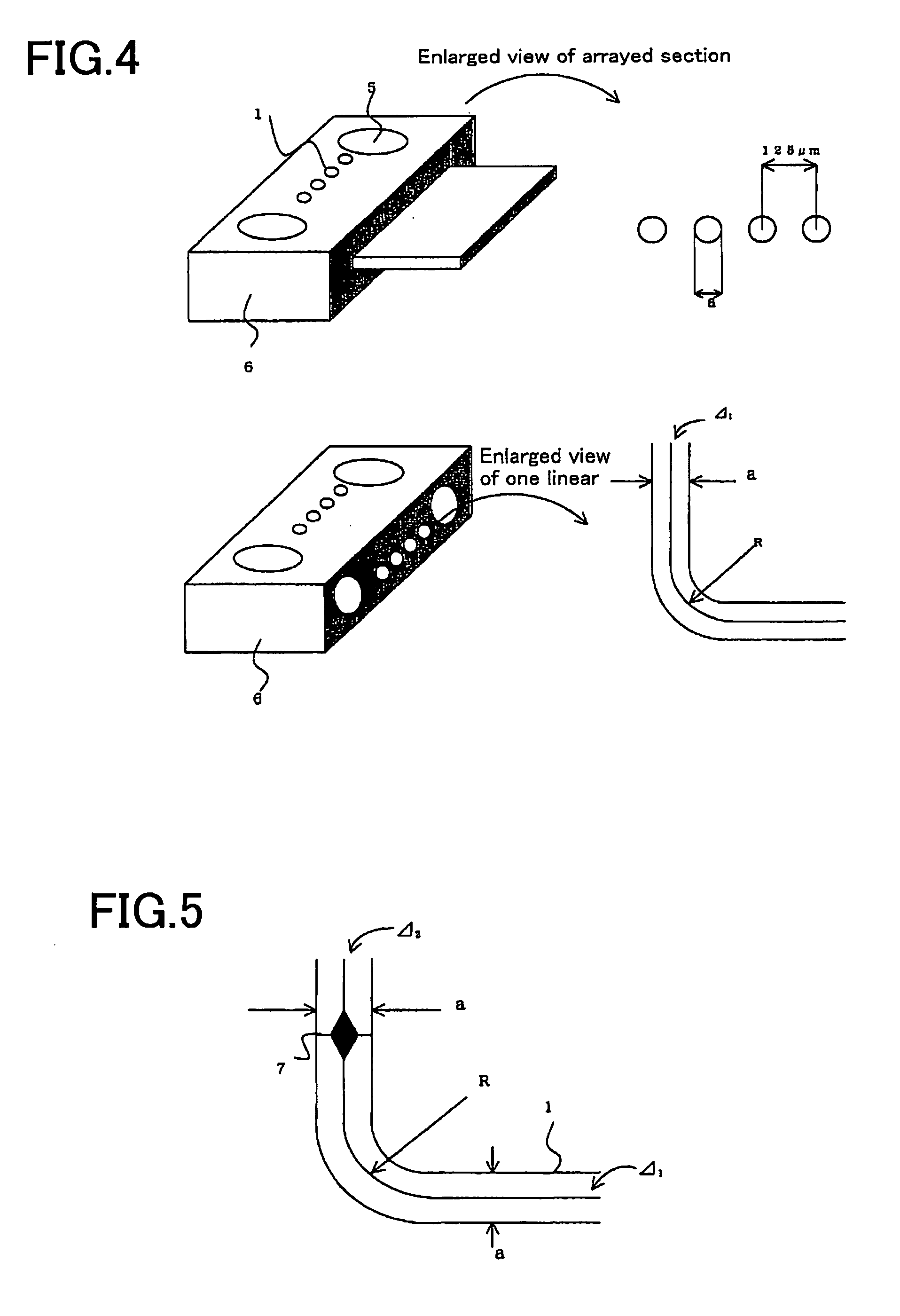

[0066]FIG. 3 is a schematic diagram showing sixth mode of optical waveguide related to the present invention. A method for preventing mechanical breakage is focused in the optical waveguide direction in the minute space according to the second embodiment. However in this embodiment the optical waveguide direction can be converted in the minute space while maintaining optical characteristics in good condition. An equivalent refractive index difference Δ1 between core and clad of the optical waveguide is within a range from not less than 0.8% to not more than 3.5%, preferably within a range from not less than 1.0% to not more than 3.0%. In the generally used optical waveguide, an general difference Δ1 between the core and the clad is around 0.3%. However, when the optical waveguide having an equivalent refractive index difference Δ1 of about 0.3% is bent at bend radius R of not more than 5.0 mm, light confined in the core is not confined any more and is radiated to the clad, thereby d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com