Oil pump

a technology of oil pumps and oil pumps, applied in the direction of machines/engines, liquid fuel engines, semiconductor/solid-state device details, etc., can solve the problems of increasing the dimension of the pump, and affecting the performance of the oil pump. achieve the effect of high performance of the oil pump

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

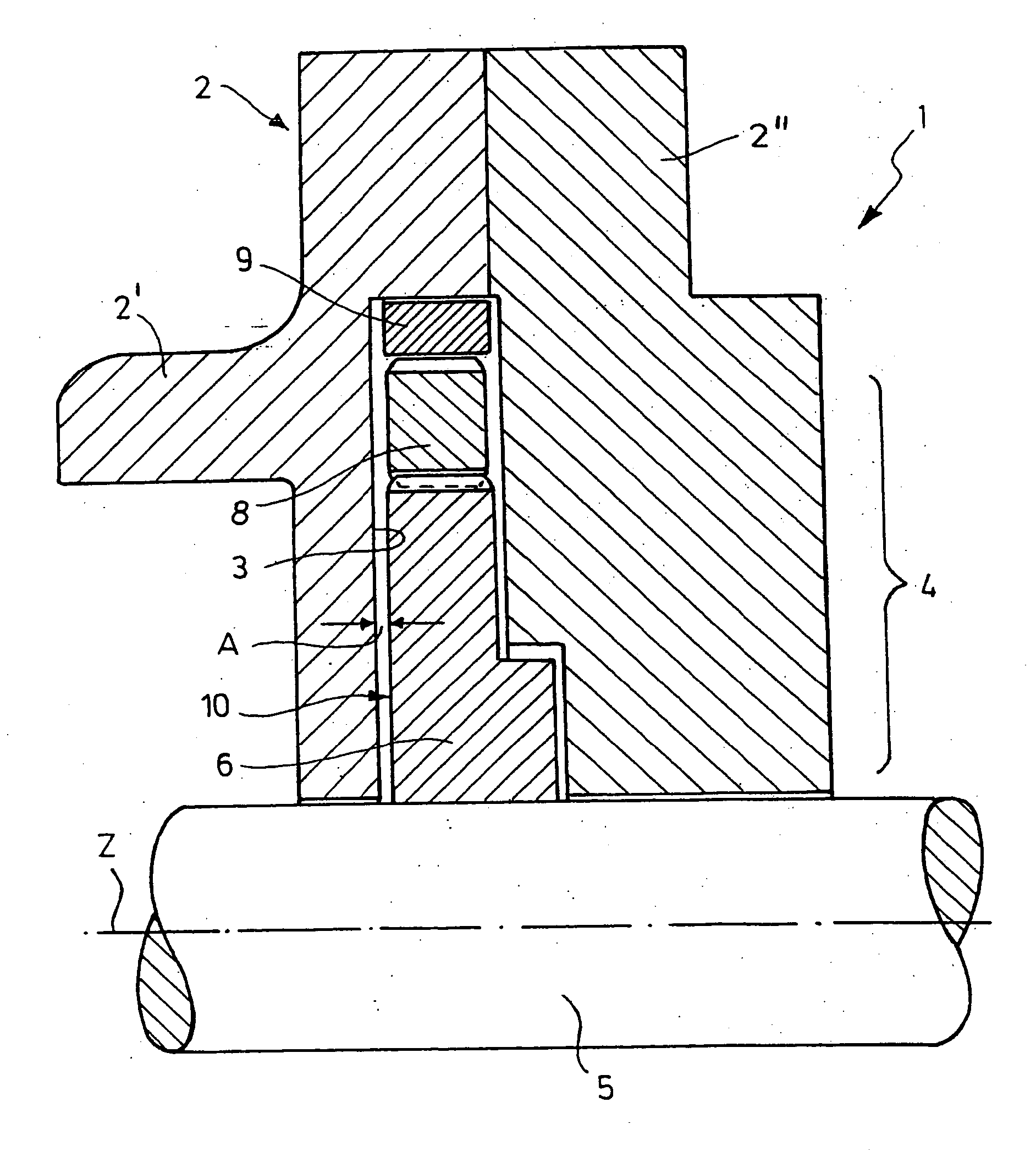

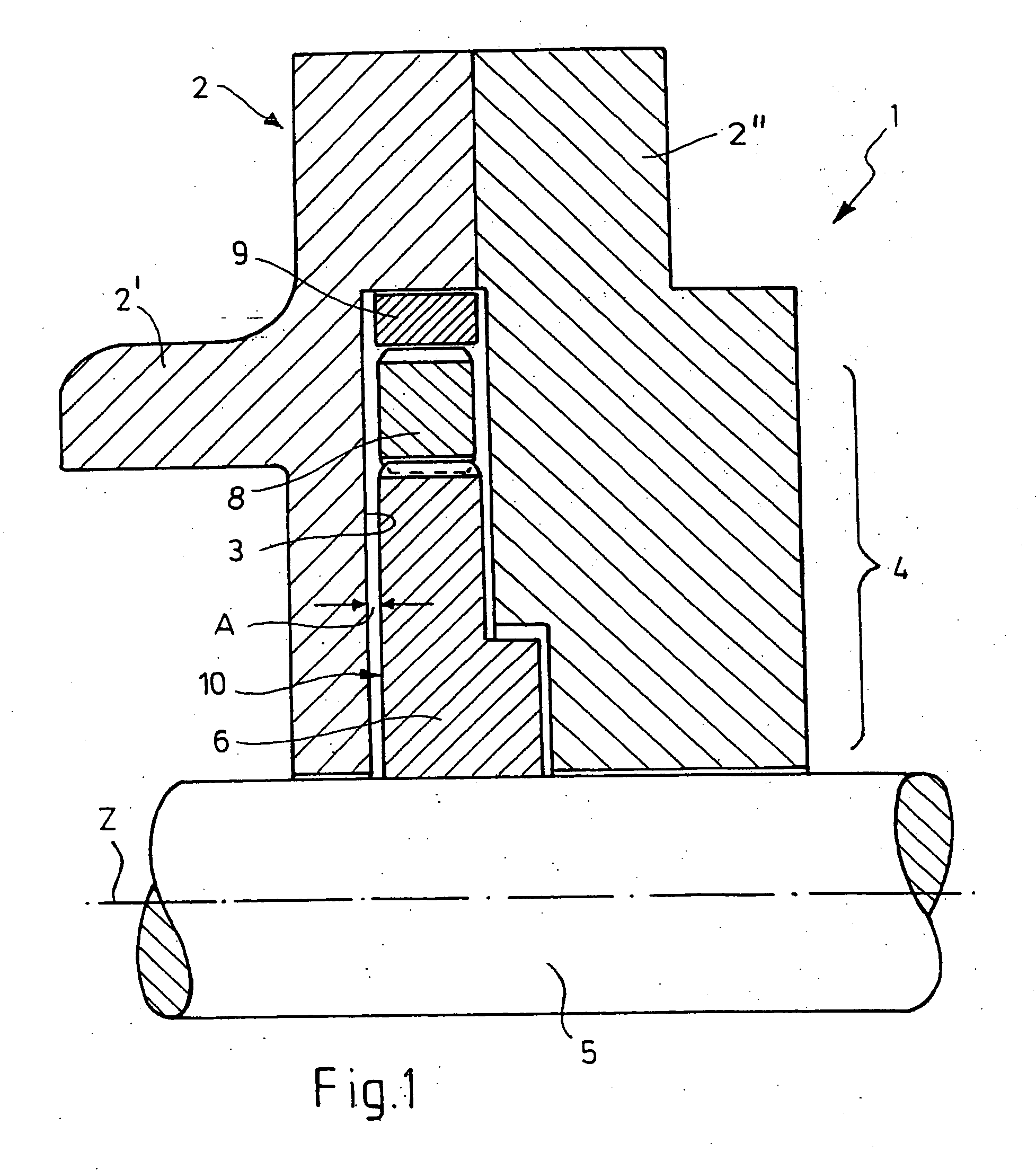

[0023]FIG. 1 shows an oil pump of the type P-rotor according to the invention, in its entirety indicated with the reference number 1, (as it is disclosed in DE 196 46 359 C2, for example, having a housing 2, which is embodied in two parts (2′, 2″) here. In this housing 2, a set of toothed rotors 4 is arranged, having an interior rotor 6 arranged on a shaft 5 in the direction of the axis Z, and the planet wheels 8 encircling it. It will be appreciated by one skilled in the art that the description given herein with respect to those FIG. 1 is for exemplary purposes only and is not intended in any way to limit the scope of the present invention.

[0024] Furthermore, the set of toothed rotors 4 comprises a rotating circular bearing 9 with bearing pockets, not shown here, in which the pivotally supported planet wheels 8 are arranged. The interior rotor 6 is supported eccentrically in reference to the circular bearing 9, and is provided with an approximately star-shaped exterior contour, w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com