Gallium nitride material devices and methods of forming the same

a gallium nitride and silicon substrate technology, applied in the field of silicon substrate can solve the problems of presenting challenges in the process of forming gallium nitride materials on silicon substrates to produce semiconductor devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The invention provides gallium nitride material structures, devices and methods of forming the structures and devices.

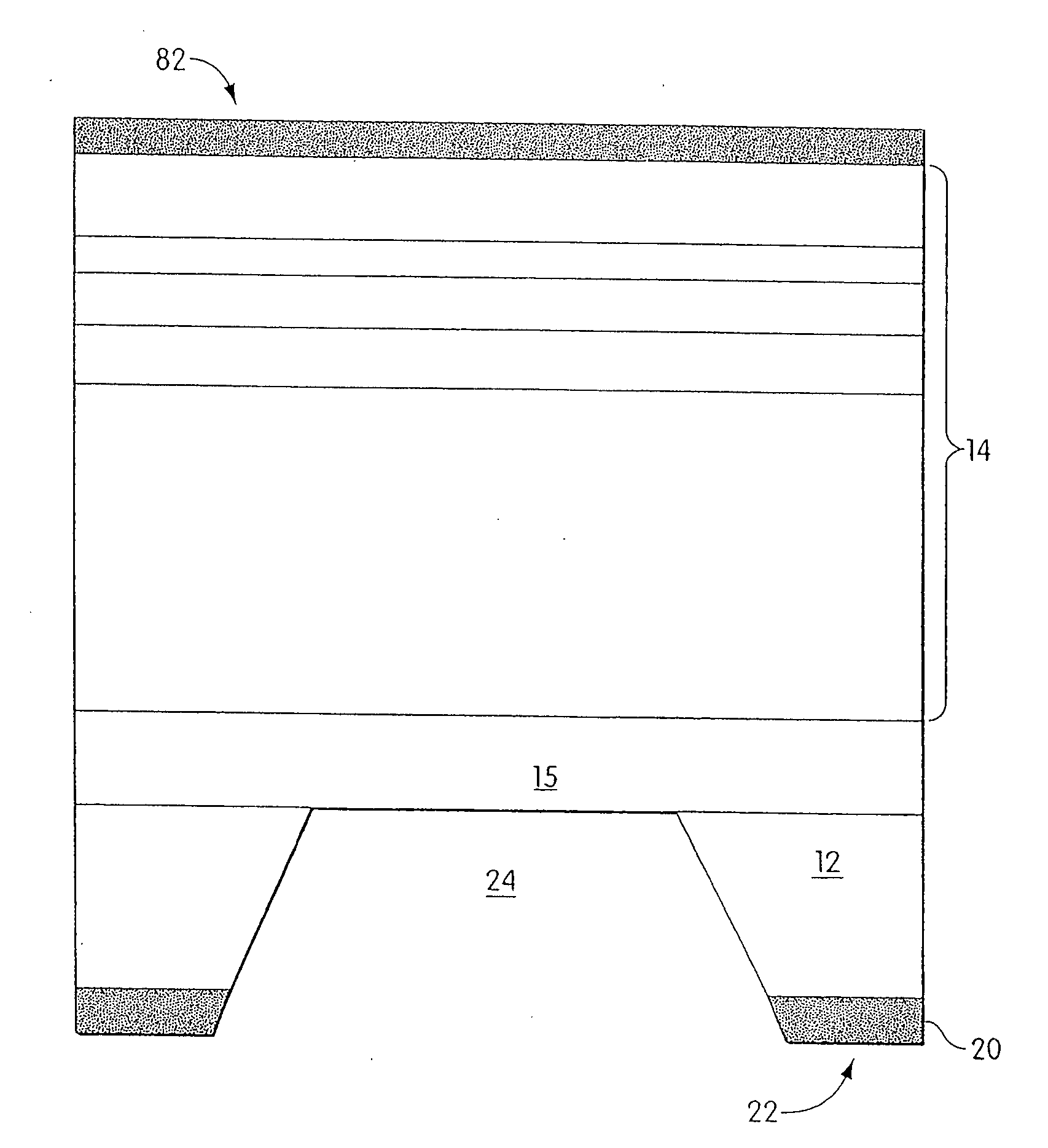

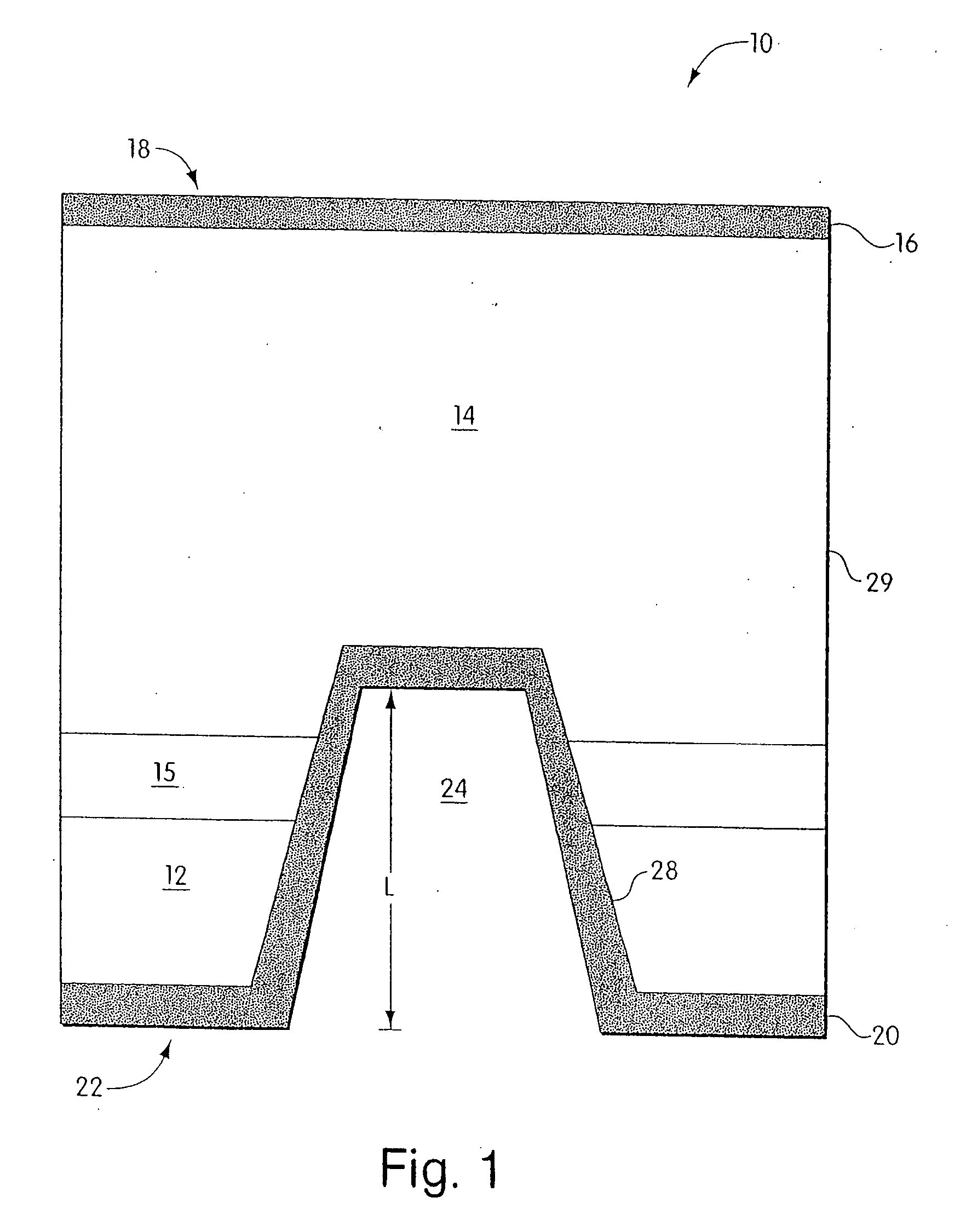

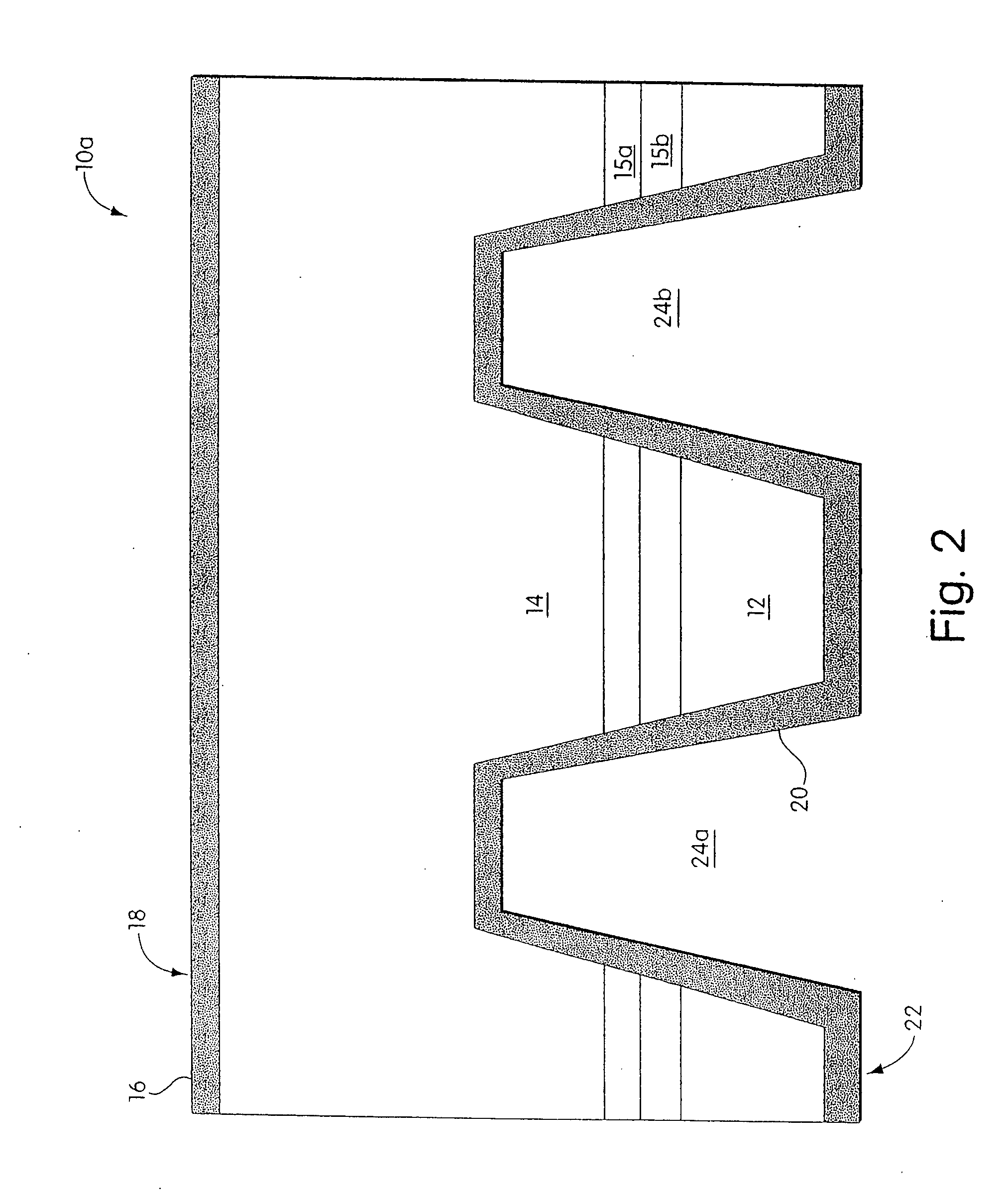

[0047] Referring to FIG. 1, a semiconductor device 10 according to one embodiment of the invention is shown. Semiconductor device 10 includes a substrate 12 and a gallium nitride material device region 14 formed over the substrate. As described further below, device structures are typically formed, at least in part, within gallium nitride material region 14. Device 10 further includes a transition layer 15 formed on substrate 12, for example, to facilitate the subsequent deposition of gallium nitride material device region 14. In some cases, the transition layer (or, at least a portion of the transition layer) may be non-conducting. A topside electrical contact 16 (on a topside 18 of the device) and a backside electrical contact 20 (on a backside 22 of the device) are provided for connection to an external power supply that powers the device. Backside contact...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

| diameters | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com