Thin film transistor array substrate and manufacturing method thereof

a technology of thin film transistors and array substrates, which is applied in the direction of instruments, semiconductor devices, electrical apparatuses, etc., can solve the problems of panel scrapping, difficult to control a good taper angle,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

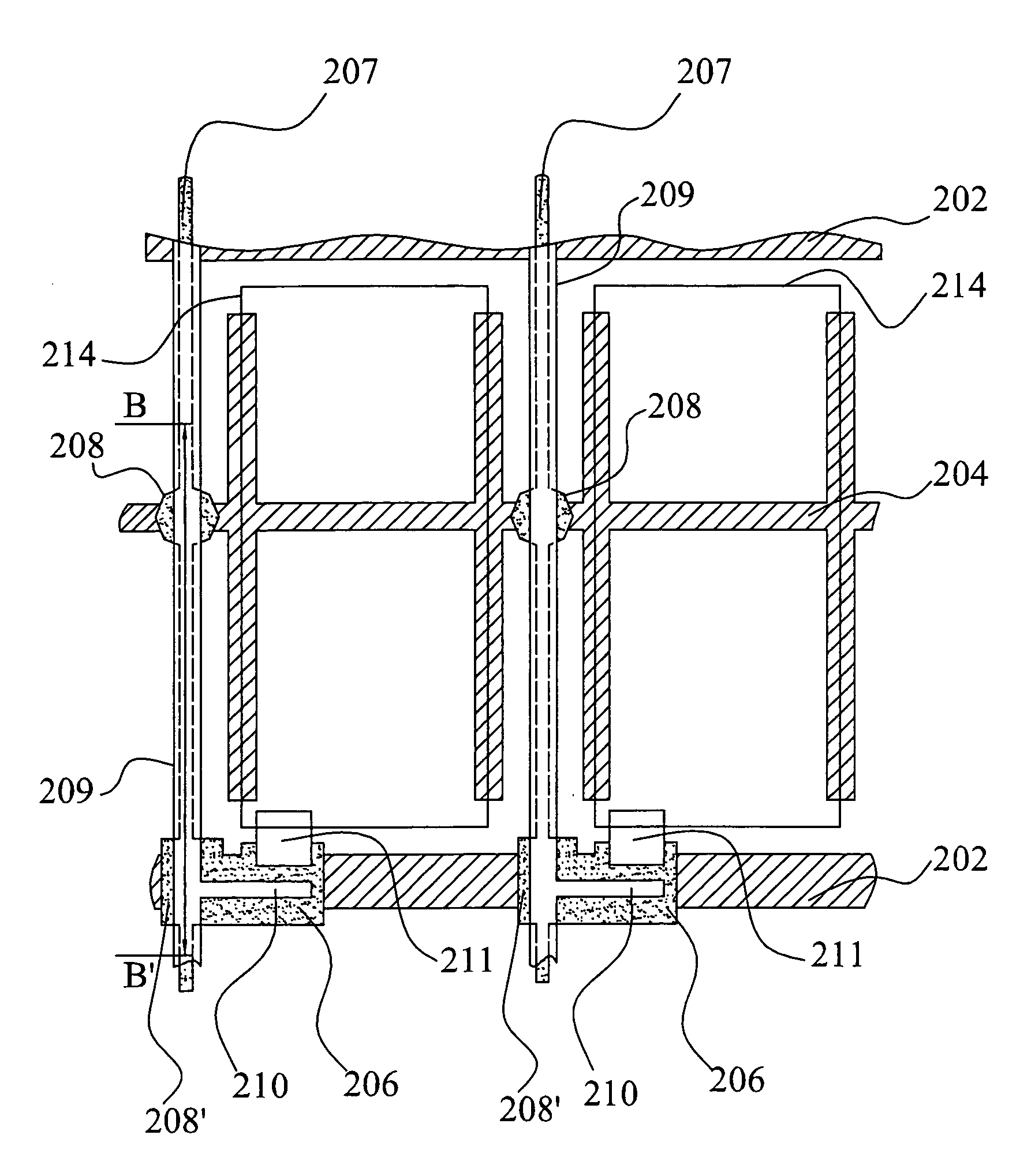

[0018]FIG. 3 is a plan view of the thin film transistor array substrate illustrated one embodiment of the present invention. Such as shown in FIG. 3, in the present embodiment, a thin film transistor (TFT) array substrate includes a plurality of scan lines 202 and a plurality of source lines 209 disposed on the substrate and define a plurality of pixel regions. A plurality of storage capacitance lines (Cs line) 204 are disposed on the substrate in a direction extending along to across the pixel regions, and each of Cs lines 204 is essentially perpendicular to each of the source lines 209 to form a cross portion. A plurality of patterned thin films 208 are disposed on Cs lines 204 and above the cross portion.

[0019]Following the foregoing, in the present embodiment, the scan lines 202 and the Cs lines 204 are simultaneously formed in the same process. After, an insulating layer (not shown FIG. 3) is disposed to cover the scan lines 202 and the Cs lines 204. Wherein, the patterned thin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com