Low- friction sliding mechanism and uses thereof

a sliding mechanism and low friction technology, applied in mechanical devices, hoisting equipment, machines/engines, etc., can solve the problem that no research has been made on the material combination of ionic liquid and sliding members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

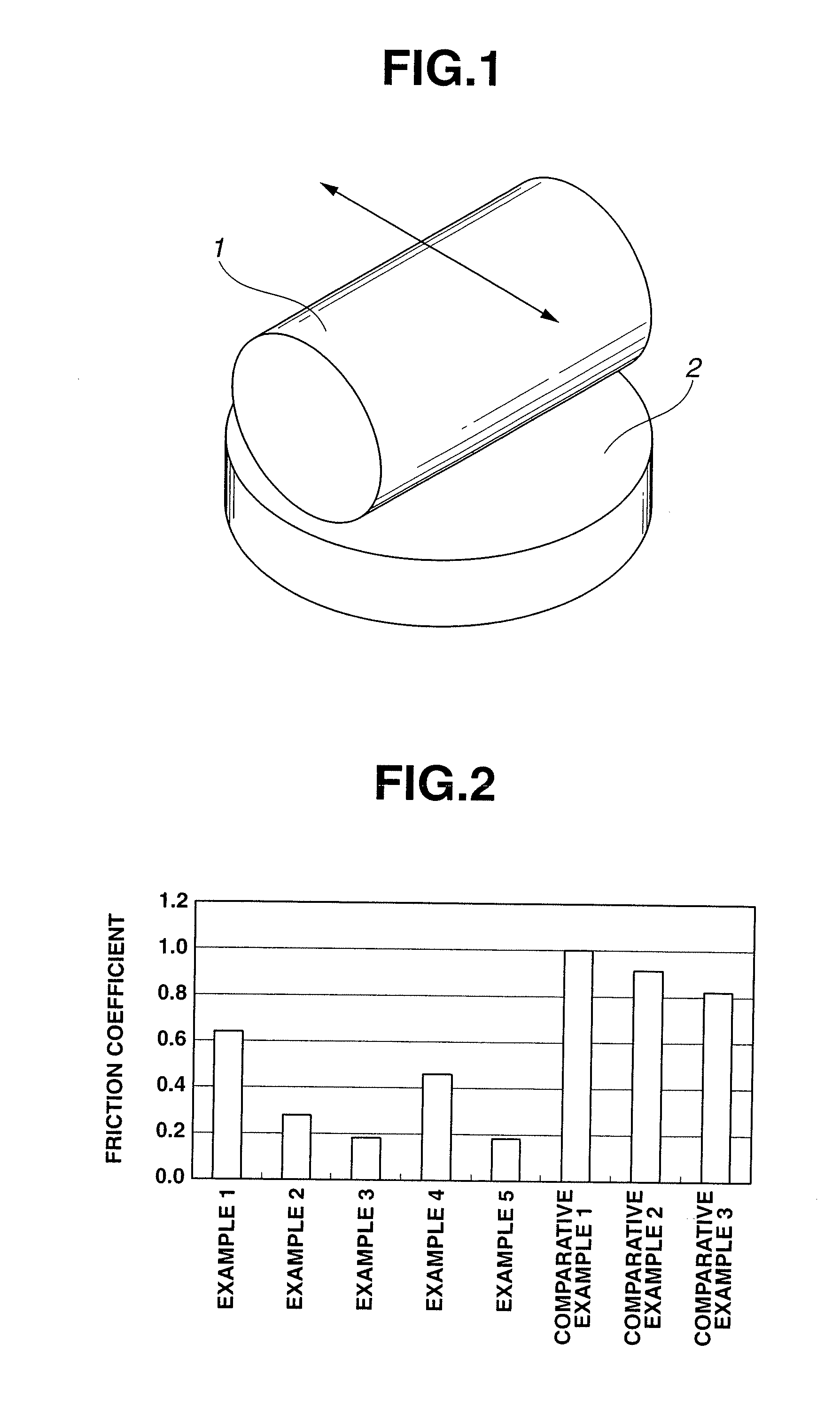

Examples

Embodiment Construction

[0013]The present invention will be described below in detail. In the following description, all percentages (%) are by mass unless otherwise specified.

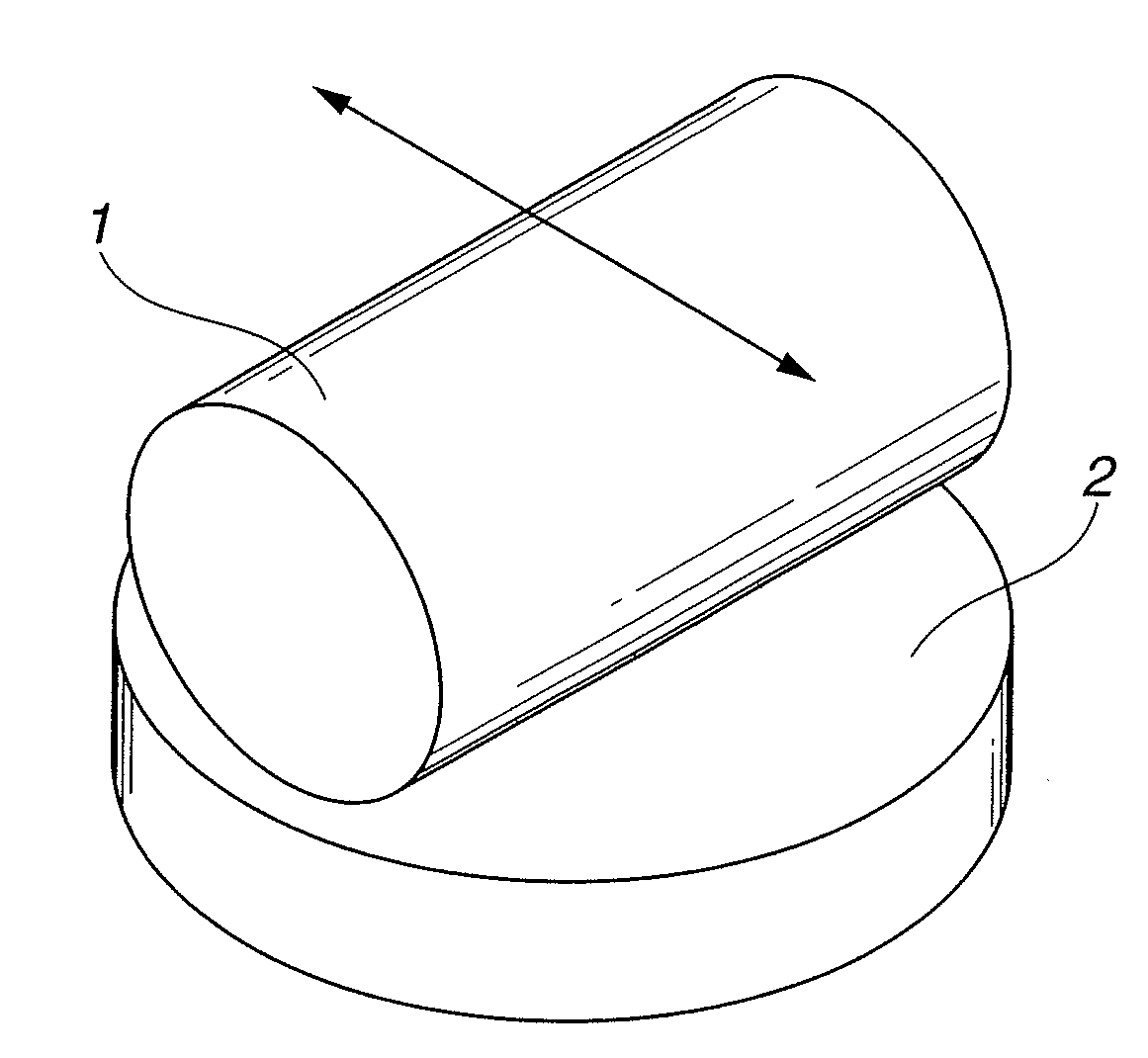

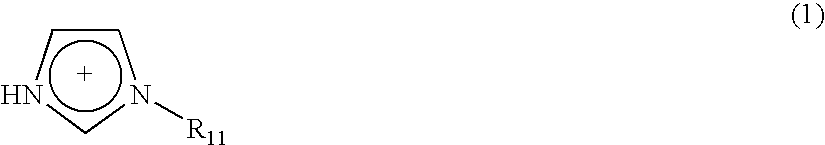

[0014]A low-friction sliding mechanism according to one exemplary embodiment of the present invention includes a pair of sliding members having sliding surfaces slidable relative to each other and a lubricant applied to the respective sliding surfaces, characterized in that: at least one of the sliding surfaces has a thin coating of either a diamond-like carbon (DLC) material, a diamond material or a combination thereof, and the lubricant is either an ionic liquid consisting of cation and anion components and existing in liquid or gel form at room temperature or an ionic conductive composition thereof.

[0015]Preferably, the DLC material and the diamond material have a sp3 / sp2 carbon ratio of 2 or greater. If the sp3 / sp2 carbon ratio is smaller than 2, the DLC material and the diamond material are too low in hardness to obtain a suffic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystal grain size | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| crystal grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com