Gravel bag and method for protecting and exit point for stormwater

a stormwater and gravel bag technology, applied in the field of construction sites, can solve the problems of multiple crushing impacts, increased runoff volume, environmental damage, ecosystem disturbance, etc., and achieve the effects of low cost, high tensile strength, and effective padding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

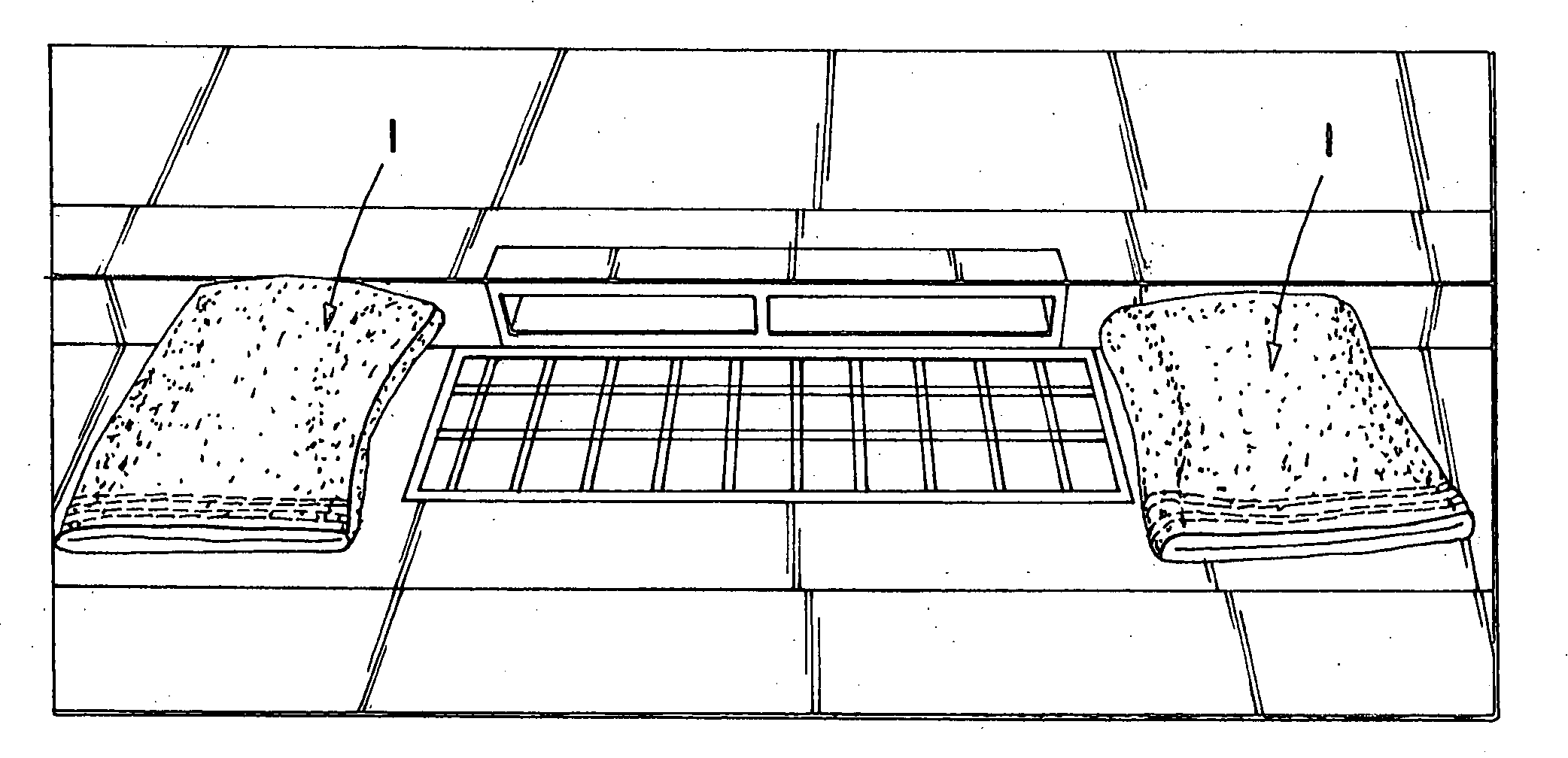

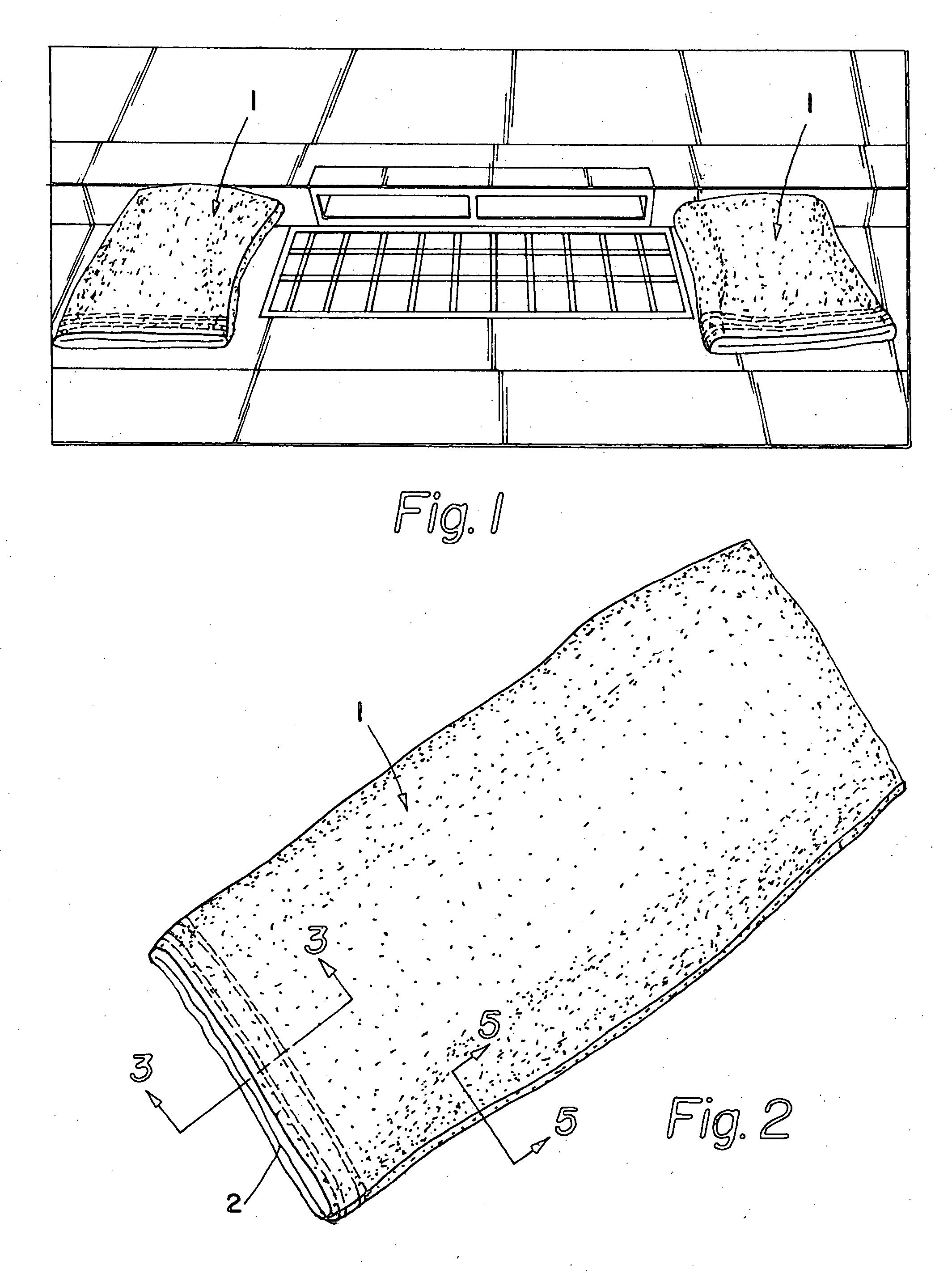

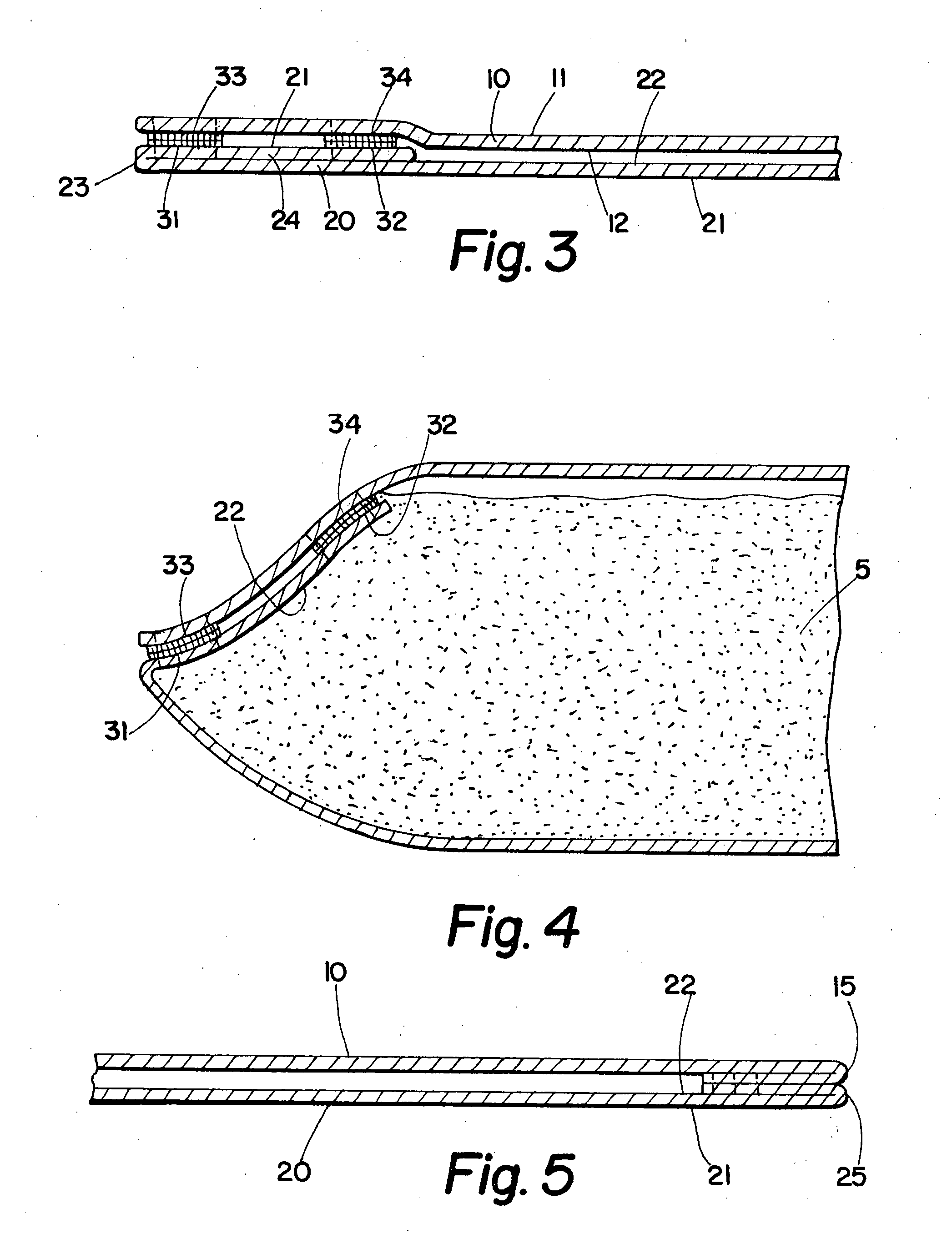

[0031]The present invention is an improved gravel bag 1 (see FIG. 1) manufactured from a single layer of a heavy-duty geotextile composite material (also referred to as “geo-composite”) comprising a closure device resistant to opening as pressure is applied from within. For purposes of this patent application, the term composite material shall refer to a material made from two or more constituent materials with at least two substantially different mechanical properties, substantially and tightly affixed to one another across a majority of their sheet like structure, and which remain separate and distinct within the finished structure.

[0032]Referring now to FIG. 3, in a preferred embodiment of the invention, the first material is a nonwoven material 40 created through the compression of loose threads. See FIG. 6. This material is felt-like in feel and appearance, and comprises flexible yet strong materials such as polypropylene or polyester (2 to 15-oz per sq-yd, preferably 6-oz per ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com