Single-pass recording of multilevel patterned media

a multi-level patterned, single-pass technology, applied in the direction of data recording, instruments, coating parts of supports with magnetic layers, etc., can solve the problems of noise generation during reading, errors in reading, reading process, etc., to improve the multi-level patterned magnetic recording medium and improve the magnetic data/information recording and retrieval system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

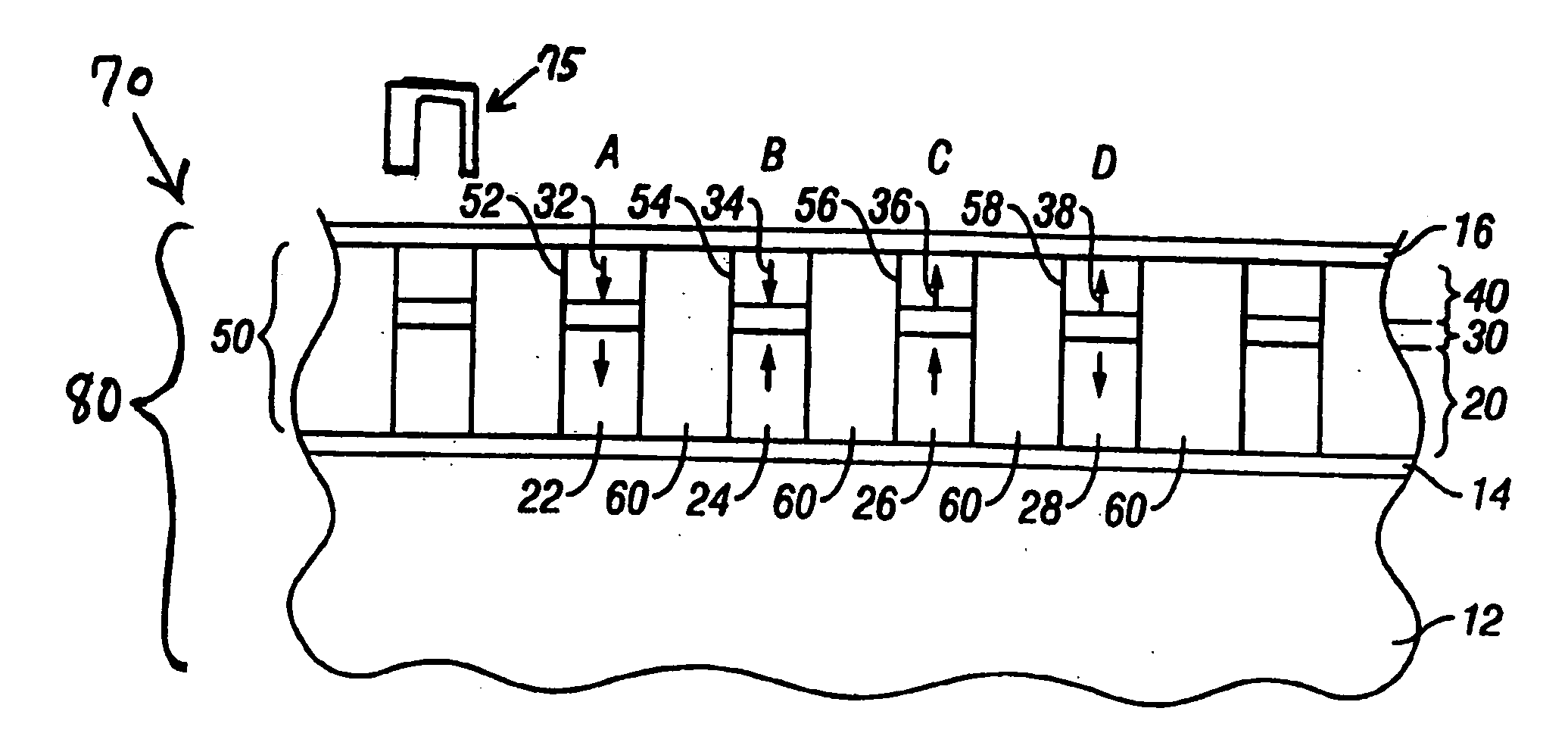

[0052]The present invention addresses and remediates the aforementioned drawbacks and disadvantages associated with conventionally structured patterned multilevel magnetic recording media, wherein each level is required to be addressed individually, thereby necessitating multiple passes of the write head over the media for writing data to each level and incurring a substantial decrease in data write rate, while maintaining full compatibility with all aspects of conventional manufacturing technology and methodology for patterned magnetic media.

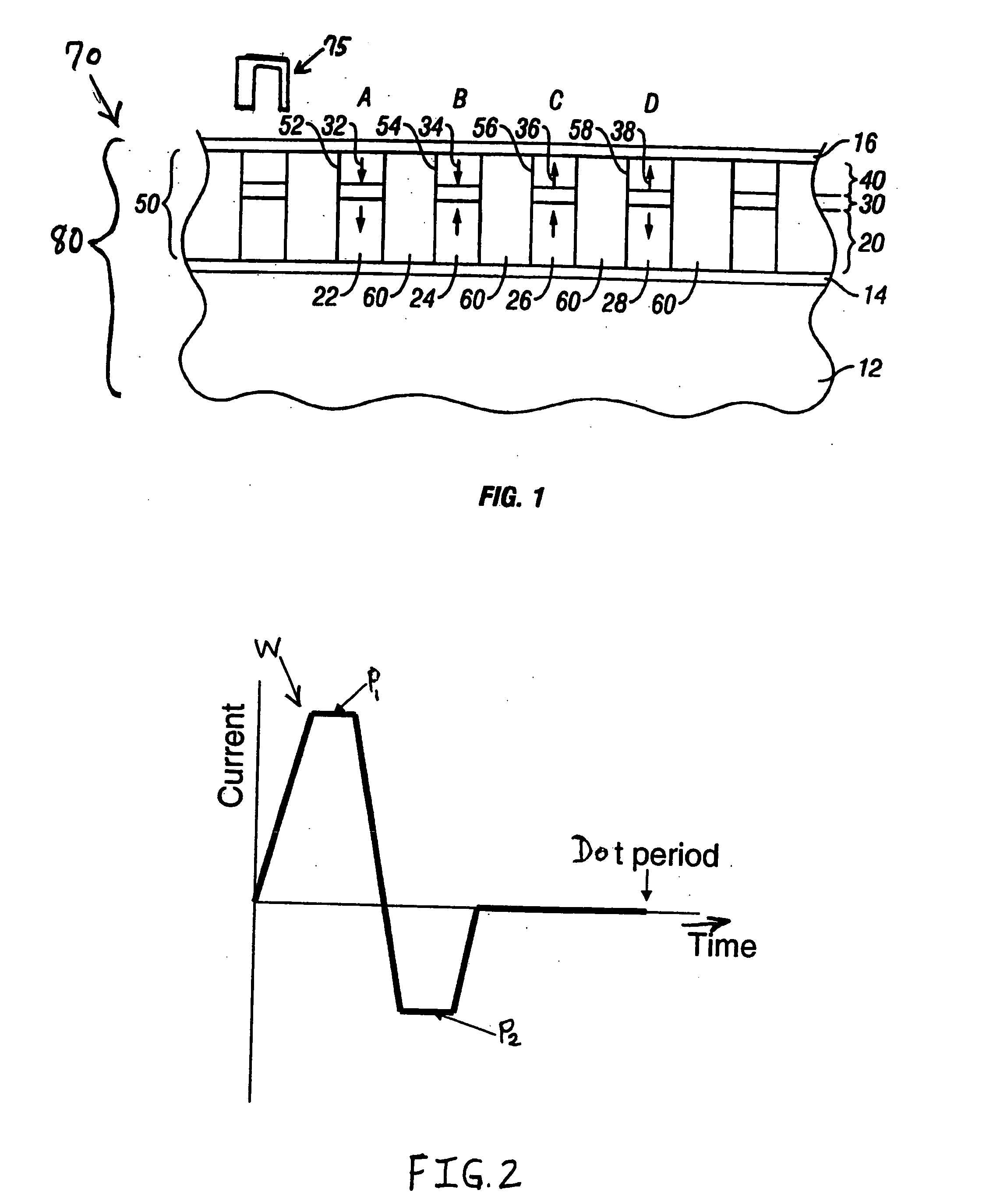

[0053]Briefly stated, the present inventors have determined that improved methodology for writing to multilevel patterned magnetic media with n levels is provided by a method wherein writing to the medium in a single pass of the write head comprises supplying the write head of the system with a modulated write current comprising a plurality n of pulses of different magnitudes while the head moves past each element, thereby applying n different ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetic properties | aaaaa | aaaaa |

| magnetic field strengths | aaaaa | aaaaa |

| magnetic coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com