Ozone laundering system and method

a technology of ozone laundering and ozone, which is applied in the field of open-loop ozone laundering machines, can solve the problems of increased ozone contamination, increased ozone contamination, and increased ozone contamination of the environment, so as to reduce ozone contamination and control the effect of potentially harmful off-gassing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027]In the following description, like reference characters designate like or corresponding parts throughout the several views. Also in the following description, it is to be understood that such terms as “forward,”“rearward,”“left,”“right,”“upwardly,”“downwardly,” and the like are words of convenience and are not to be construed as limiting terms.

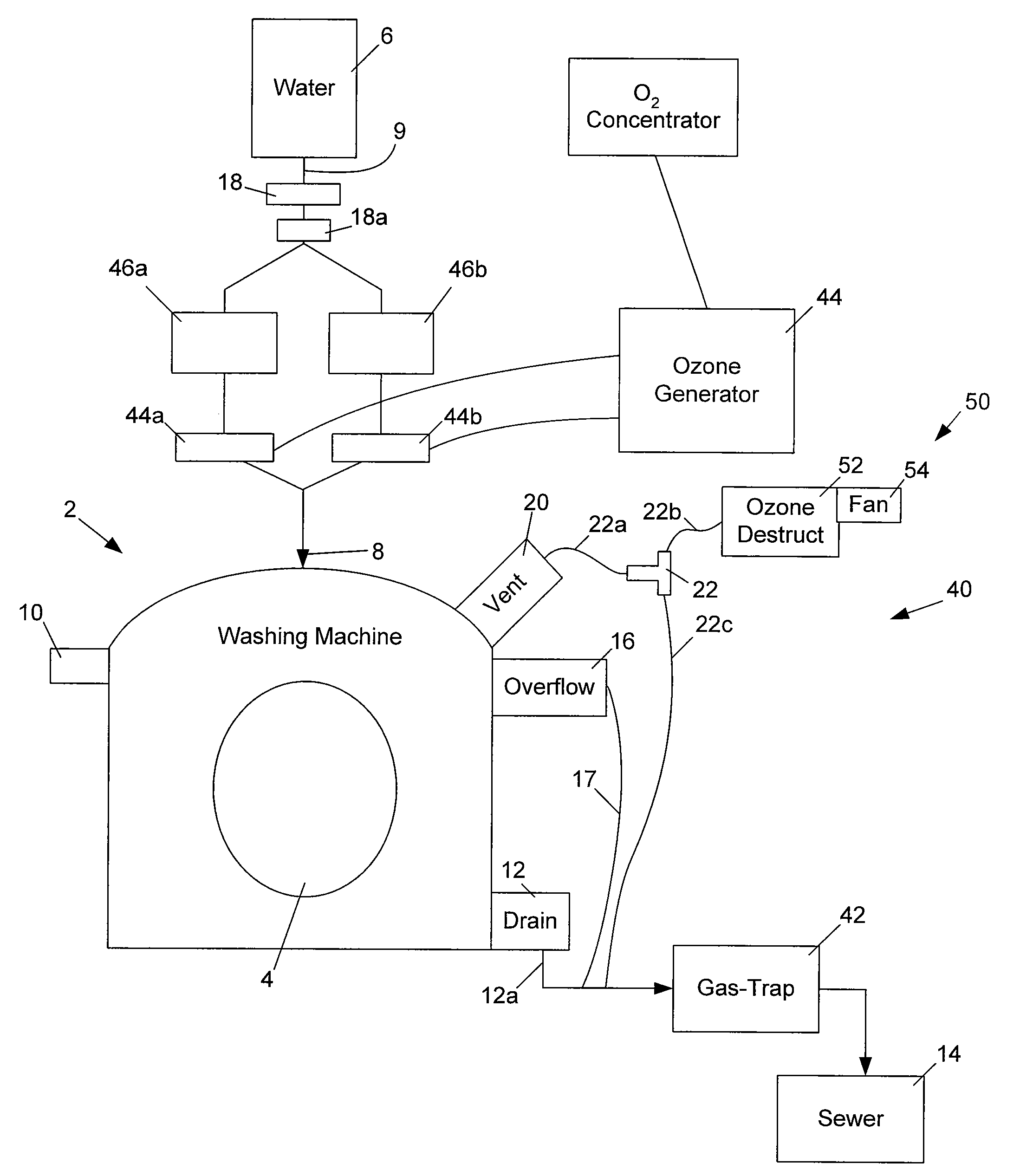

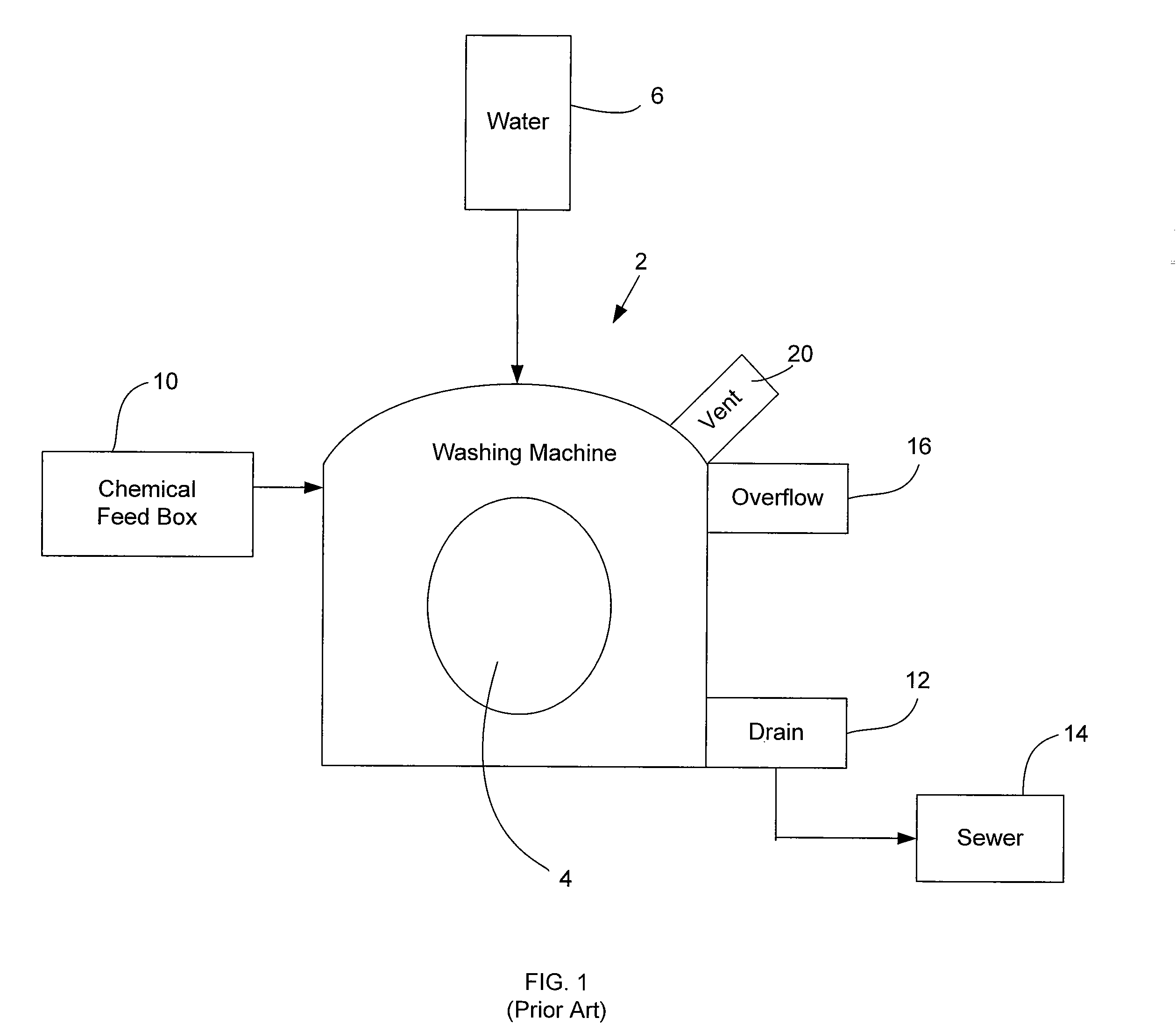

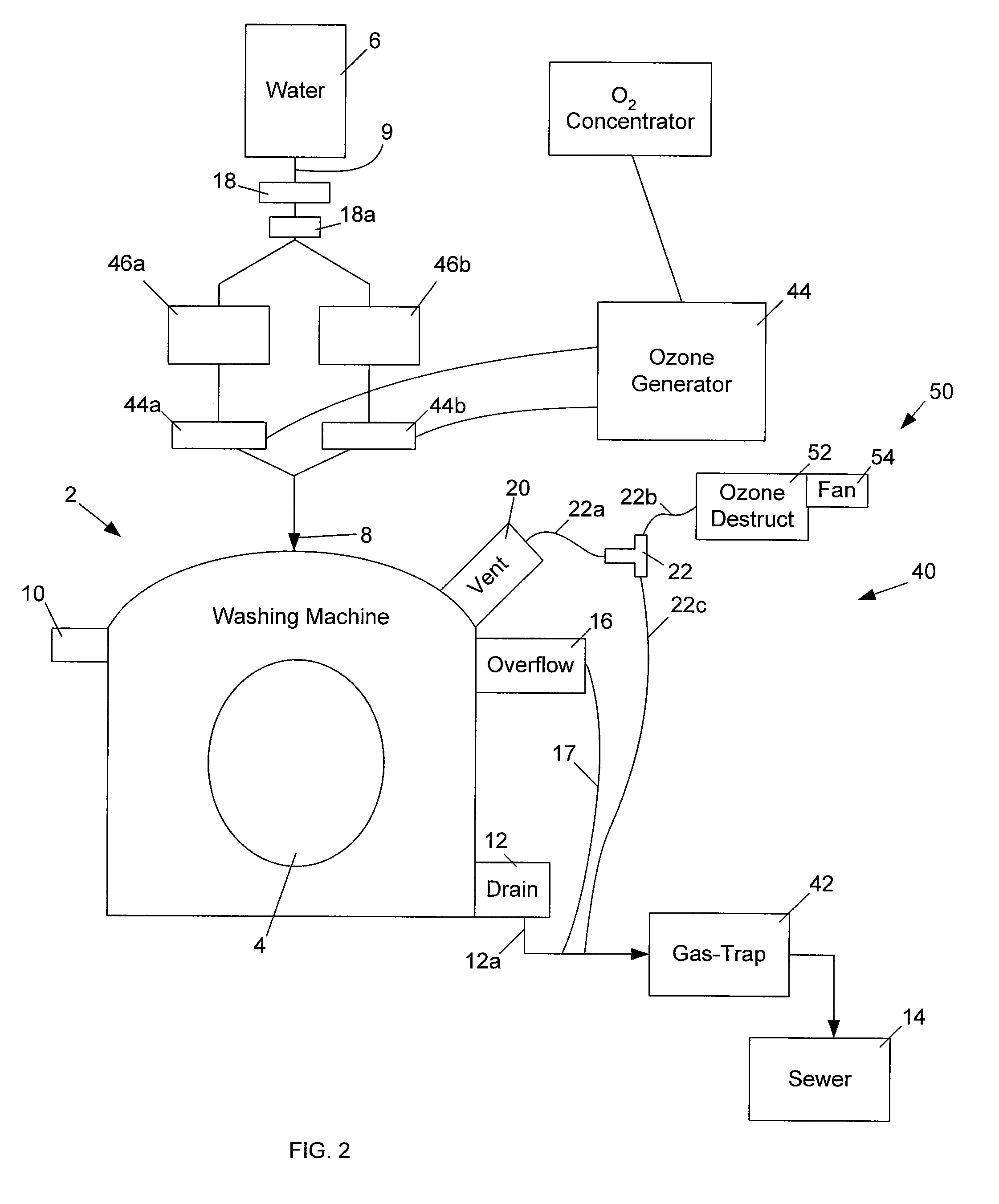

[0028]FIG. 1, discussed above, shows one type of traditional washing machine. FIG. 2 shows the traditional machine of FIG. 1 that has been converted according to the present invention to create an open-loop ozone washing system 40.

[0029]The conversion includes sealing traditional machine 2. As discussed above, traditional machines are not concerned with preventing the escape of excess or potentially harmful off-gas into the washroom environment. They commonly contain drains, vents, overflow drains, chemical feed boxes, etc., that could allow undesirable amounts of off-gas exposure or the undesirable release of ozonated water.

[0030]Sealin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com