Electrolytic apparatus for molten salt

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

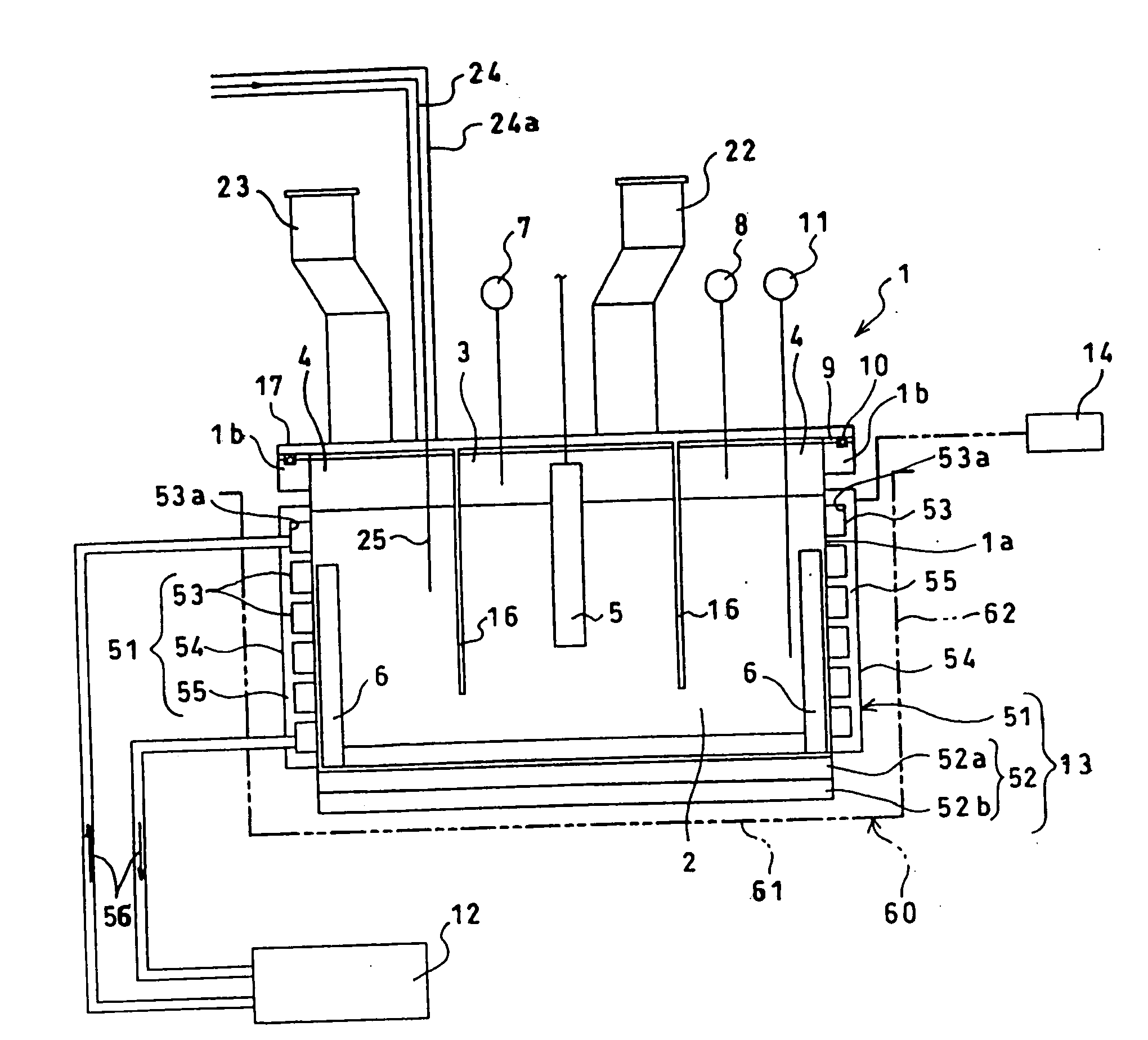

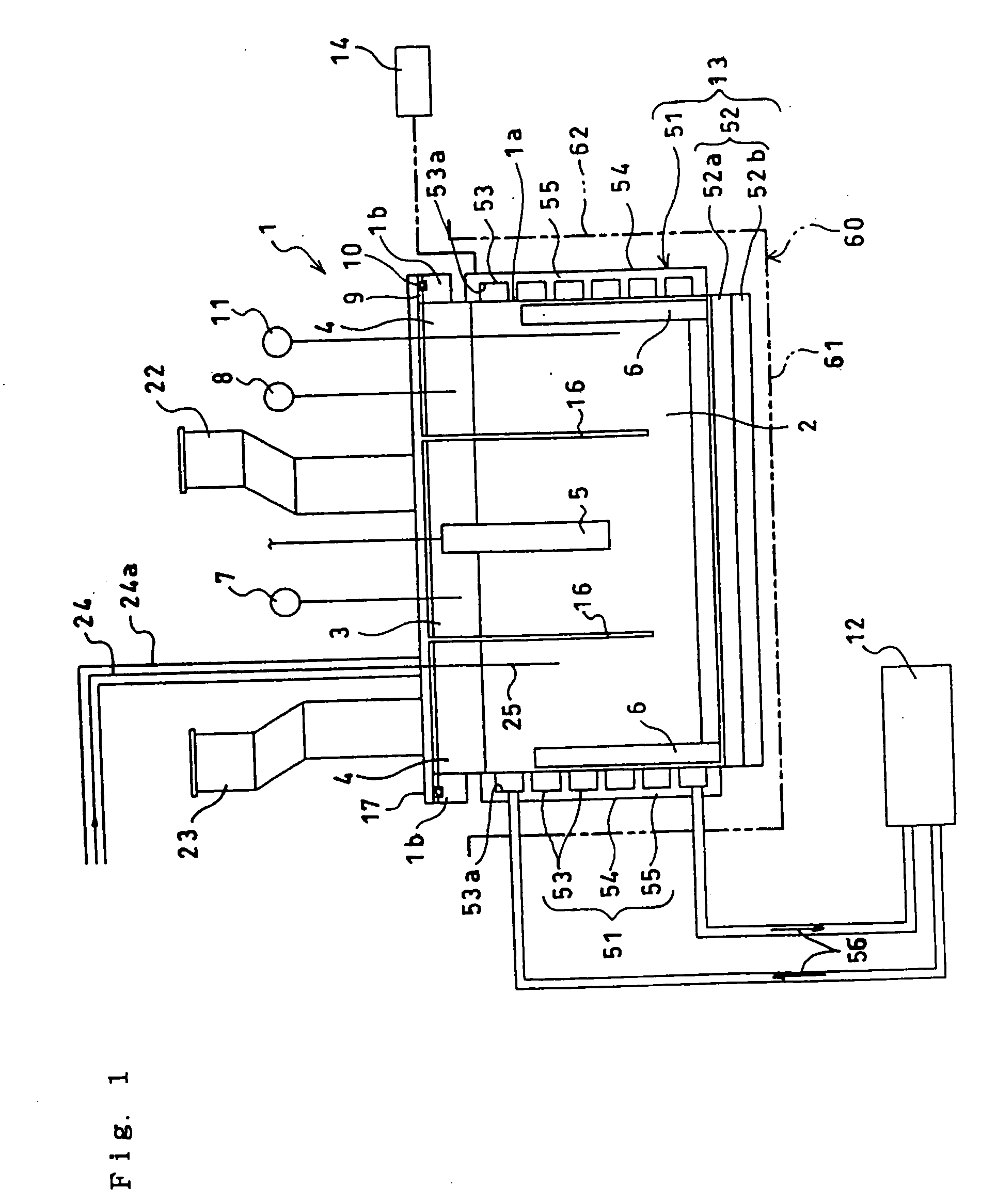

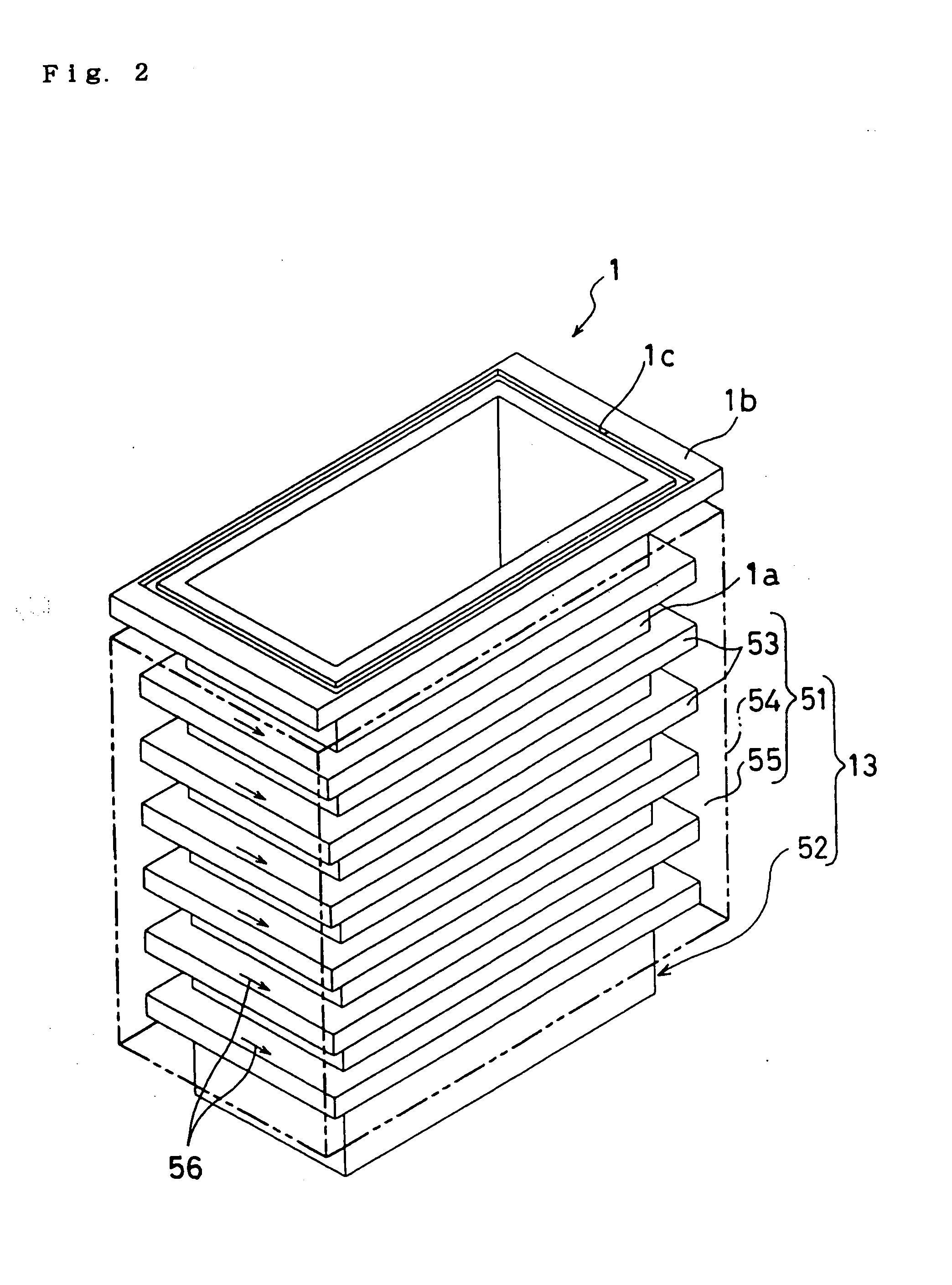

[0029]Hereinafter, based on the drawings 1-5, preferred embodiments of the present invention relating to the fluorine gas generator are described more in detail.

[0030]The construction of fluorine gas generator (an electrolytic apparatus for molten salt) is shown in FIG. 1. 1 is an electrolytic cell consisting of electrolytic cell body 1a and upper lid 17, and 2 is an electrolytic bath consisting of mixed molten salt made of KF-2HF type, 3 is an anode chamber, 4 is a cathode chamber, 5 is an anode, 6 is a cathode. 22 is an outlet port for C-1 generated fluorine gas in anode chamber 3. 11 is a thermometer to measure the temperature in the electrolytic bath 2, 13 is a heat exchanging means of electrolytic cell 1, 12 is an apparatus for warm water heating to supply the warm water for heat exchanging means 13. 51 is a warm water jacket disposed on the side of electrolytic cell 1, which constructs heat exchanging means, 52 is a heating parts (secondary heat exchanging means), which constr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Electric properties | aaaaa | aaaaa |

| Heat | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com