Process for preparing high-purity hydrogen by purifying palladium alloy membrane

A palladium alloy membrane, high-purity hydrogen technology, applied in the field of hydrogen membrane separation and purification, can solve the problems of insignificant advantages in re-investment and safety, failure to make full use of energy, and low operating flexibility, so as to promote chemical equilibrium movement and improve energy. Utilization and safety, the effect of low operating pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

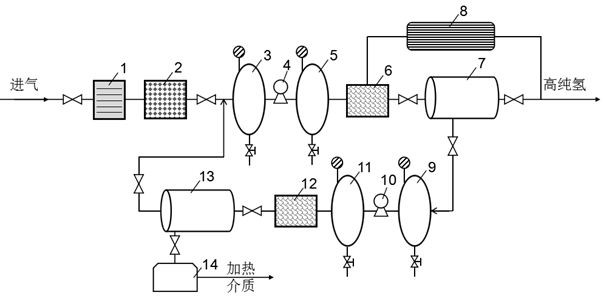

[0031] As shown in Figure 1, the palladium alloy membrane is used to purify hydrogen to obtain high-purity hydrogen. The device includes 1 is a desulfurization adsorption bed, 2 is a particle filter, 3 is a first gas storage tank, 4 is a first-stage booster pump, and 5 is a second storage tank. Gas tank, 6 is the primary heater, 7 is the primary metal palladium alloy membrane separator, 8 is the heat exchanger, 9 is the third gas storage tank, 10 is the secondary booster pump, 11 is the fourth gas storage tank , 12 is a secondary heater, 13 is a secondary metal palladium alloy membrane separator, and 14 is a regenerative heating furnace. The above device is connected by the pipeline according to figure 1 Connect in sequence. Among them, after the crude hydrogen enters the desulfurization adsorption bed, the crude hydrogen after filtering the particles enters the first gas storage tank, the pressurized and heated crude hydrogen enters the primary metal palladium alloy membrane...

Embodiment 2

[0035] The raw material gas is 81.7% crude hydrogen from methanol cracking gas, and the same device and process steps are used in the purification process as in Example 1.

[0036] After passing through the primary heater, the temperature is 290°C, and the pressure of the primary booster pump is 1.2MPa; after passing through the secondary heater, the temperature is 350°C, and the pressure after the secondary booster pump is 1.6MPa, and the secondary purification is 80% The hydrogen is fed into the primary inlet pipeline. Through heat exchange at the primary inlet and outlet and exhaust heat recovery, the temperature at the primary inlet can be increased to 74°C before passing through the primary heater. The purity of hydrogen after two-stage purification is 99.999%, the impurity content meets the national standard, and the utilization rate of crude hydrogen is 80%.

Embodiment 3

[0038] The raw material gas is 95.2% crude hydrogen from coal gas, and the same device and process steps are used in the purification process as in Example 1.

[0039] After passing through the primary heater, the temperature is 305°C, and the pressure of the primary booster pump is 0.9MPa; after passing through the secondary heater, the temperature is 310°C, and the pressure after the secondary booster pump is 1.0MPa, and the secondary purification yields 92% The hydrogen is fed into the primary inlet pipeline. Through heat exchange at the primary inlet and outlet and exhaust heat recovery, the temperature at the primary inlet can be increased to 58°C before passing through the primary heater. The purity of hydrogen after two-stage purification is 99.999%, the impurity content meets the national standard, and the utilization rate of crude hydrogen is 90%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com