Reforming and Hydrogen Purification System

a hydrogen purification system and reformer technology, applied in the field of steam reformers, can solve the problems of low power and low cost air supply for hydrogen rich fuel processing, and achieve the effects of low power, minimal pressure drop, and efficient heating of the reformer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

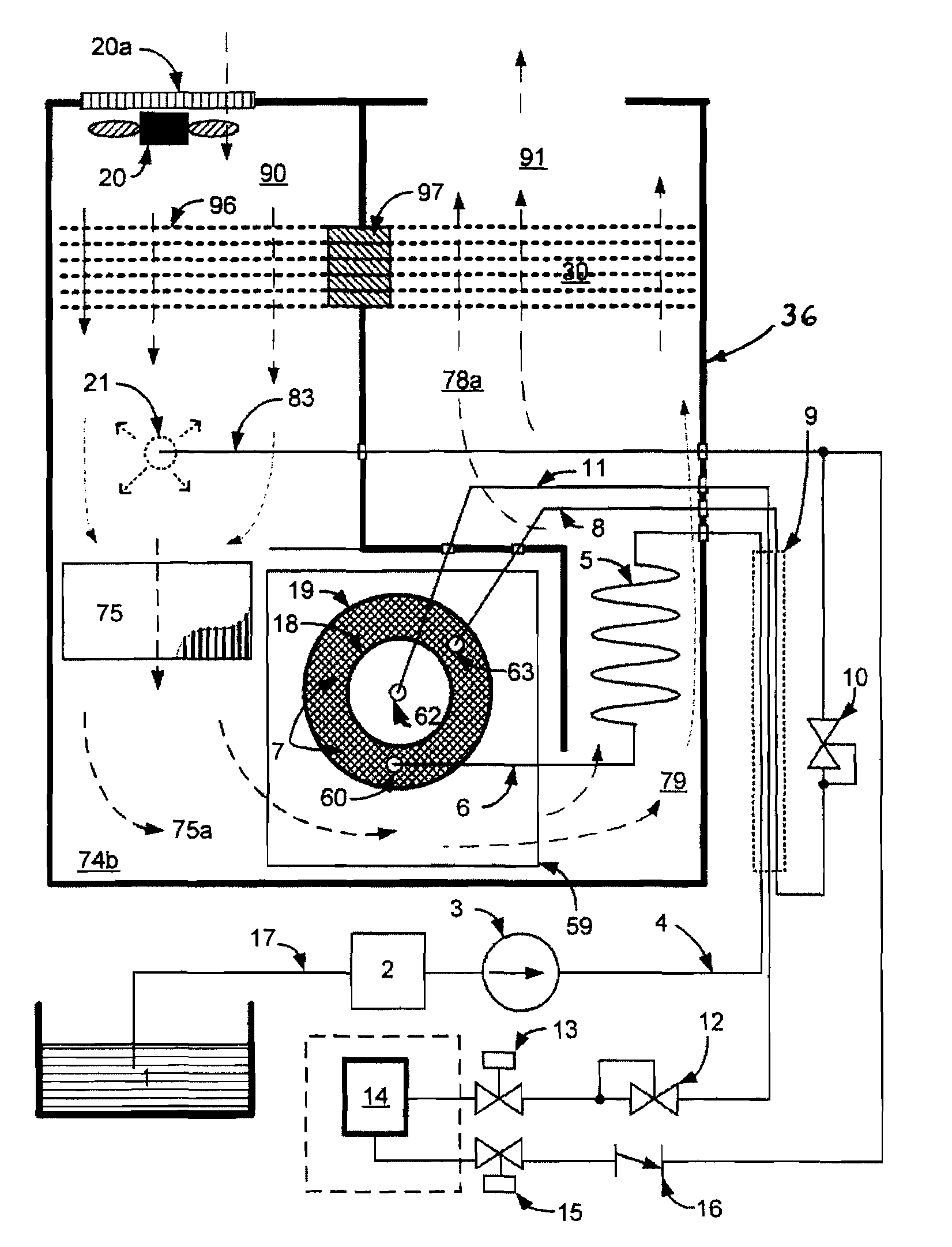

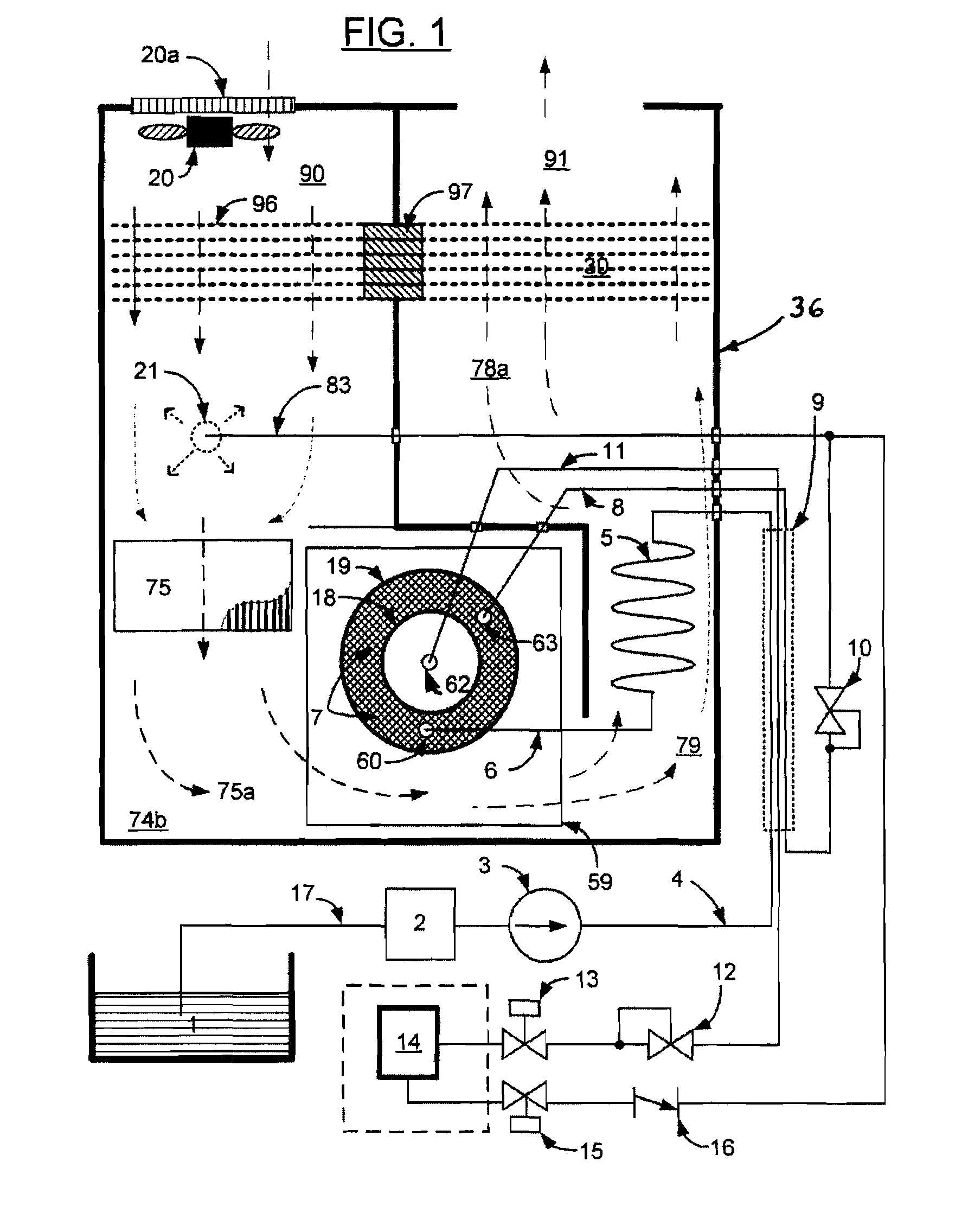

[0050]FIG. 1 is a simplified illustration of a system for generating purified hydrogen from a hydrogen rich fuel source 1 for consumption by device 14, which may, for example, be a fuel cell used for supplying electrical power to a load. The illustrated embodiment of FIG. 1 includes a unique hydrogen purifier 18 within a suitable support such as outer housing 36, in combination with the associated components.

[0051]The system of FIG. 1 includes a steam reformer having a reformer pressure vessel unit 19 which is operable to process fuel / water feedstock from a source 1. Although a common pump for the fuel and water is illustrated for the case where the fuel and water are miscible as a pre-mixed feedstock, it is understood that more than one pump may be used for the fuel and water, respectively, along with any needed flow and pressure monitoring means, with the fuel and water streams meeting together prior to arriving at the catalyst filled chamber 7. The pressure vessel unit 19 contain...

PUM

| Property | Measurement | Unit |

|---|---|---|

| light-off temperature | aaaaa | aaaaa |

| light-off temperature | aaaaa | aaaaa |

| thermally conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com