Grease composition, viscous agent, and mechanical element

a viscous agent and grease composition technology, applied in the direction of thickeners, liquid degasification, separation processes, etc., can solve the problems of insufficient selection of grease compositions for lubricating resin surfaces, inability to contribute to viscous agent lubricating performance, and easy access, etc., to achieve low friction performance and low wear performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0347]The invention will be further specifically described below with reference to the following Examples. Materials, reagents, amounts and proportions thereof, operations, and the like as shown in the following Examples can be properly changed so far as the gist of the invention is not deviated. Accordingly, it should not be construed that the scope of the invention is limited to the following specific examples.

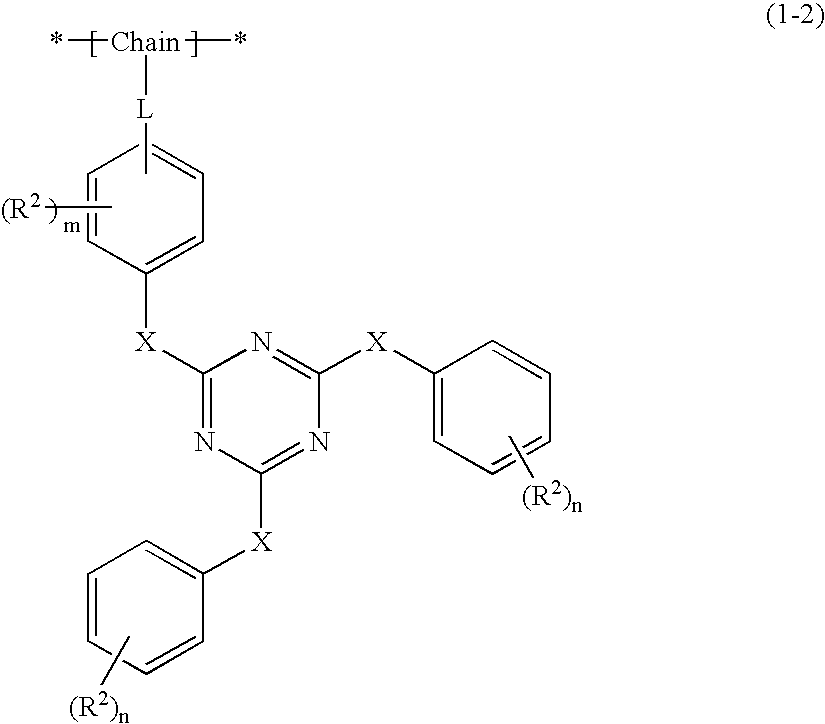

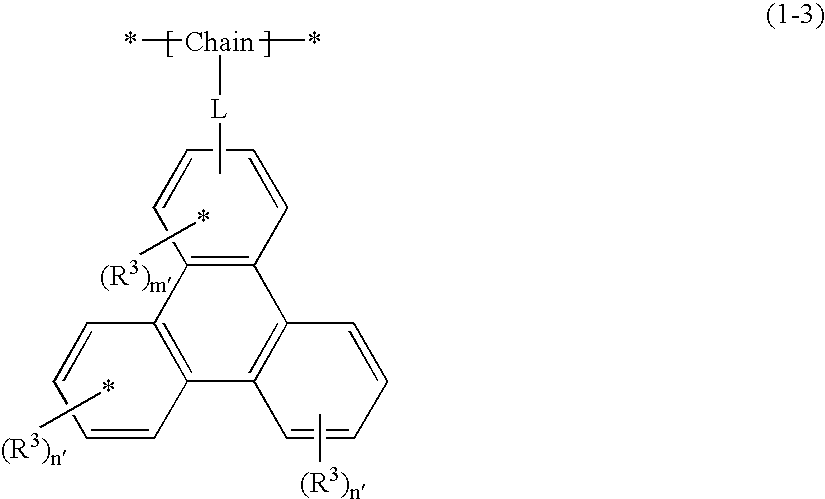

(1) Examples of First Invention

(1)-1 Examples Using Polymer Having Mesogen Structure in Side Chains

[0348]Greases (Example 1-1 to 1-11) having a formulation shown in Tables 1-1 to 1-3 below were respectively prepared. Beside these, greases (Comparative Examples 1-1 to 1-4) having a formulation shown in Table 1-4 below were respectively prepared, using various base oils for lubricant. The polymers used in Example 1 to 11 were produced according to the synthetic methods described in the above-described literatures. For example, DSP-37 was synthesized according to a method descr...

example 3-1

Evaluation of Performance of Grease Compositions

[0378]Using Exemplary Compounds LUB-7, LUB-11, LUB-14, LUB-29, LUB-127, LUB-38, LUB-154, LUB-156, and base oils for lubricant, greases (Examples 3-1 to 3-12) having a formulation shown in Tables 3-1 to 3-3 below were respectively prepared. Beside these, greases (Comparative Examples 3-1 to 3-4) having a formulation shown in Table 3-4 below were respectively prepared, using various base oils for lubricant.

[0379]The samples were subjected to friction test to thereby measure friction coefficient and depth of wear mark. The friction coefficient of each sample was measured using a reciprocating friction tester (SRV friction-wear tester), wherein the friction test was carried out under the test conditions below. Results of Examples 3-1 to 3-5 were shown in Table 3-1, results of Examples 3-6 to 3-10 were shown in Table 3-2, results of Examples 3-11 and 3-12 were shown in Table 3-3, and results of Comparative Examples 3-1 to 3-4 were shown in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| mean particle size | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| mesogen structure | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com