Two Line Gas Spectroscopy Calibration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

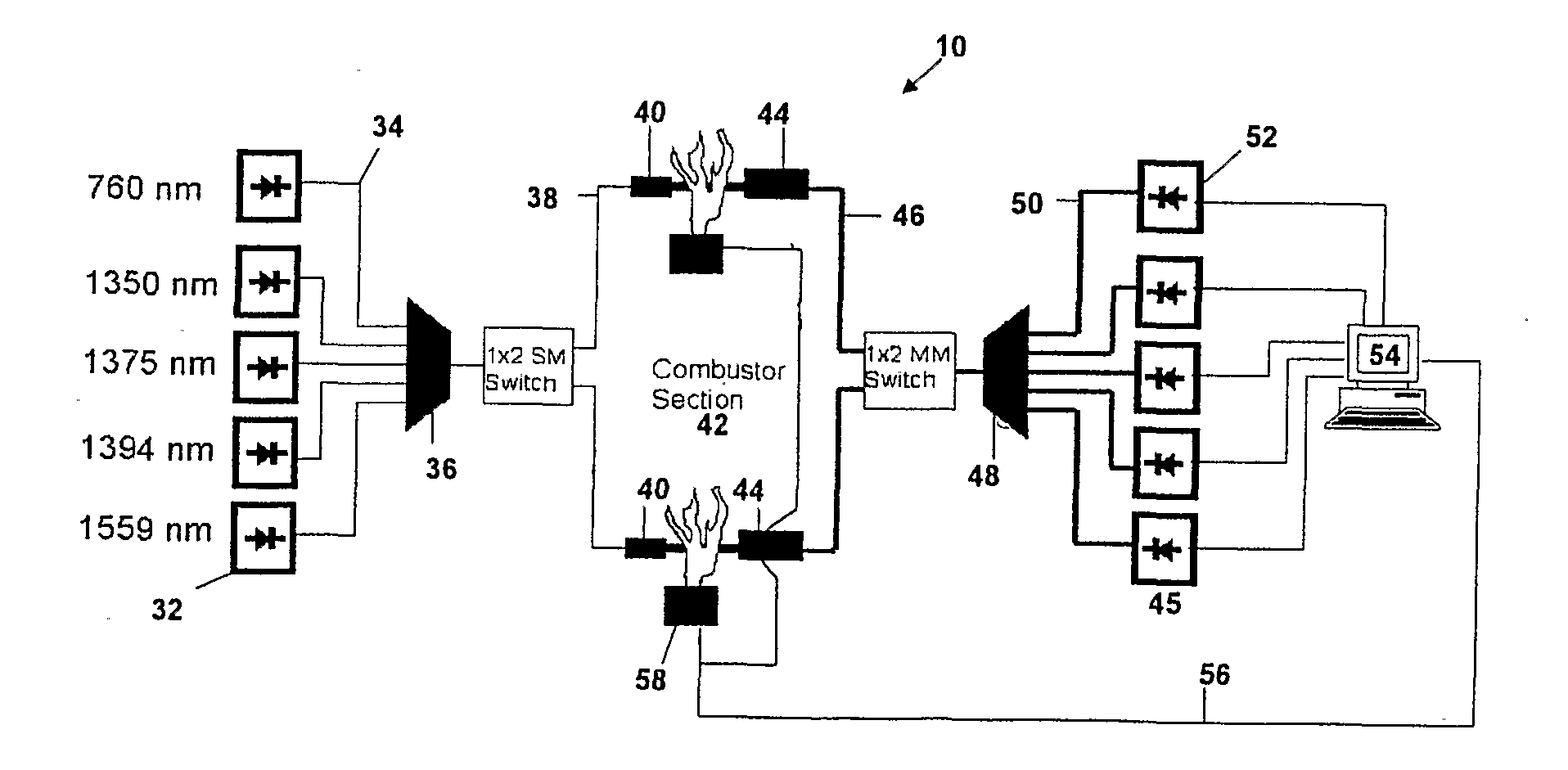

[0021]Ali apparatus 10 suitable for implementation of the present invention is shown in the block diagram of FIG. 1. The apparatus 10 includes a combustion chamber 12, which is shown in FIG. 1 as the furnace of a coal fired power plant. Access to the interior of the combustion chamber 12 is provided by one or more openings 14 formed in the walls of the combustion chamber 12. A laser 16 suitable for performing tunable diode laser absorption spectroscopy (TDLAS) is associated with the combustion chamber 12 and positioned at an opening 14 such that the laser 16 may project laser light through the opening 14 and combustion chamber 12, all as shown in FIG. 1. Opposite the combustion chamber 12 from the laser 16 is a detector 18 which is shown as associated with a second opening 14. Alternatively, the detector 18 could be associated with the same opening 14 as the laser 16 with the laser light being received after a reflected double pass through the combustion chamber 12.

[0022]The environ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com