Microwave process for intrinsic permeability enhancement and Hydrocarbon extraction from subsurface deposits

a technology of intrinsic permeability and hydrocarbon extraction, which is applied in the direction of fluid removal, earthwork drilling and mining, and wellbore/well accessories, etc., can solve the problems of relatively ineffective control heating and removal of hydrocarbons, microwave generators, etc., and achieve selective and rapid heating and enhance the permeability of subterranean rock

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

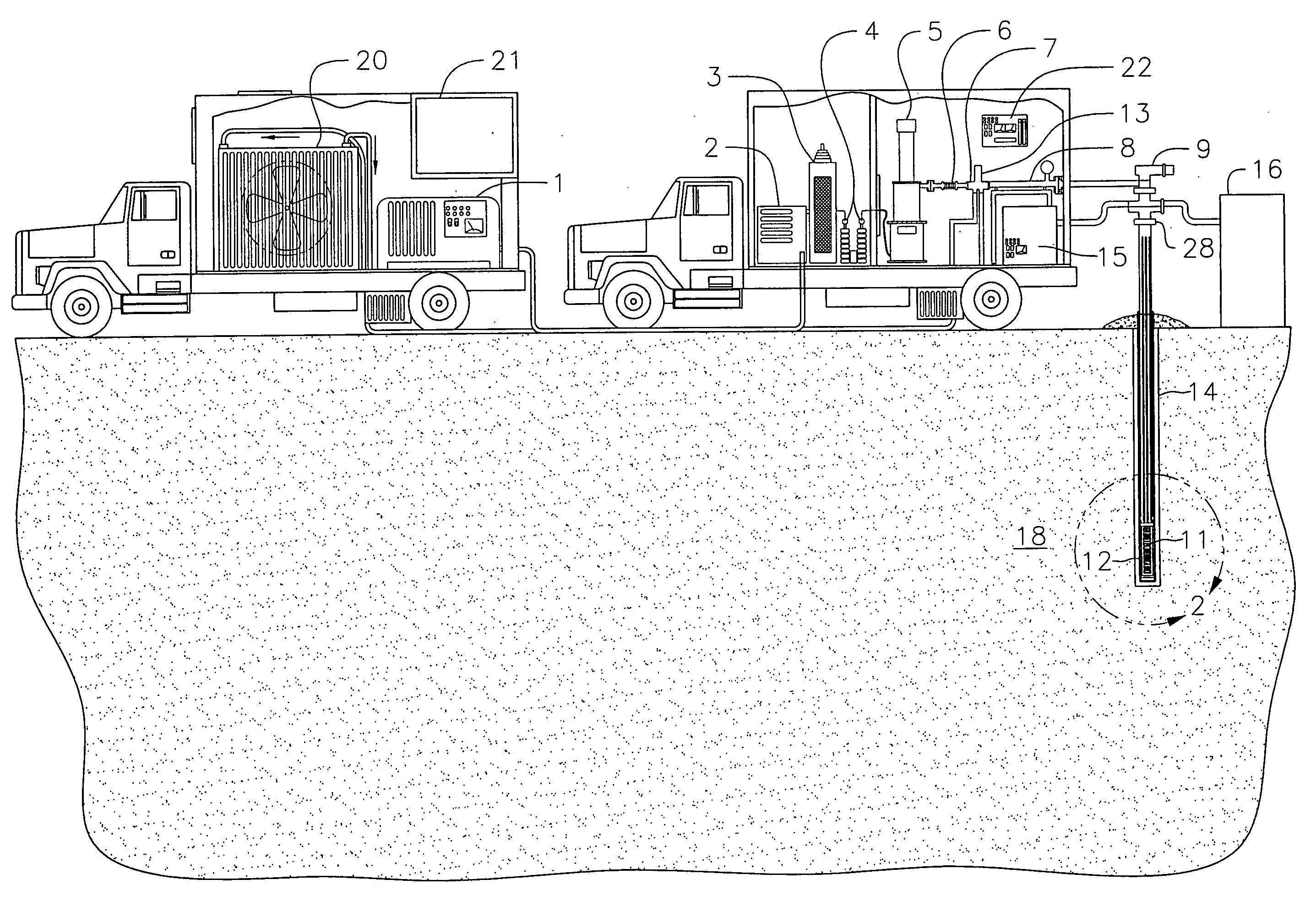

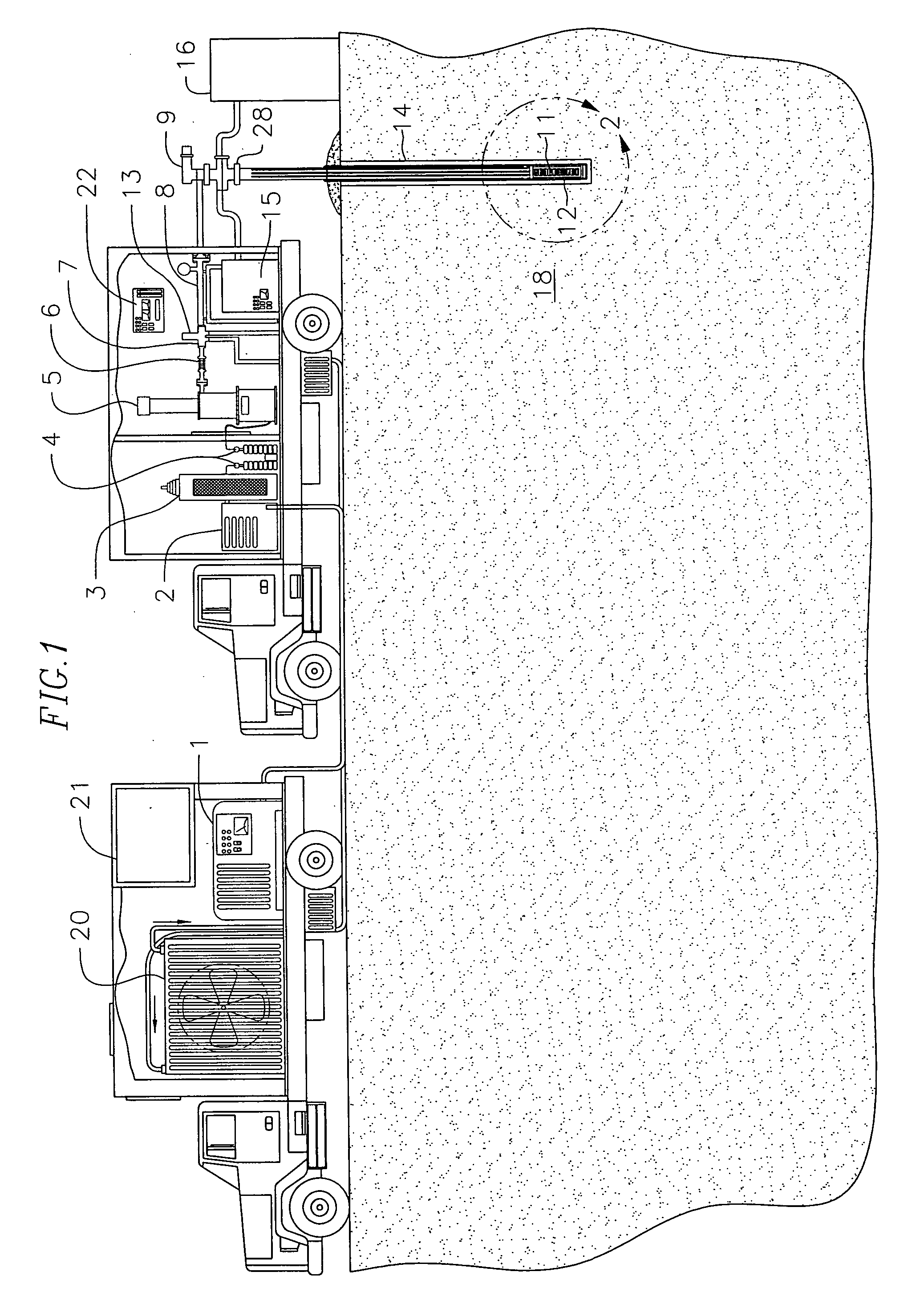

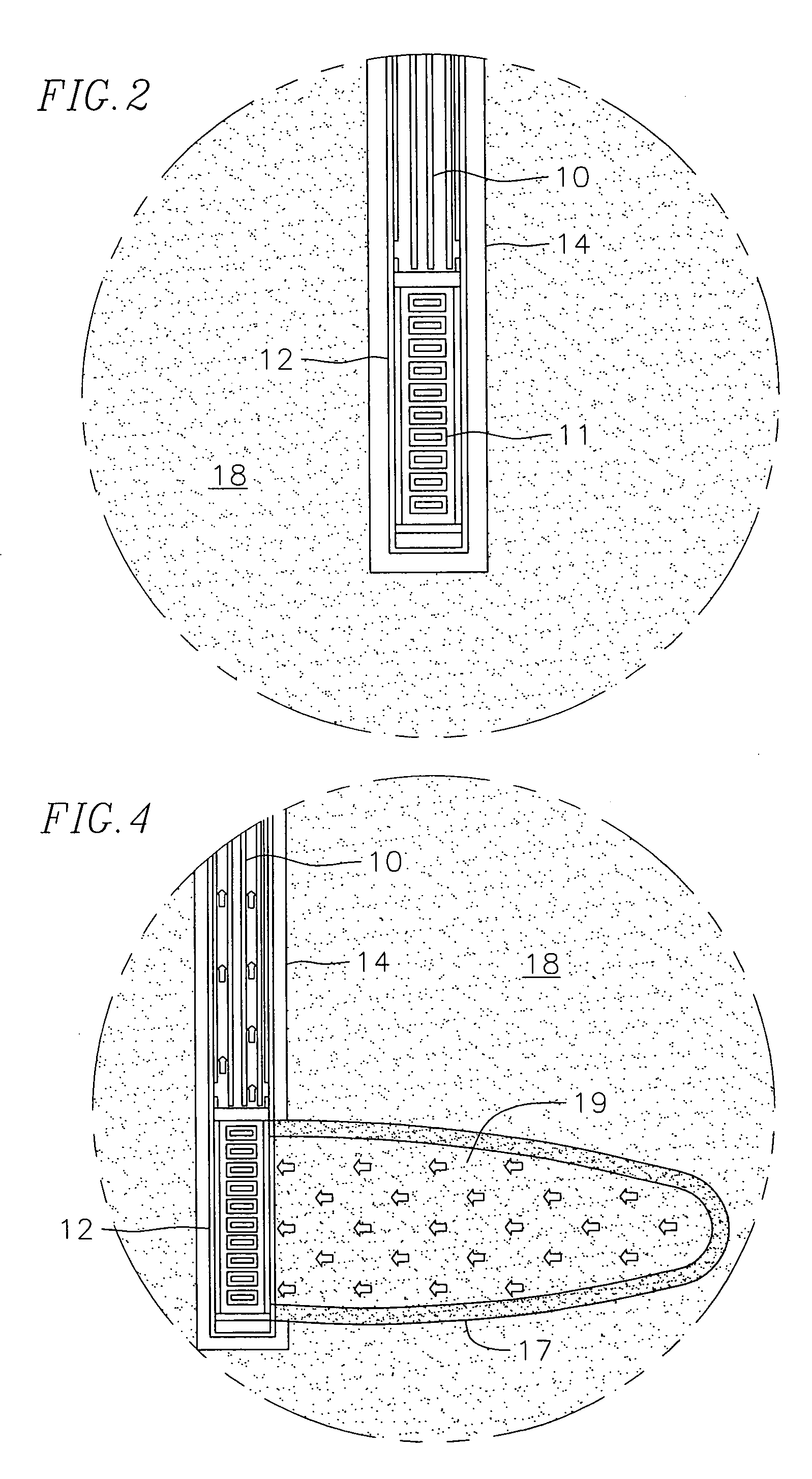

[0031]The specific embodiments of the hydrocarbon recovery system are illustrated in the drawings and will be described in detail herein. FIG. 1 illustrates the major components of a mobile hydrocarbon recovery system. A 400 cycle turbine generator 1, or some similar source, supplies electrical power for the system. The output of the generator 1 is applied to a transformer / filter unit 3 under the control of a control unit 2. A crowbar electrical circuit 4 at the output of the transformer / filter unit 3 prevents an over voltage condition at the output of the transformer / filter unit 3 from damaging circuits coupled to its output. Once triggered, crowbars 4 depend on overload-limiting circuitry, and if that fails, the system is protected by a line fuse or circuit breaker (not shown).

[0032]A high power (½ megawatt or greater) microwave source 5 (klystron) provides electrical energy down a waveguide 6. The source 5 may be a typical klystron with an efficiency between 40% and 50%. Preferab...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com