Method for applying a stress layer to a semiconductor device and device formed therefrom

a stress layer and semiconductor technology, applied in the field of semiconductor devices, can solve the problems of significant limitations in the size and operation speed of such devices, and achieve the effect of reducing power consumption and increasing operating speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

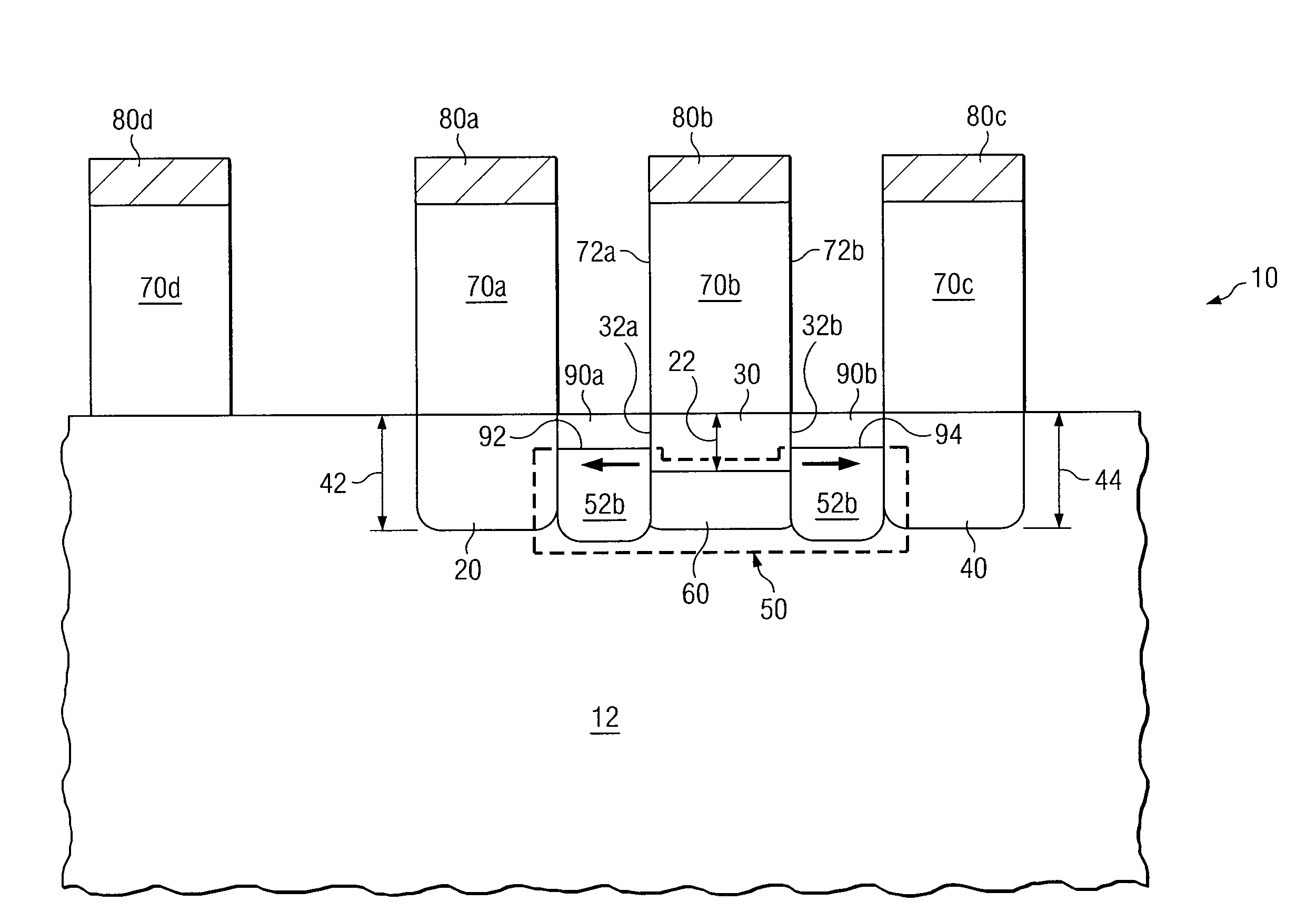

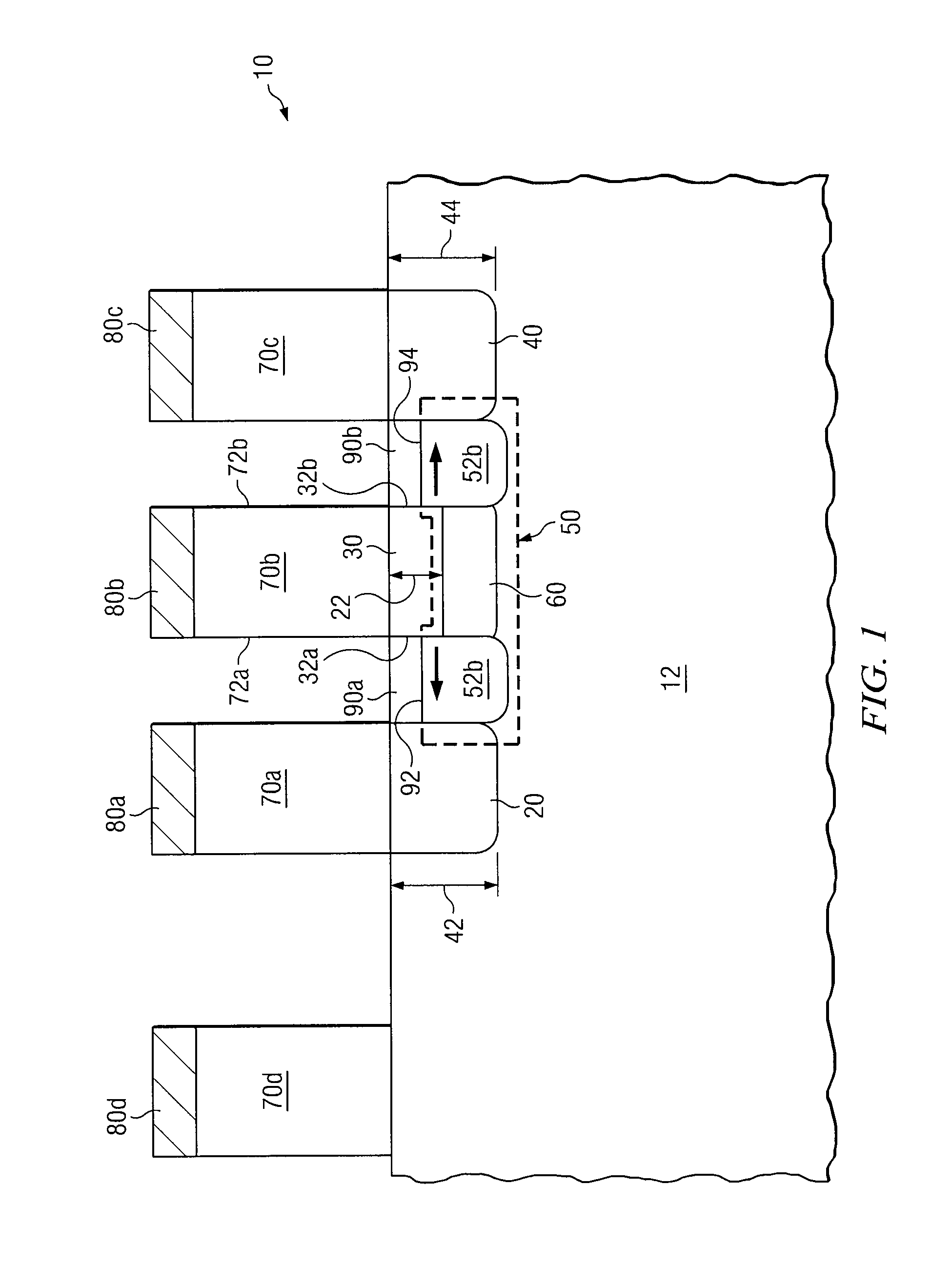

[0010]FIG. 1 shows a cross-sectional view of a semiconductor device 10 according to a particular embodiment of the present invention. As shown in FIG. 1, semiconductor device 10 includes a substrate 12, a source region 20, a gate region 30, a drain region 40, a conducting region 50, polysilicon regions 70a-d, and contacts 80a-d. Additionally, conducting region 50 includes link regions 52a-b and a channel region 60. In general, voltages applied to contacts 80a-d of semiconductor device 10 affect the conductivity of channel region 60 and, when appropriate voltages are applied to contacts 80a-d, a current flows between source region 20 and drain region 40 through conducting region 50. While semiconductor device 10 may represent any appropriate form of electronic device that has the described structure and / or provides the described functionality, in particular embodiments, semiconductor device 10 represents a junction field-effect transistor (JFET).

[0011]As discussed in more detail belo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com