Semiconductor Device, Manufacturing Method Thereof, and Measuring Method Thereof

a technology of semiconductor devices and manufacturing methods, applied in the direction of individual semiconductor device testing, semiconductor/solid-state device testing/measurement, instruments, etc., can solve the problems of difficult measurement of properties, difficult method use, and pricking of teg manufactured over flexible substrates, etc., to achieve the effect of little deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment mode 1

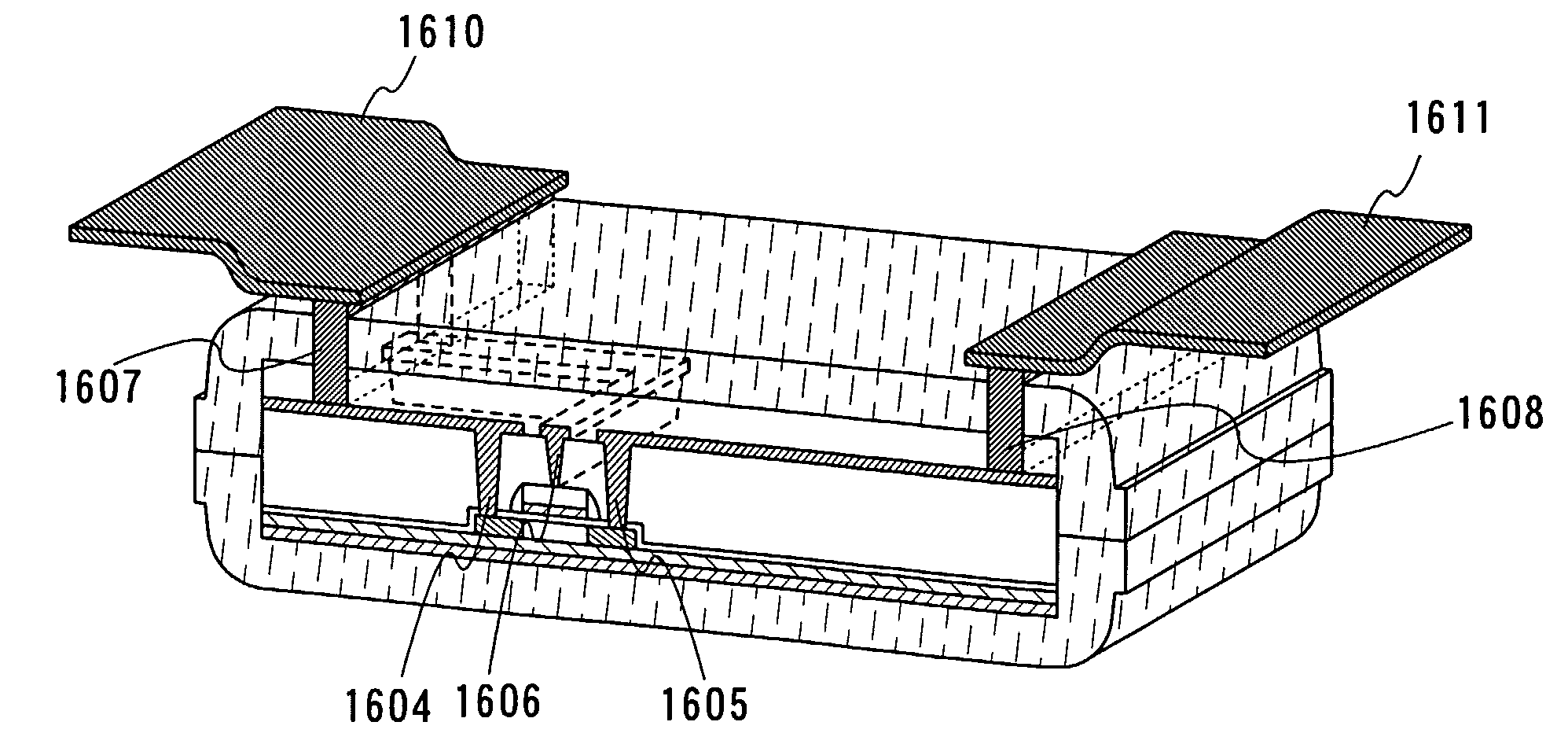

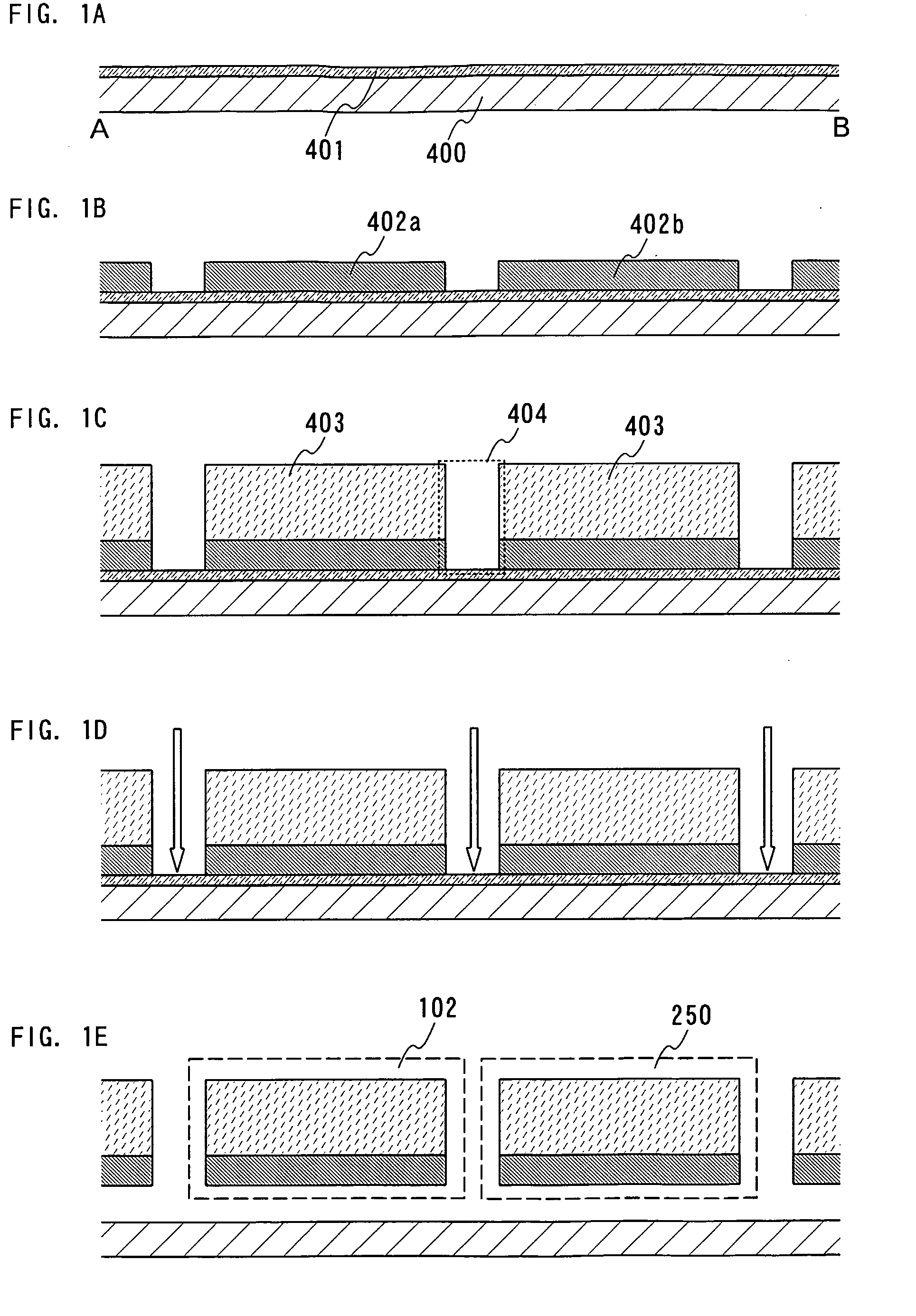

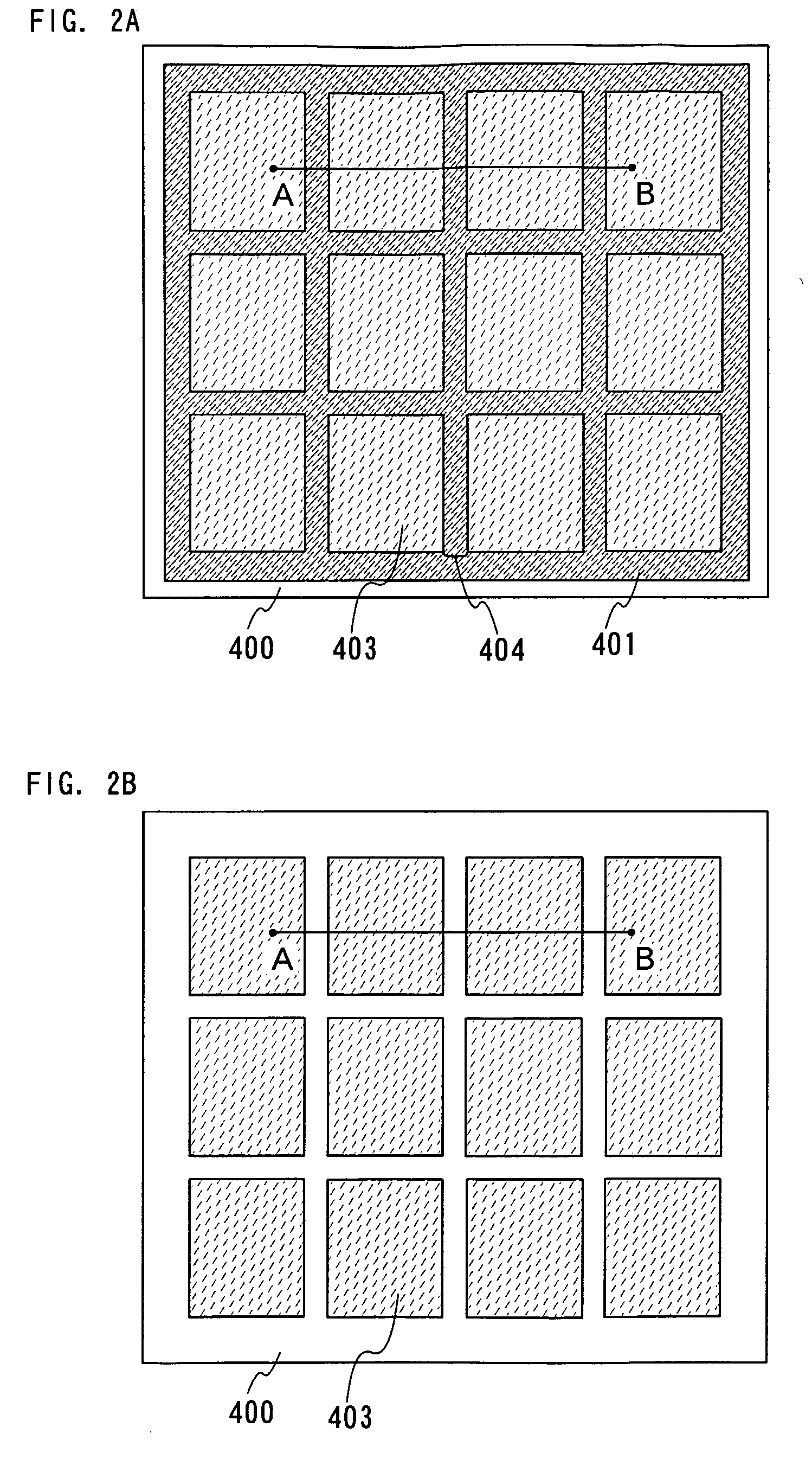

[0056]In Embodiment Mode 1, an example of a process will be explained, in which a chip for a TEG is manufactured at the same time as a plurality of wireless chips is manufactured over a flexible substrate.

[0057]First, a peeling layer 401 is formed over a substrate 400 shown in FIG. 1A. Since the substrate used here is removed in a later step, it is not limited to a flexible substrate, and a glass substrate, a quartz substrate, a ceramic substrate, or the like can be used. Further, a metal substrate including stainless steel or a semiconductor substrate on which an insulating film is formed may be used.

[0058]Next, over the peeling layer 401, an element layer 402a which is a part of an element 102 to be a wireless chip shown in FIG. 1E is formed, while an element layer 402b which is a part of an element 250 to be a chip for a TEG shown in FIG. 1E is formed (see FIG. 1B). The element 102 to be a wireless chip mainly includes a thin film circuit having a transistor or the like, and an a...

embodiment mode 2

[0079]In Embodiment Mode 2, a chip for a TEG is manufactured at the same time as a plurality of wireless chips is manufactured over a flexible substrate, and an example of how a result of a characteristic evaluation or a defect analysis on the chip for a TEG is reflected, will be described.

[0080]In a case of obtaining an anticipated characteristic result by the characteristic evaluation or the defect analysis on the chip for a TEG, the wireless chips manufactured at the same time as the chip for a TEG is manufactured, can be shipped, as it is, as products. In this case also, after cutting a terminal portion of the chip for a TEG, an element layer is again sealed. Alternatively, after separating a wiring substrate having flexibility, an element layer is again sealed with a film. Accordingly, the chip manufactured as a chip for a TEG can be used as a wireless chip, and yield can be improved.

[0081]In a case where an anticipated response result cannot be obtained by the characteristic e...

embodiment 1

[0082]In Embodiment 1, a process up to forming a plurality of wireless chips and a chip for a TEG as explained in Embodiment Mode 1, will be described in more detail.

[0083]First, a substrate 400 is prepared and a peeling layer 401 is formed over the substrate 400 as shown in FIG. 1A. Specifically, a glass substrate such as barium borosilicate glass, or aluminoborosilicate glass, a quartz substrate, a ceramic substrate, or the like can be used as the substrate 400. Further, a metal substrate such as stainless steel or a semiconductor substrate provided with an insulating film on its surface may also be used. In addition, although a flexible substrate made from a synthetic resin such as plastic generally tends to have lower heat-resistance than that of the above-described substrate material, it can also be used as long as it can withstand a process temperature in the manufacturing process. The surface of the substrate 400 may be planarized by polishing using a CMP method or the like.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com