External hydraulic pump for motor vehicle transmission

a technology of hydraulic pump and transmission, which is applied in the direction of pump, positive displacement liquid engine, machine/engine, etc., can solve the problems of internal pump damage, rob the power from the engine during use, and the internal pump cannot function, so as to improve the operating efficiency and operating economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

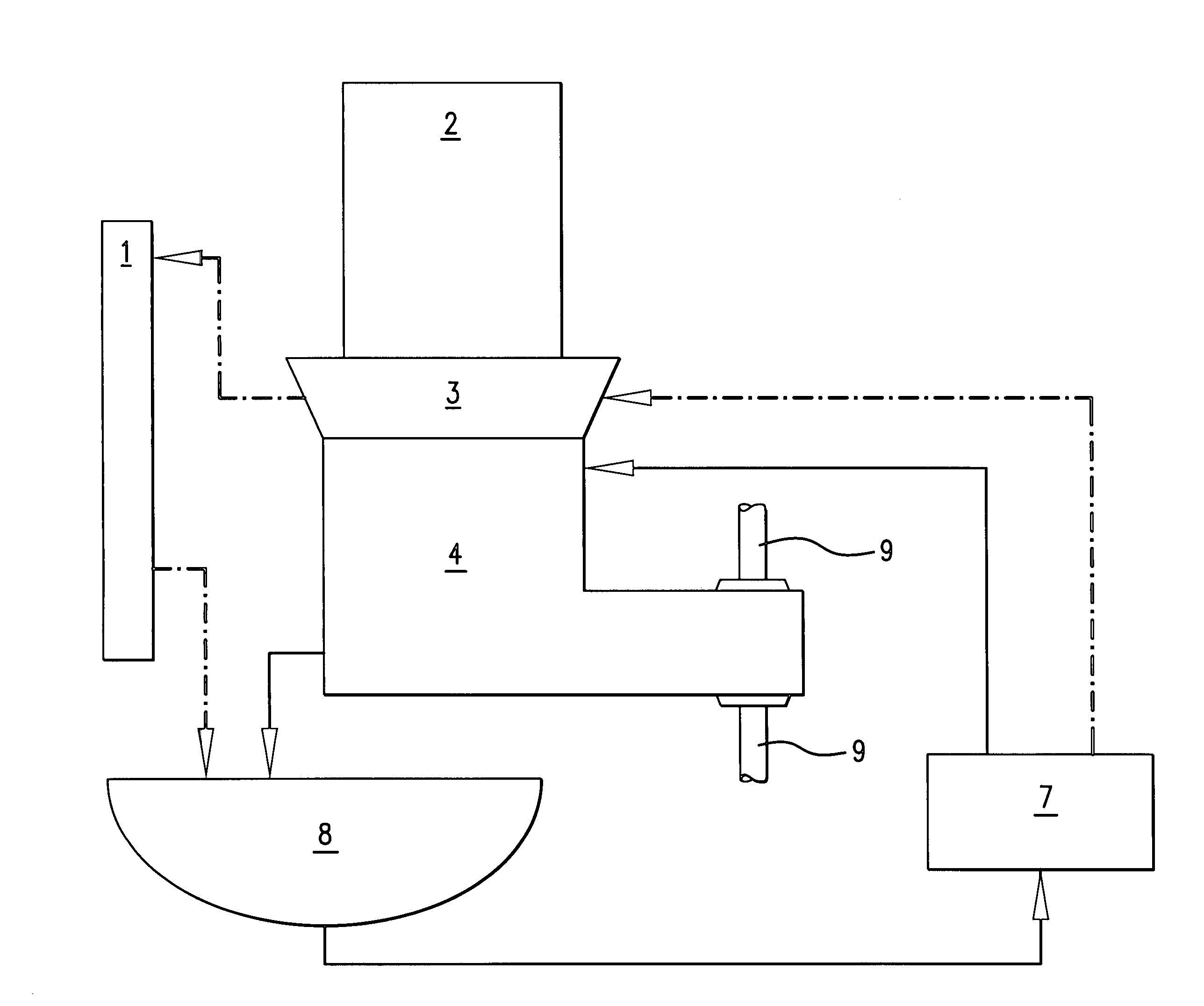

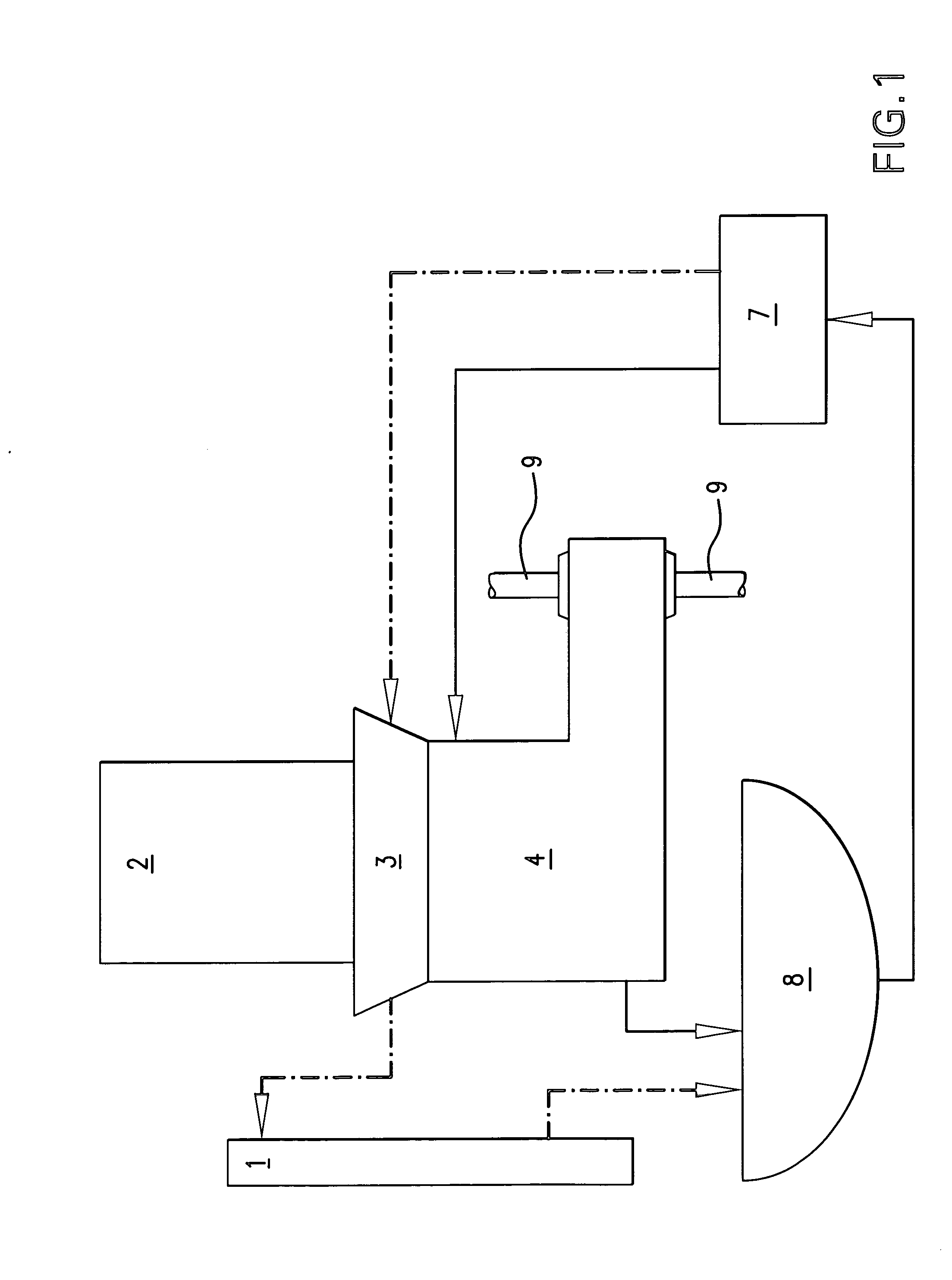

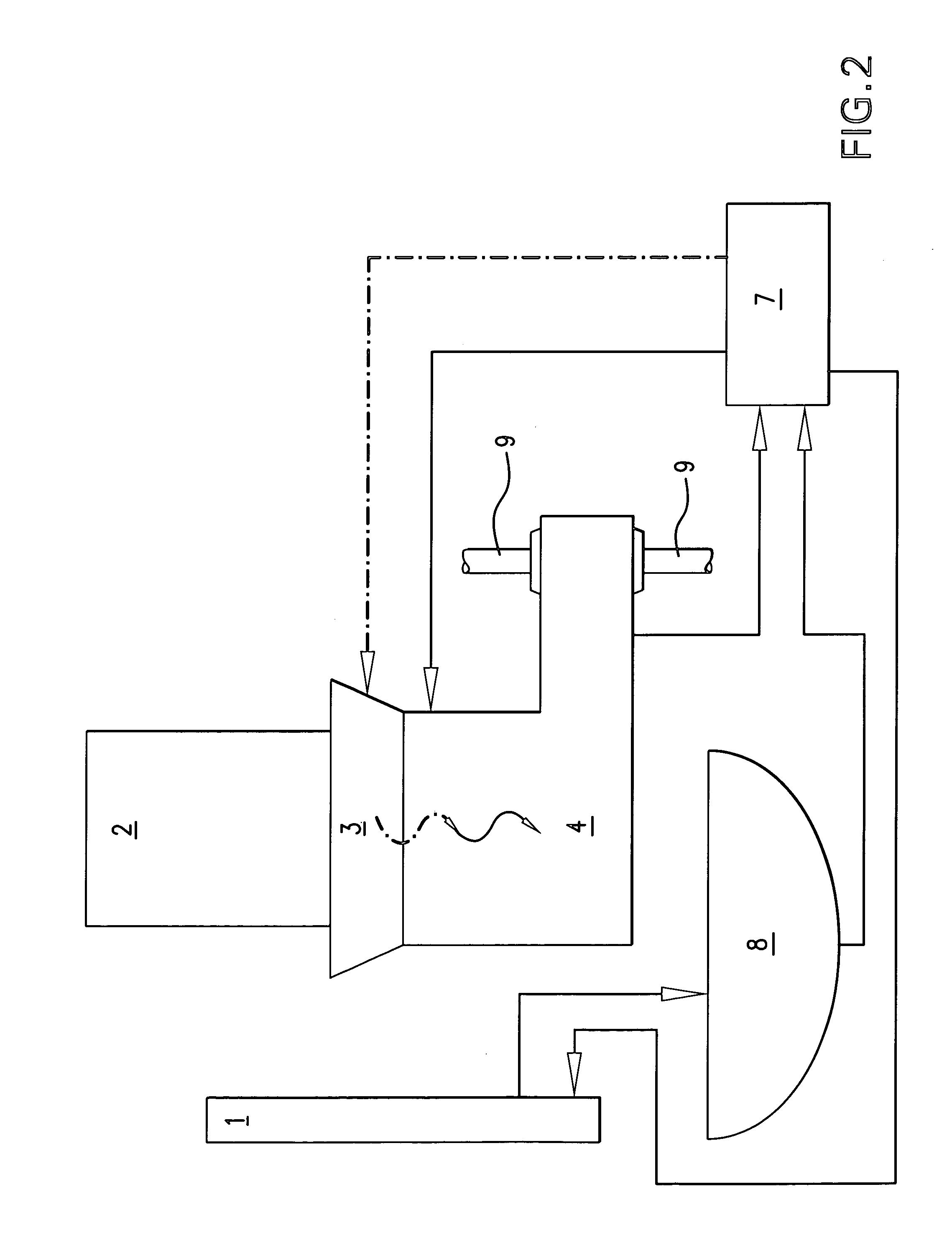

[0018]The preferred embodiments of the invention as illustrated in the drawings show an externally mounted electric pump mounted in the engine compartment near the engine and transmission of a motor vehicle, and not mounted within the transmission or torque converter housing. A high pressure fluid supply line runs from the pump to the torque converter in the bell housing which surrounds the torque converter. This provides the pressurized hydraulic fluid necessary to operate the torque converter and transmission and to lubricate the necessary parts therein. Once the fluid is used by the torque converter and transmission, it is withdrawn from the transmission housing and passed through a heat exchanger for cooling and returned to the storage tank which serves as the supply for the electrical pump.

[0019]Depending on main pump location, an external low pressure fluid transfer pump may be needed to move fluid from the transmission to the main external pump. The main pump may be of two-st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com