Fabric and yarn structures for improving signal integrity in fabric-based electrical circuits

a technology of fabric-based electrical circuits and conductive yarns, applied in the direction of yarn, weaving, conductive pattern formation, etc., can solve the problems of unsuitability for incorporation in a fabric, and achieve the effects of improving signal integrity in fabric-based electrical circuits, reducing crosstalk in fabric-based circuits, and improving conductive yarn structures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

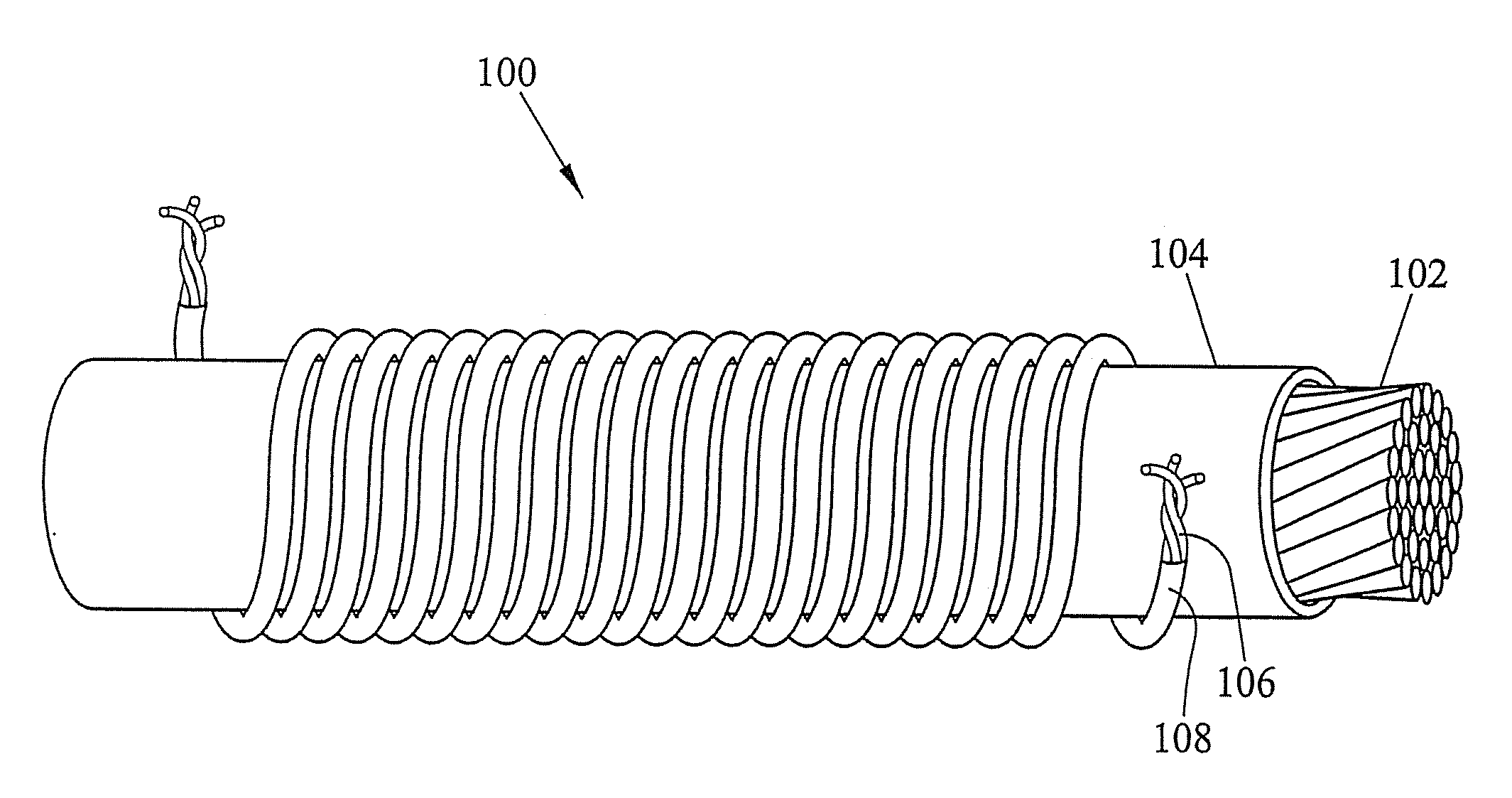

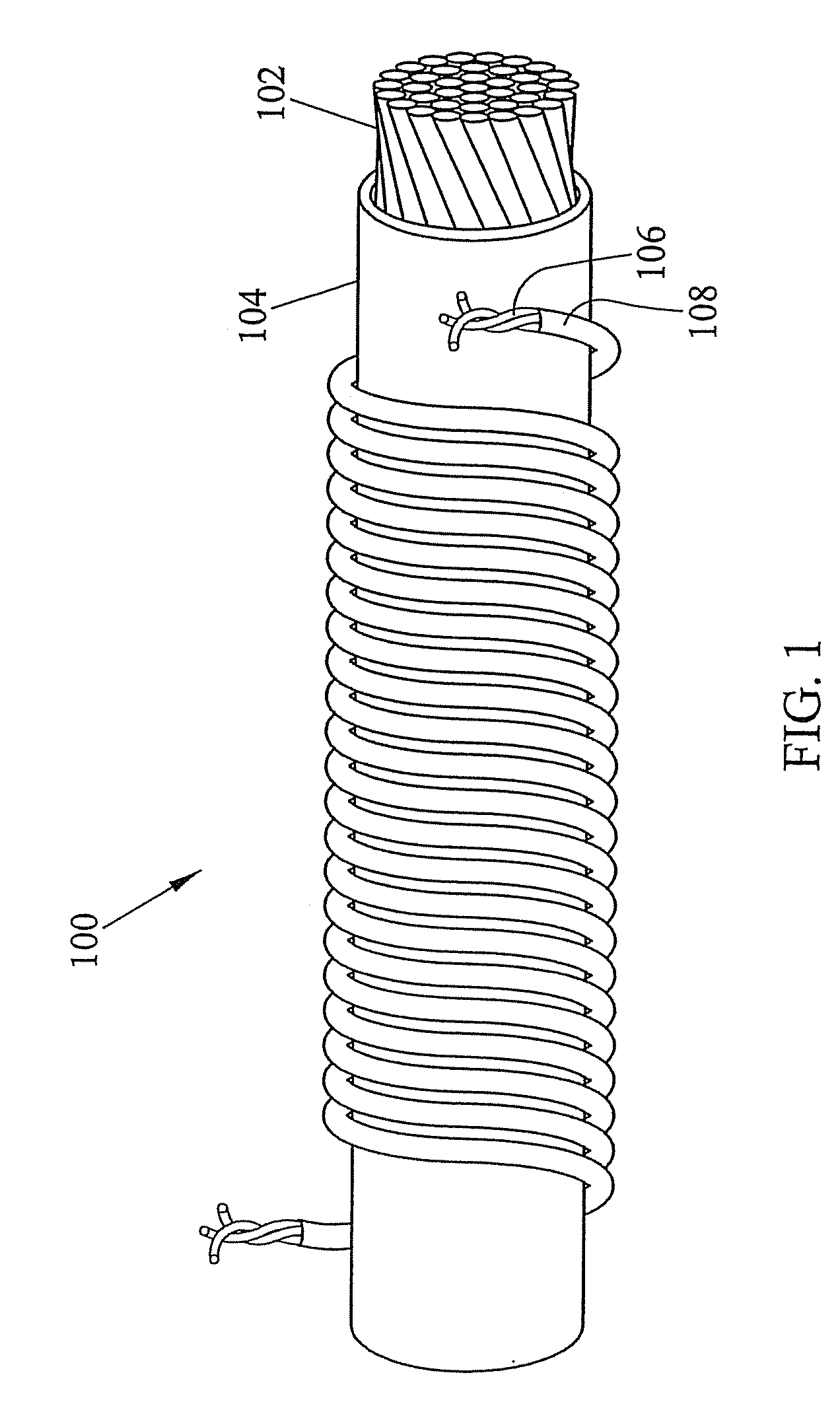

[0055]The present invention includes conductive yarn structures for improving signal integrity in fabric-based electrical networks. FIG. 1 illustrates an example of one conductive yarn structure suitable for improving signal integrity in fabric-based electrical networks according to an embodiment of the present invention. Referring to FIG. 1, a conductive yarn structure 100 comprises a coaxial conductive yarn structure. Coaxial conductive yarn structure 100 includes an inner conductive yarn 102 surrounded by an insulating layer 104 and an outer conductive yarn 106, which is preferably also surrounded by an insulating layer 108. Inner conductive yarn 102 includes a plurality of conductive strands being twisted together. The conductive strands may be made of any suitable conductive material, such as such as copper, gold, steel, aluminum, silver, or iron or conductive polymers (inherently conductive polymeric materials, such as polypyrrole, polyacetylene, polythiophene and polyaniline,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distances | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| conductive | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com