Integrated system for routine maintenance of mechanized equipment

a mechanized equipment and integrated system technology, applied in the direction of structural/machine measurement, instruments, data processing applications, etc., can solve the problems of harsh operating conditions direct and negative impact of commercial outdoor applications, and the routine exposure of mechanized outdoor application vehicles to environmental variables

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

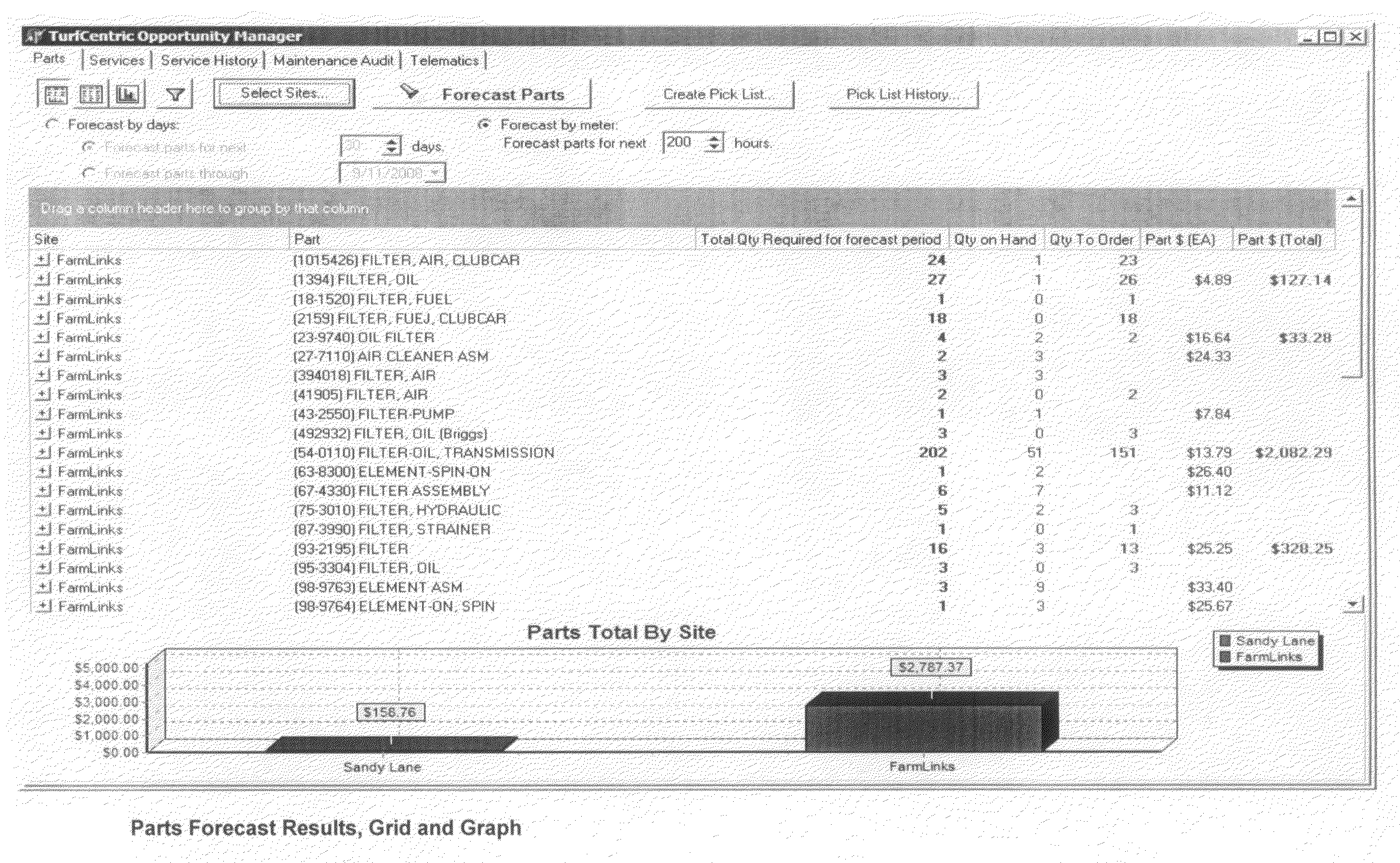

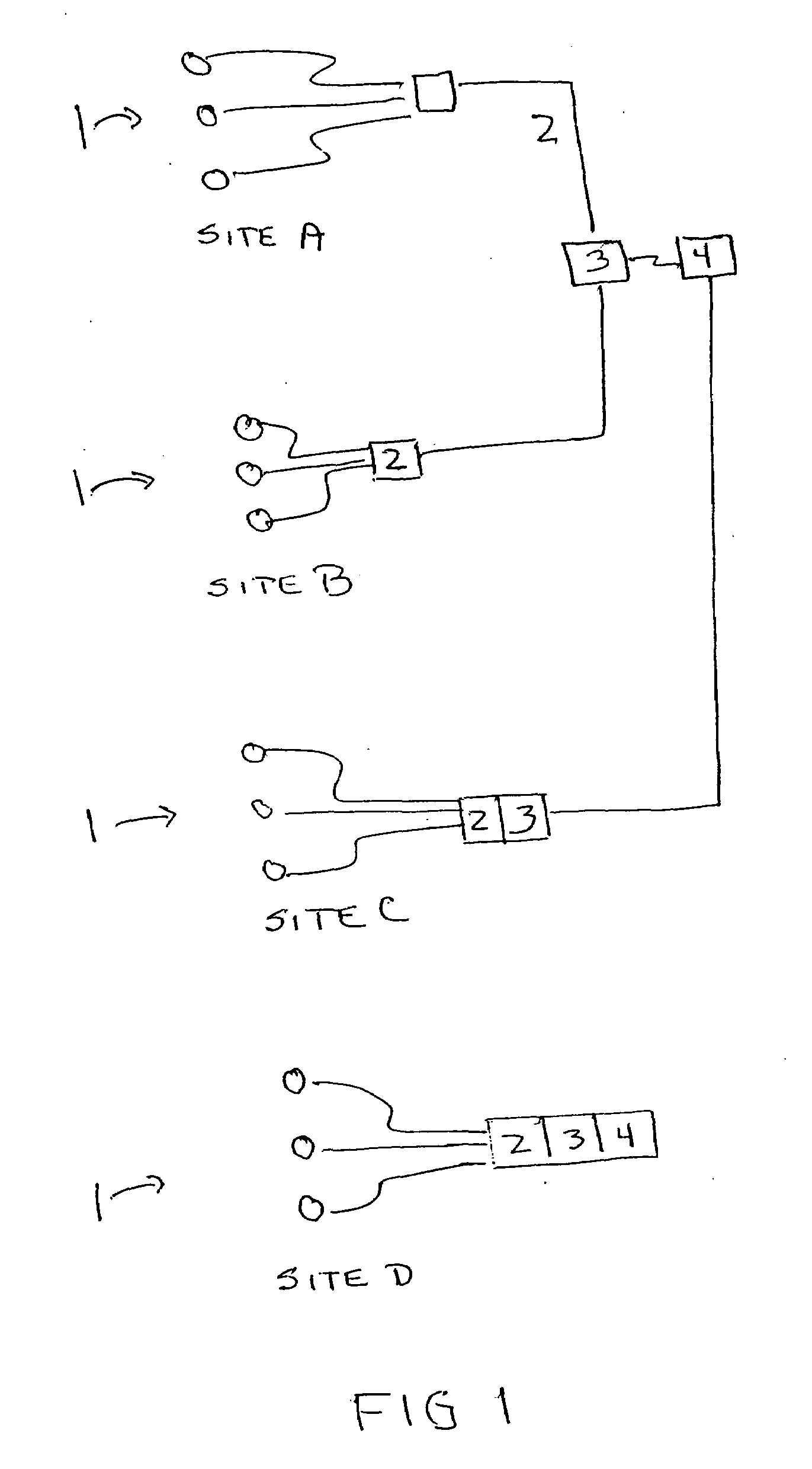

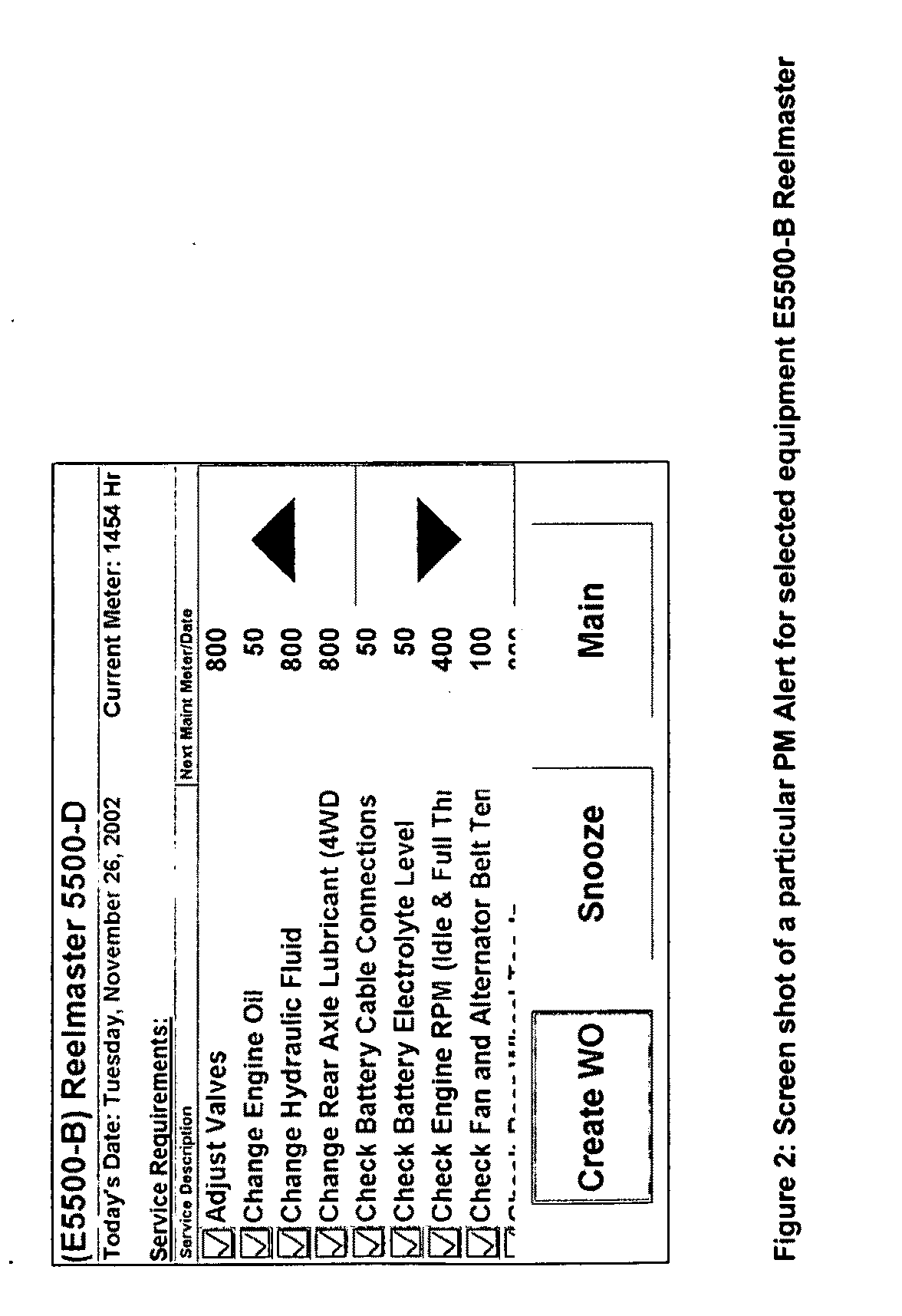

[0045]The system has four aspects: host computer system and software; the transponders and / or other field input stations; the response or other user terminals; and the connecting network (Internet or intranet). The system will be described in an application environment of maintenance of golf course mechanized equipment. As used herein, “vehicle” or “mechanized equipment” is a powered machine (internally powered or externally powered, such as power provided by the PTO of a tractor) which has routine preventative maintenance requirements specified by the manufacturer or another based upon some measure of machine utilization, such as hours of use, mileage accrued, the passage of time, or some other measure reflection use. The system can be physically configured to accommodate a variety of installations. Several configurations are shown in FIG. 1, which shows four physically separated golf course sites A, B, C, and D with each site having a number of vehicles to be monitored for routine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com