Gas/solid phase reaction

a solid phase reaction and gas technology, applied in chemical/physical/physical-chemical processes, chemical apparatus and processes, energy-based chemical/physical/physical-chemical processes, etc., can solve the problem of the enormous influence of the cost of solar current on hsub>2 /sub>production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

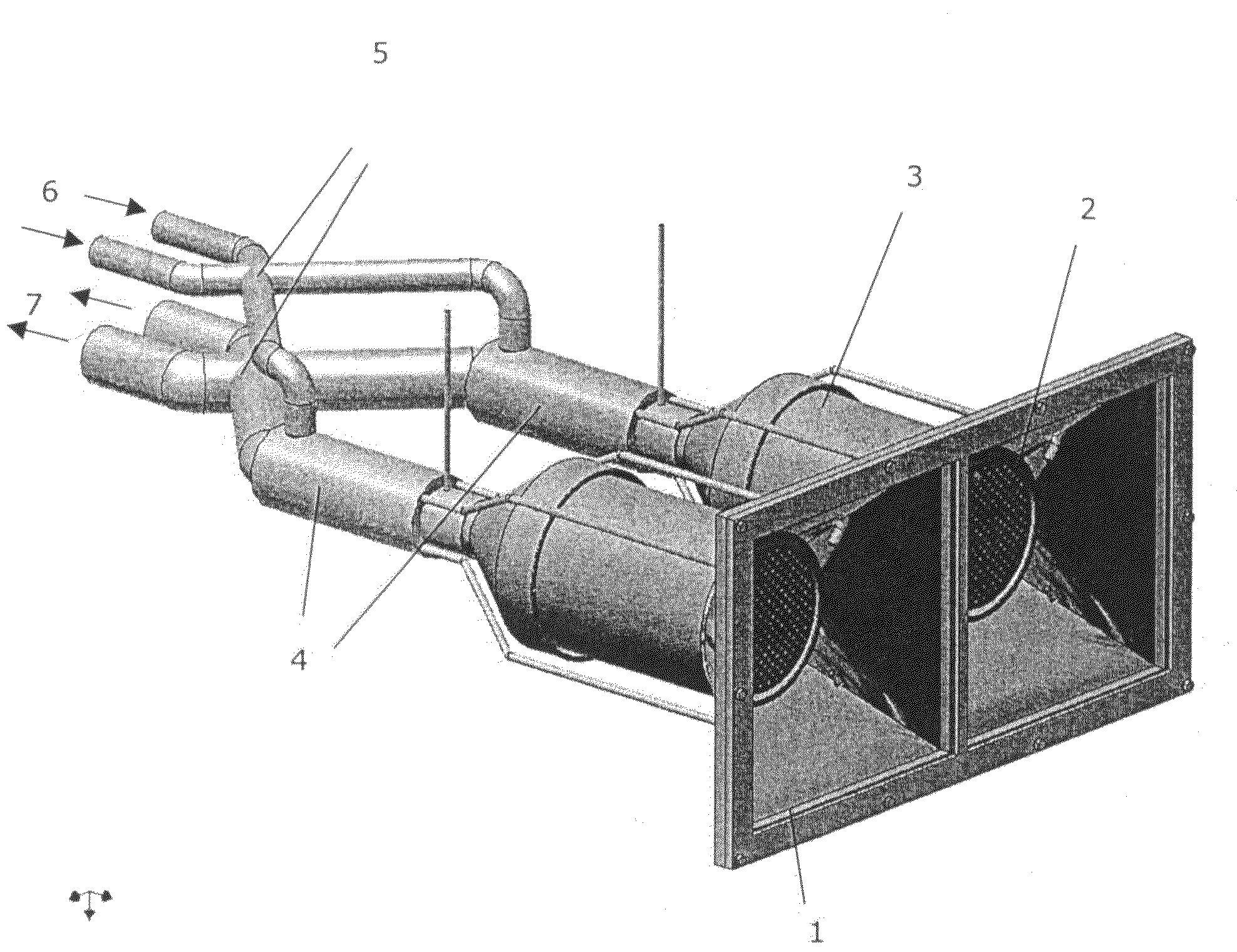

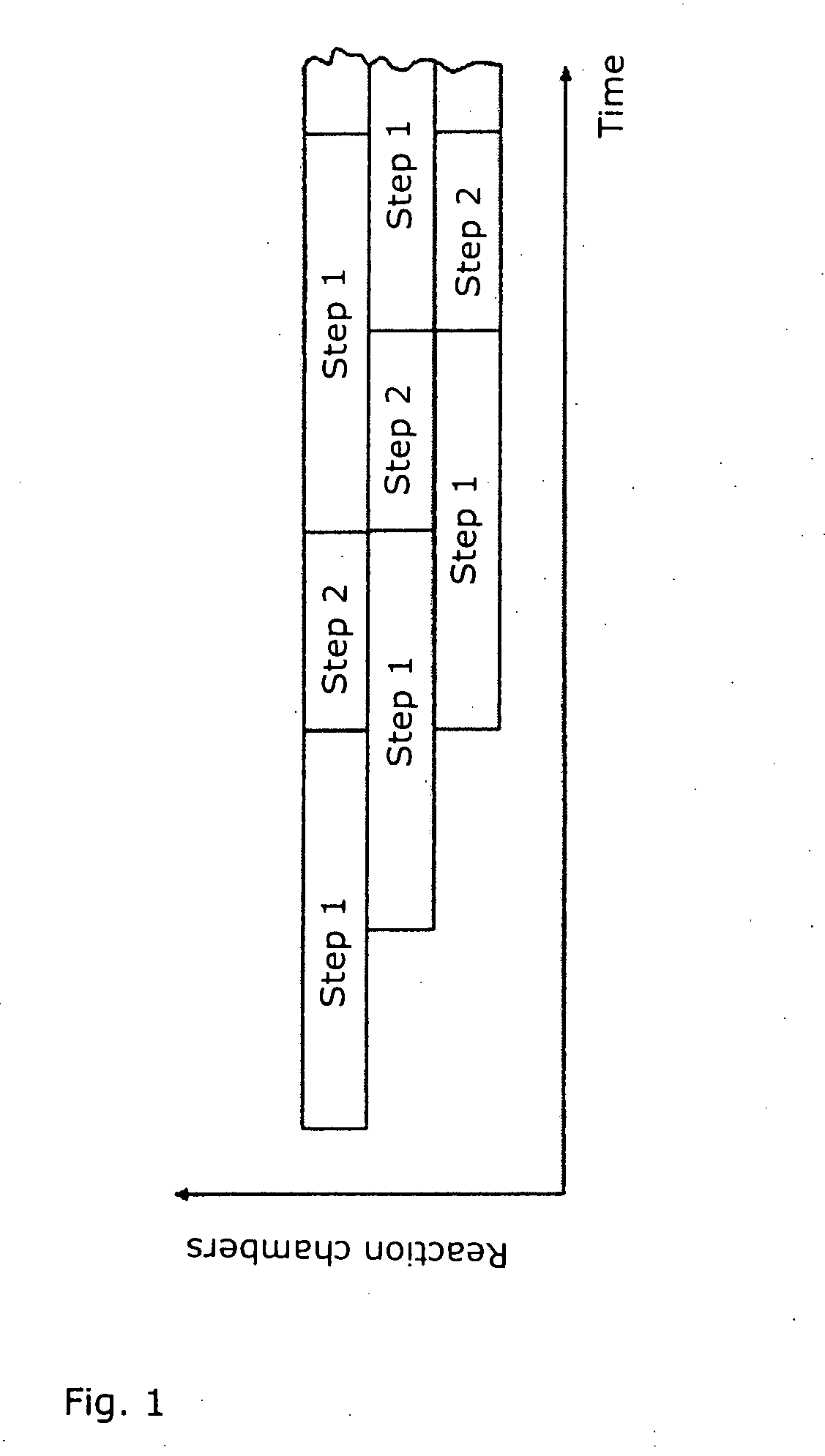

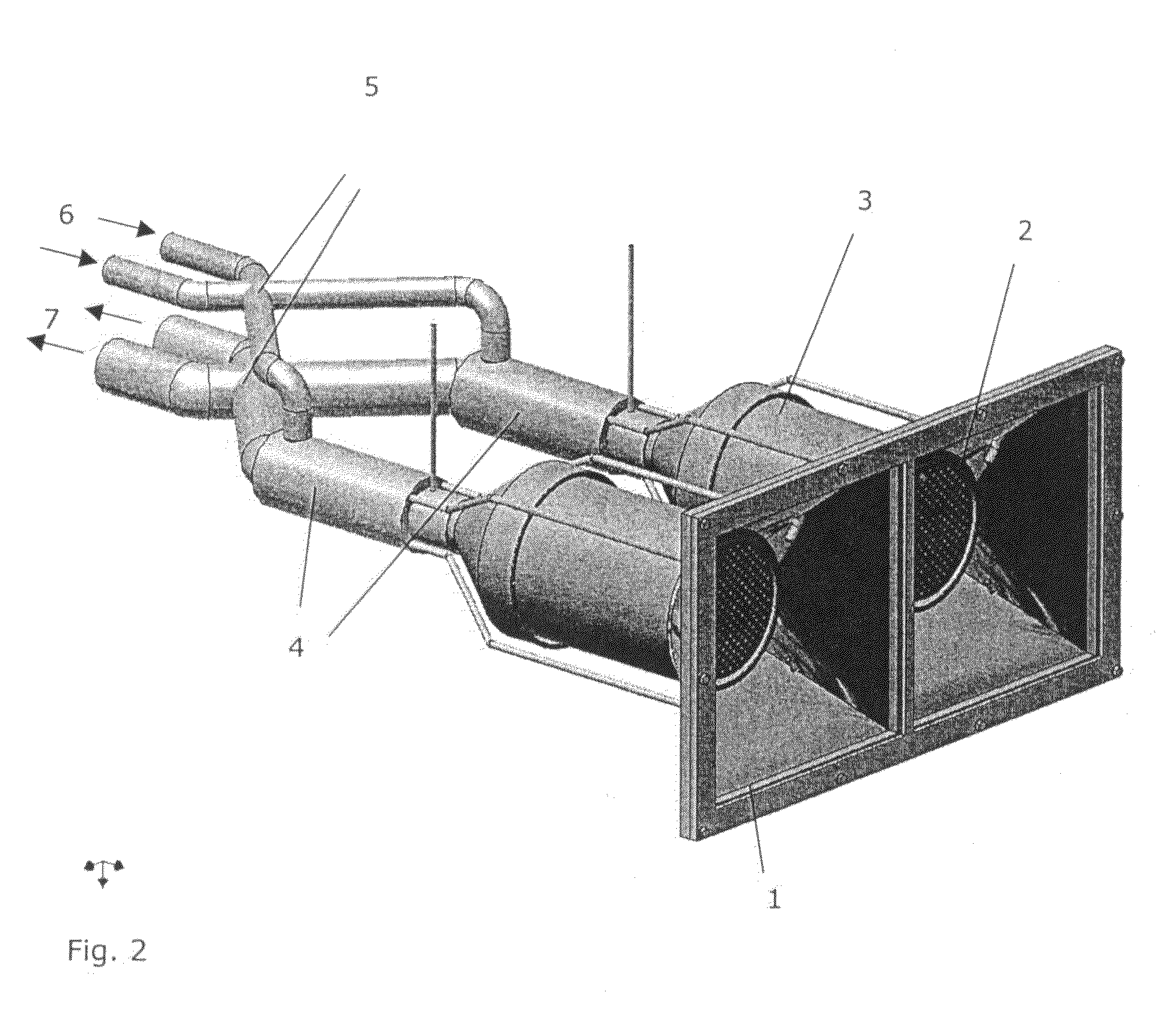

[0023]In the process according to the invention, throughout the reaction time of a first sequential step of a chemical reaction in a first reaction chamber, a second sequential reaction step other than said first sequential reaction step proceeds at least one time in a second reaction chamber, which is different from the first. Thereby, it is achieved that the final product can be provided by the process at any time and the reaction chambers are utilized optimally.

[0024]Since the different sequential reaction steps can have a different reaction time, for optimally utilizing the capacity of the reaction chambers, advantageously:

a) the energy input in the reaction chambers can be selected differently to adjust the reaction rates;

b) the mass flow of the reactants can be adjusted; and / or

c) the number of reaction chambers can be adjusted in accordance with the reaction times in which the reactions proceed in a corresponding time-shifted mode.

[0025]The latter variant is further illustrate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com