Inspection method for semiconductor wafer for reviewing defects

a technology of semiconductor wafers and defects, applied in the direction of material analysis, instruments, and wave/particle radiation, can solve the problems of poor adhesive electrical defects in some cases, and film easy to be easily peeled off, so as to effectively observe the edge of the wafer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028]An embodiment of the present invention is described below by referring to the accompanying drawings.

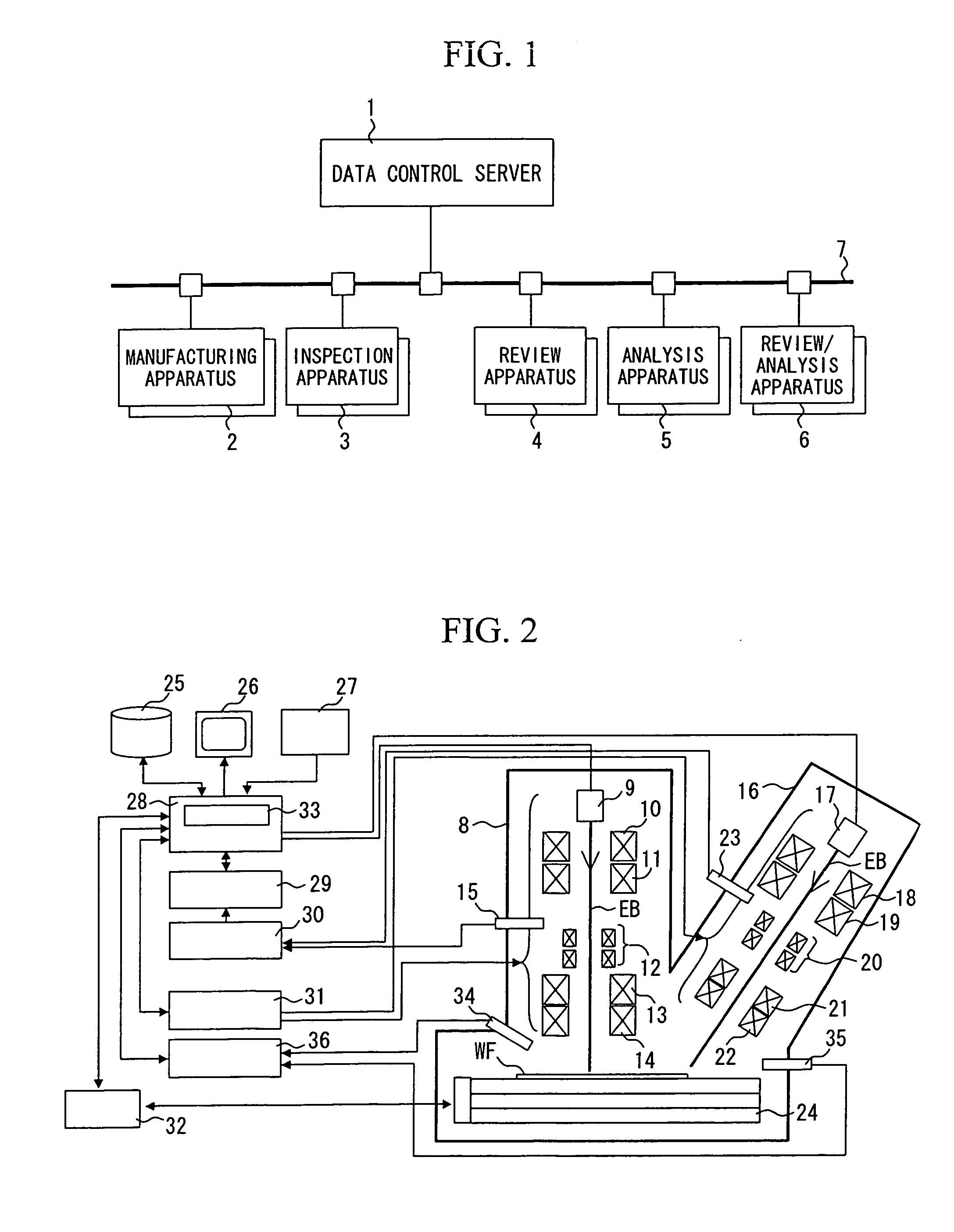

[0029]By using FIG. 1, descriptions will be given, as a specific example, of each of apparatuses on a wafer manufacturing line and a connection configuration thereof. In FIG. 1, reference numeral 1 denotes a data control server; reference numeral 2, a semiconductor manufacturing apparatus; reference numeral 3, an inspection apparatus; reference numeral 4, a review apparatus; reference numeral 5, an analysis apparatus; reference numeral 6, a review / analysis apparatus; and reference numeral 7, a network. As shown in FIG. 1, the manufacturing line has a configuration in which the semiconductor wafer manufacturing apparatus 2, the inspection apparatus 3, the review apparatus 4, the analysis apparatus 5 and the review / analysis apparatus 6 are connected to one another via the data control server 1 and the network 7.

[0030]The manufacturing apparatus 2 has a function as a lithography ma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| semiconductor wafer inspection | aaaaa | aaaaa |

| defect position | aaaaa | aaaaa |

| electron beam optical system | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com