Semiconductor device and method of manufacture thereof

a semiconductor and semiconductor technology, applied in the direction of ion implantation coating, crystal growth process, recording by magnetic means, etc., can solve the problems of unacceptable stresses between materials affecting the device, limiting the bulk crystal material that can be grown on any given substrate, and generally not being able to provide cadmium telluride crystal material, etc., to achieve the desired crystal material more quickly, increase the consistency, and accelerate the growth rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

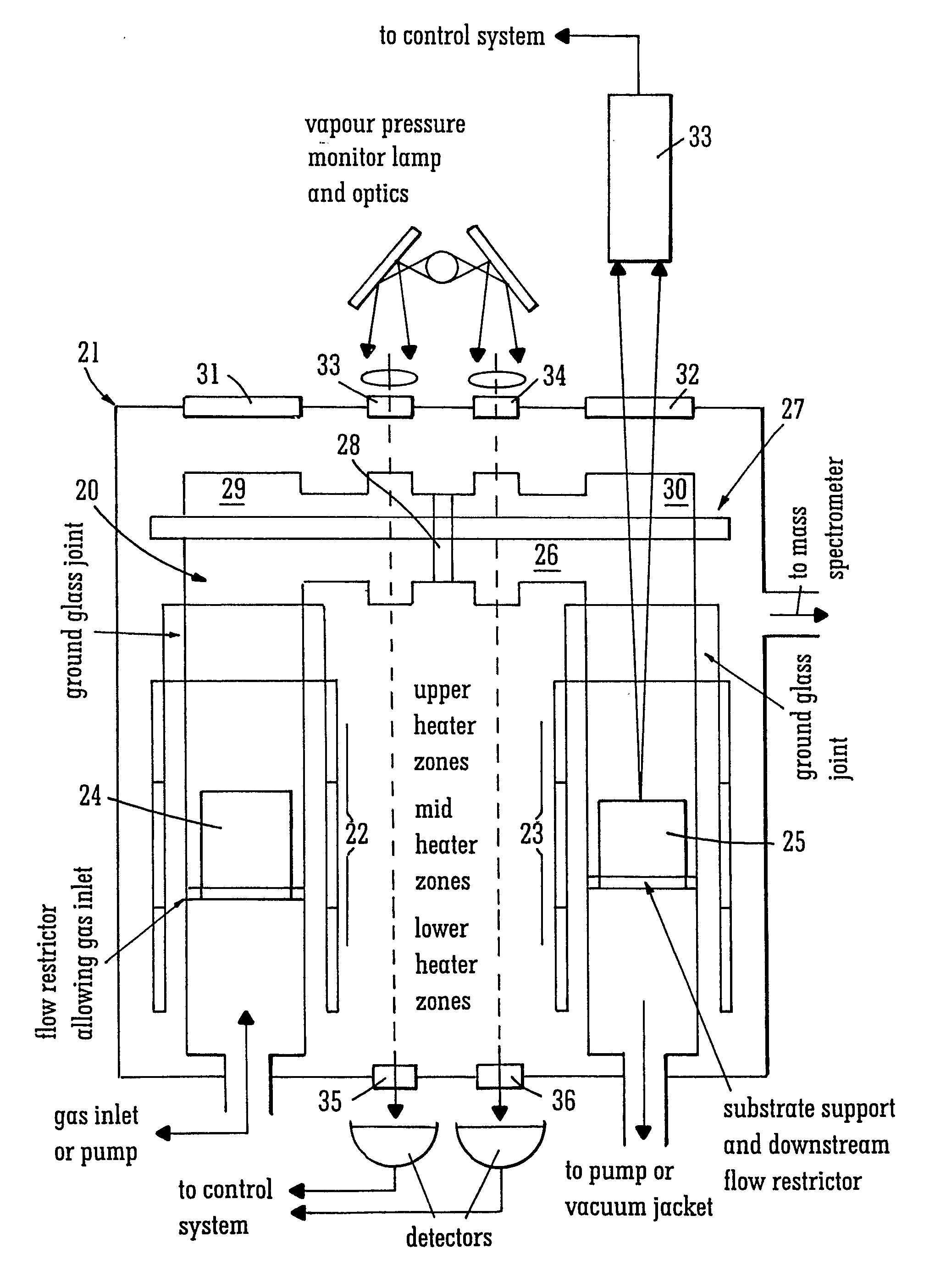

[0034]A preferred apparatus for the formation of a structure according to the present invention is shown in FIG. 1. The apparatus is suitable for forming bulk single crystal materials. Generally bulk crystal materials will have a thickness of at least 500 microns.

[0035]The apparatus comprises an evacuated U-tube in the form of a quartz envelope 20 encased in a vacuum jacket 21. Two separate three zone vertical tubular furnaces are provided 22, 23 for the source 24 and the sink zone 25 respectively. The source and sink zones are connected by an optically heated horizontal crossmember 27 forming a passage 26. A flow restrictor 28 is provided in the passage 26. The passage comprises two separate points of deviation—in each case at an angle of 90°—providing respective junctions between diverging passages for in-situ monitoring and vapour transport from the source to the sink zone. Windows allowing optical access to source and sink respectively are provided. The temperature of the surfac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com