Method of preparing aseptic packaged cooked rice with black bean in aseptic packing system

a technology of aseptic packaging and cooked rice, which is applied in the directions of packaging sterilisation, transportation and packaging, food preparation, etc., can solve the problems of not being able to achieve the effect of improving flavor, nutrition and taste, and not being easy to apply beans to aseptic treatmen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

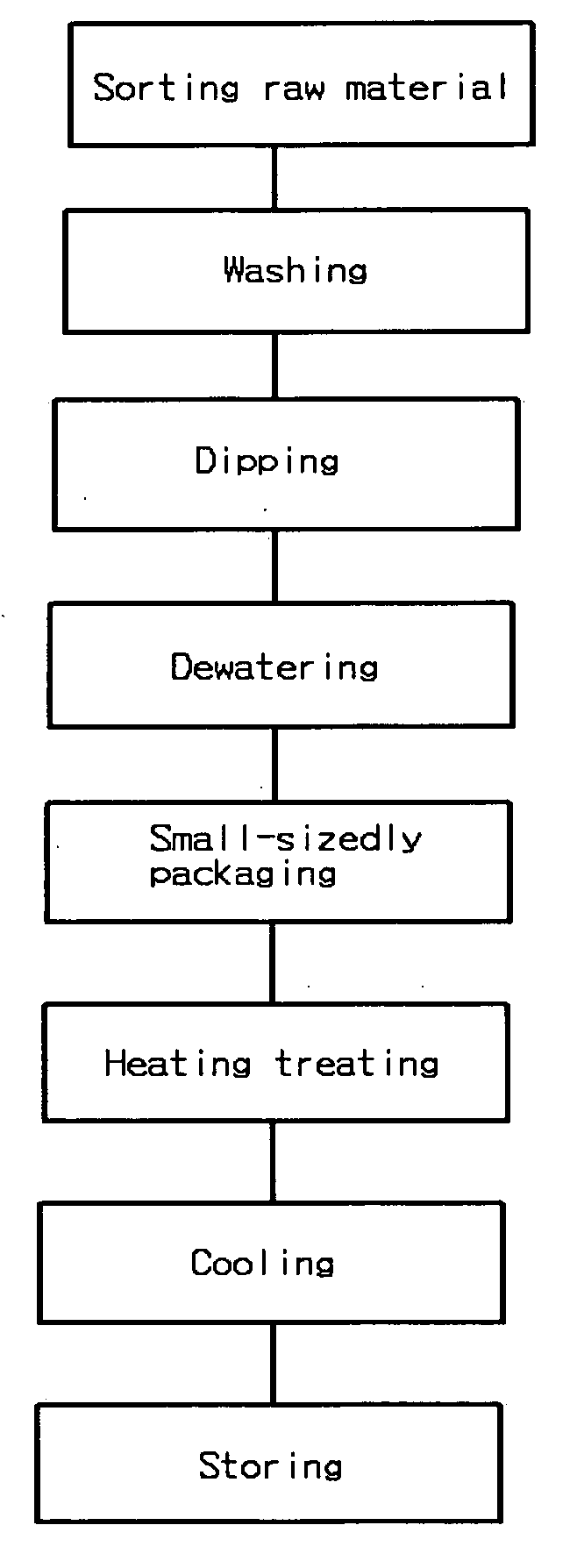

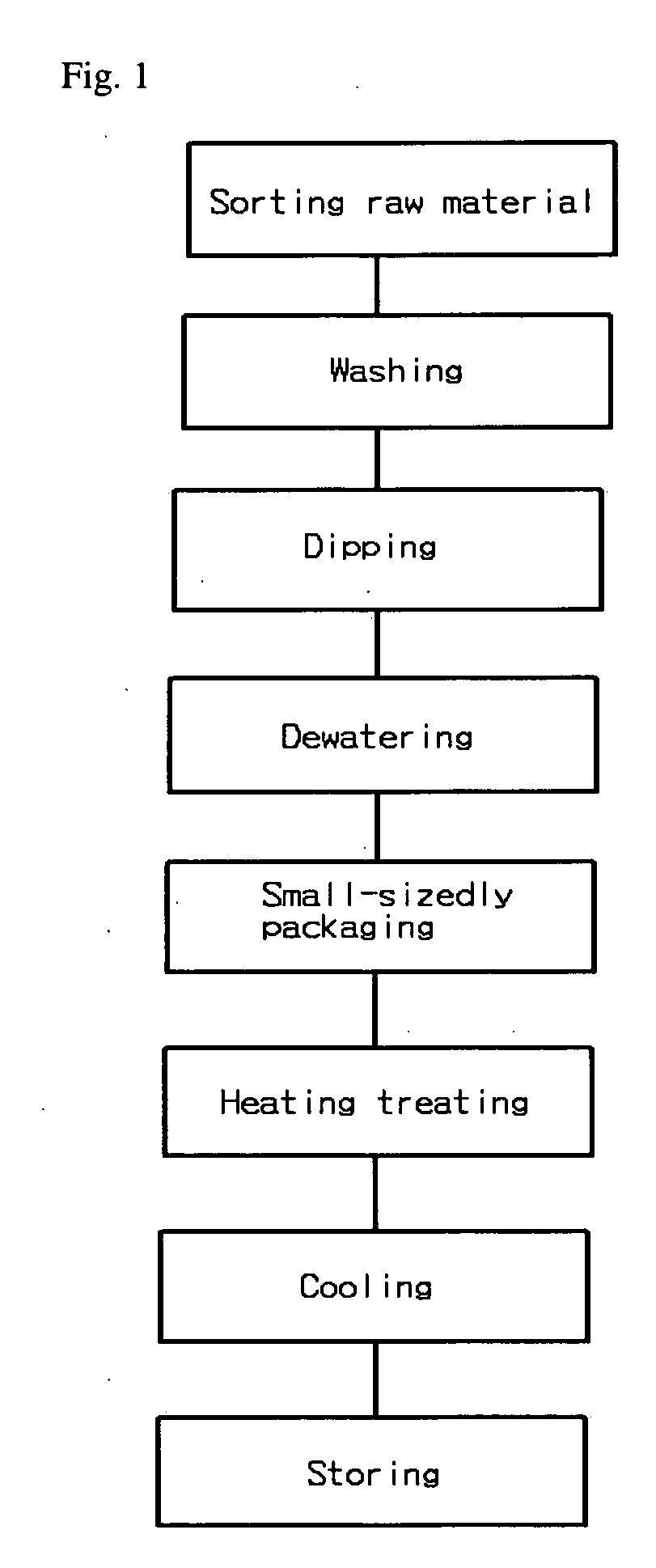

[0027]A microorganism level was verified in each step by dipping black beans of 4.0 mm to 5.6 mm obtained through a size sorting operation into water for one hour to four hours, small-sized packing a predetermined amount of black beans, and heat-treating it for 20 to 50 minutes at 121° C.

example 2

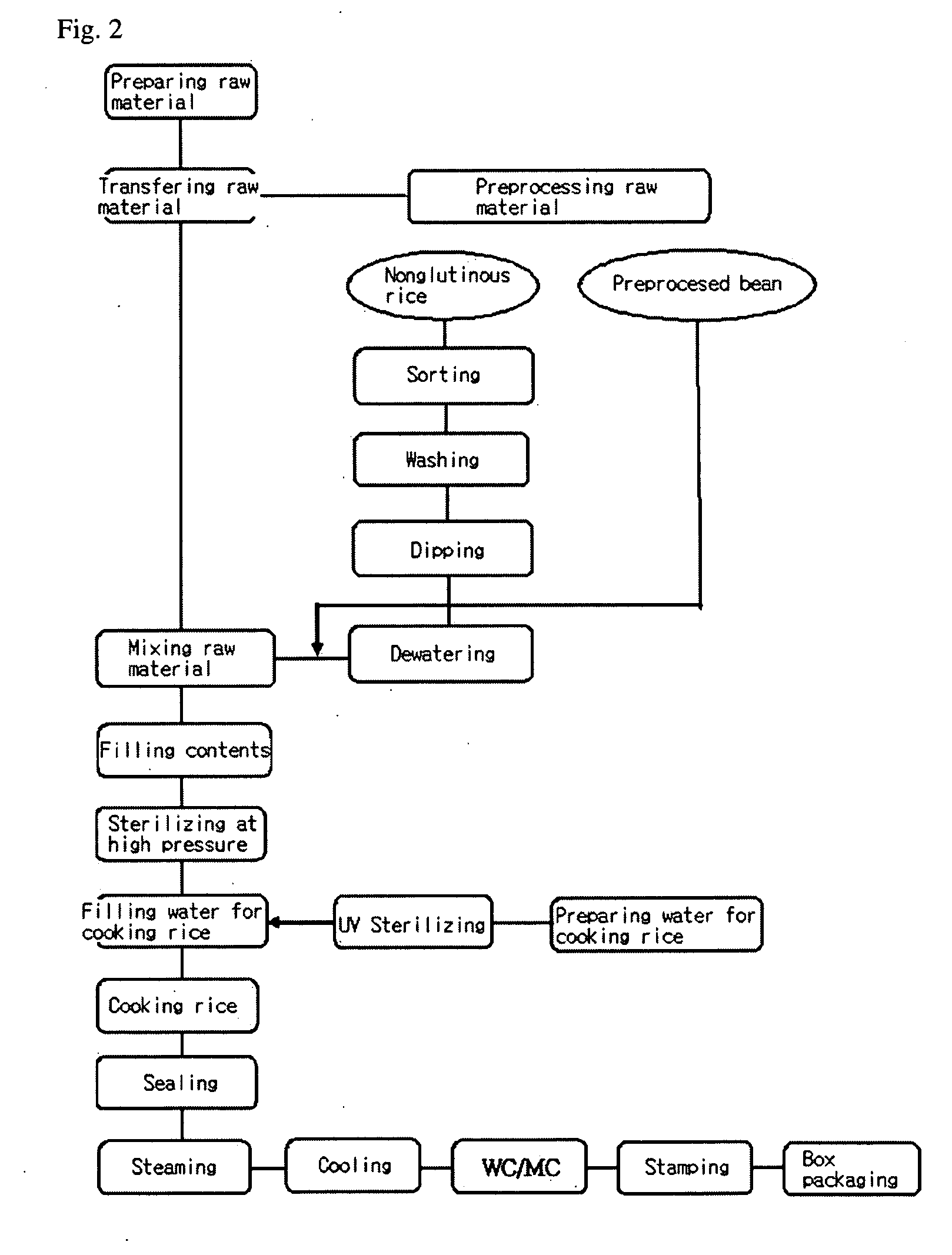

[0028]After the moisture of beans in optimal conditions processed according to the conditions of the Example 1 and dipped raw material rice was removed, the beans and the dipped raw material rice were mixed and were contained in a heat-resistant container, and were then put into a high temperature / high pressure sterilization apparatus. Thereafter, the high temperature / high pressure sterilization apparatus is sealed and high pressure steam was then injected into the high temperature / high pressure sterilization apparatus to sterilize the mixture of the beans and the dipped raw material rice for 8.5 seconds at a temperature of 140 to 143° C. The high temperature steam sterilization process was repeated seven times. After the high temperature steam sterilization process was completed, rice was cooked for 35 minutes by using the UV sterilized purified water as water for cooked rice for every the sterilized container and constantly maintaining the steam temperature of a rice cooking machi...

experimental example 1

[0029]The processing conditions between the beans prepared by means of the optima preprocessing method of beans used in Korean Patent Laid-Open Publication No. 2000-0019145 of the prior art and the beans prepared by means of the preprocessed beans according to the Example 1 are compared (table 1). In order to confirm the quality of processed bean, and the quality of cooked rice and the safety of microorganisms when preparing the aseptic cooked rice, a bacterial activity test was performed to confirm whether a long-term distribution can be achieved. Also, the aseptic cooked rice was mass-produced using production line for aseptic cooked rice so that the problems in processes of two processed groups are compared.

TABLE 1Comparison processingconditionsPrior artPresent inventionSpecies of beanSoybean (selitae)Redbean (bean rhynchosianolubilis)Bean sorting processSorting foreign materialSorting foreign materialSize sorting (4.0 mm~5.6 mm)Size of bean after being12.69 × 7.78 × 5.948.77 × 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com