Method of plating metal onto titanium

a technology of titanium and metal alloy, applied in the field of metal or metal alloy electroplating on titanium, can solve the problems of poor abrasion resistance, poor tribological properties, and little use of titanium and titanium alloys in mechanical engineering applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

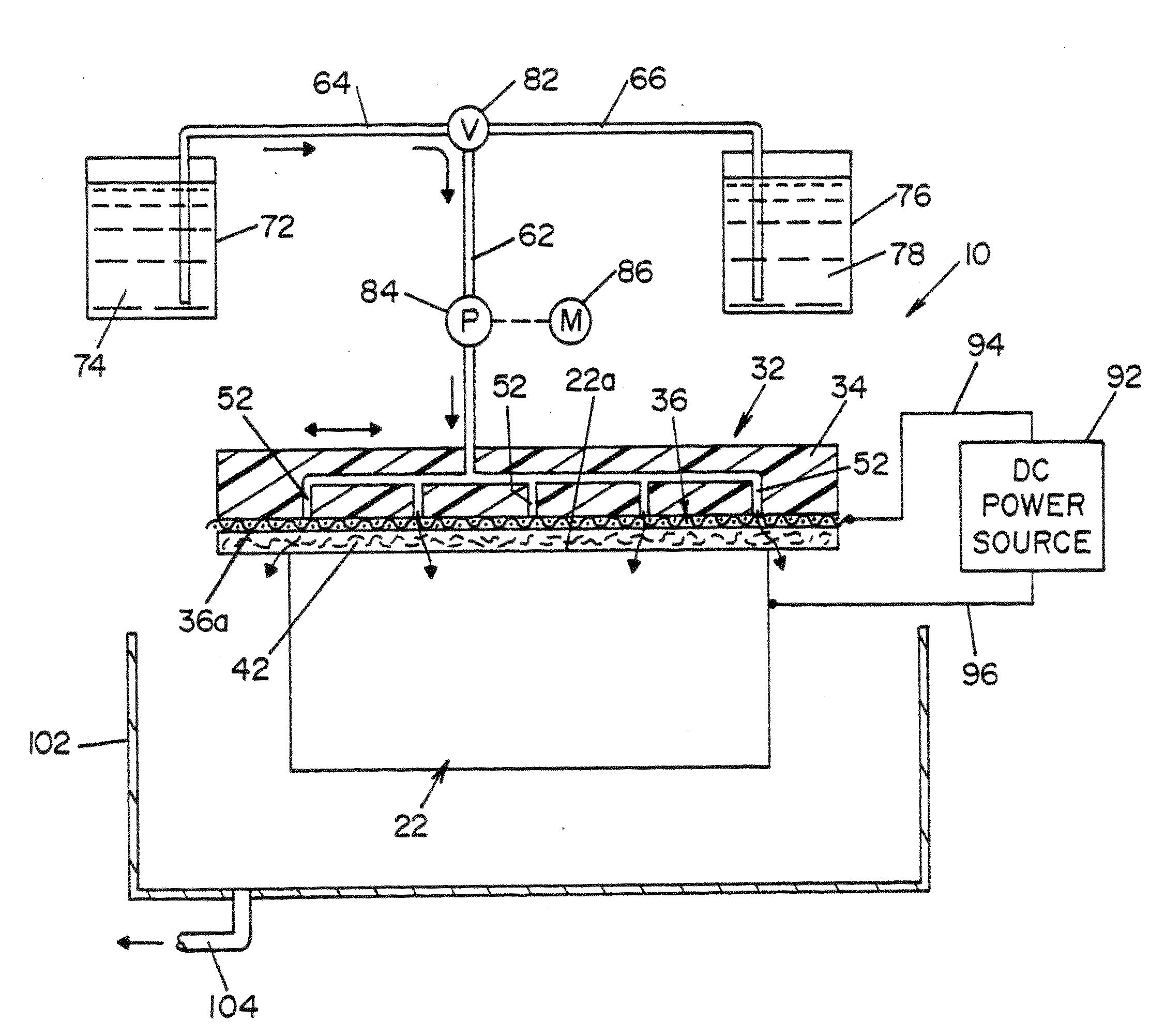

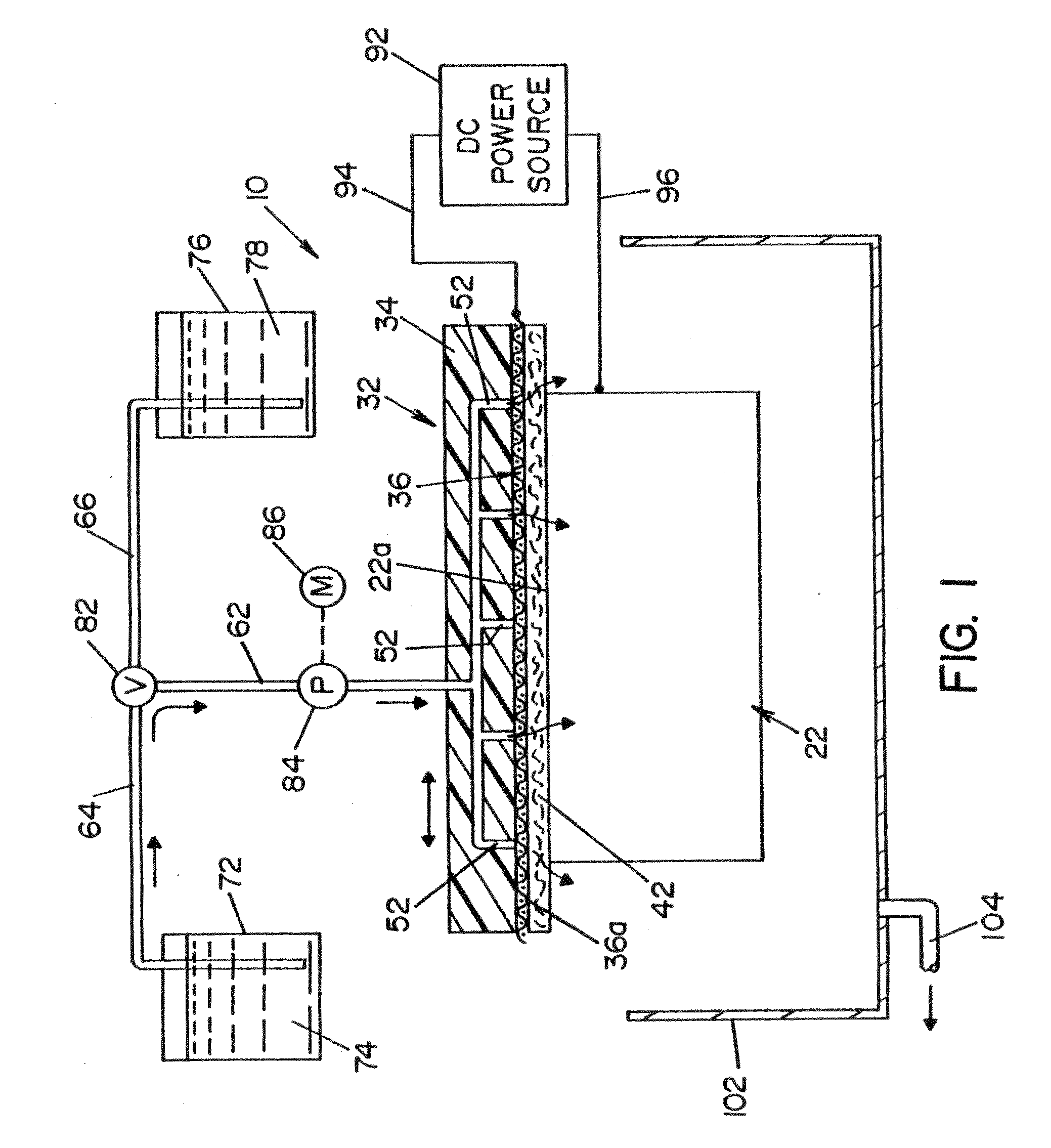

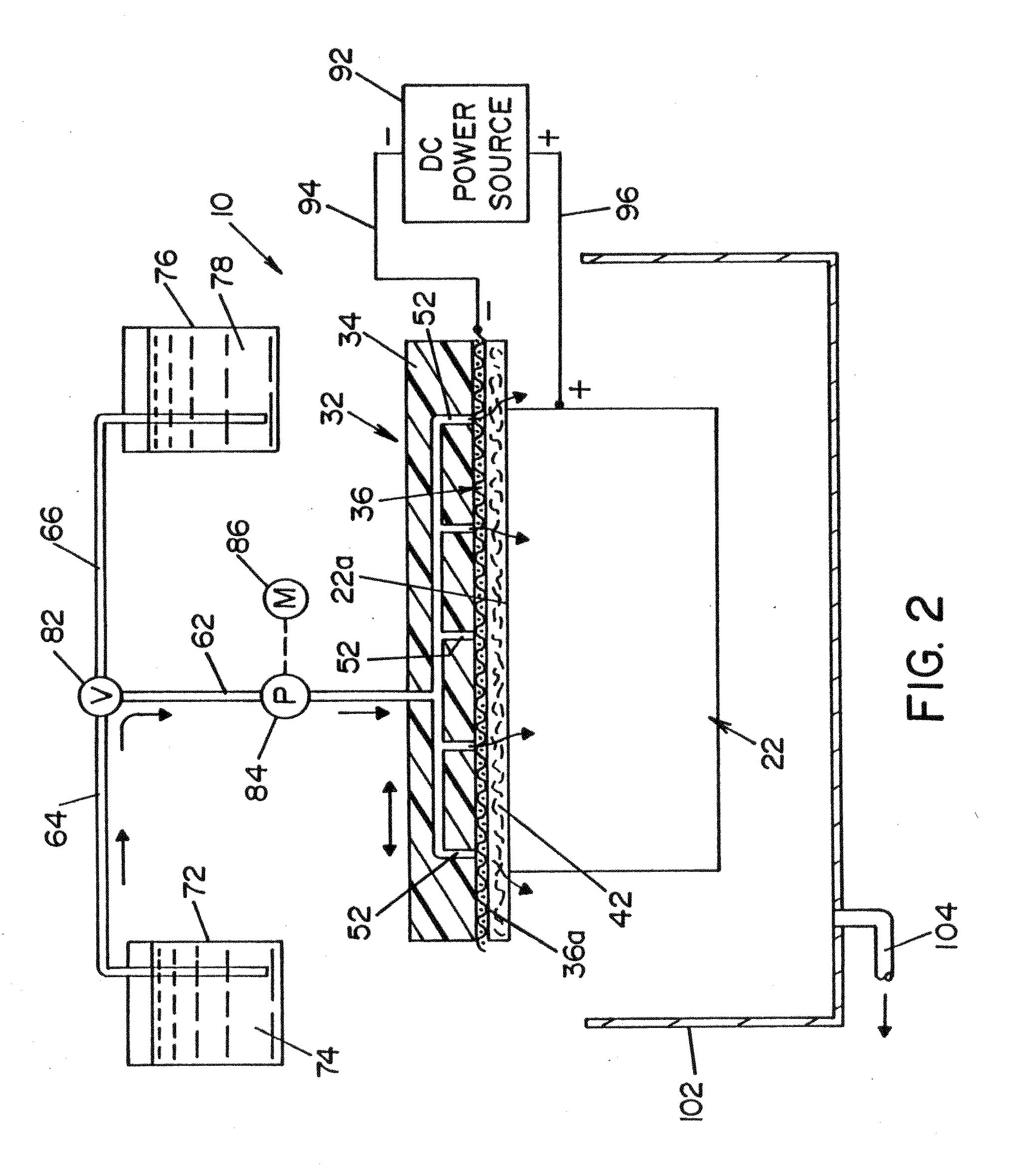

Image

Examples

example i

[0049]Using the foregoing process, nickel is brush plated onto a sheet of 6-4 Titanium. The titanium is kept under an electrical potential at all times following the initial surface cleaning step. The plated area is 100% covered by the brush pad 42, and the electrical potential is rapidly switched from anodic to cathodic. No rinsing occurs between steps, and the etching and plating solutions are not reused.

[0050]The process for producing nickel coatings on 6-4 Titanium is as follows:

StepOperationMaterialConditions1Abrading stepRed Scotch BriteWet with etching solution2Etching stepEtching solutionWet with etching solution,14 V anodic, 10 seconds3Activation stepEtching solutionWet with etching solution,4-8 V cathodic, 1 minute4Plating stepPlating solutionWet with plating solution,8-18 V cathodic, 0.078A * hr / cm2

[0051]The etching solution is comprised of 10% NaCl, 7% HCl, 1% Ni salts, 0.3% citric acid by weight. The plating solution is comprised of an acid nickel sulfate solution sold ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com