High absorbency lyocell fibers and method for producing same

a technology of lyocell fibers and absorbent materials, which is applied in the field of improving the absorbency characteristics of lyocell fibers, can solve the problems of not being able to demonstrate appreciable effects of treatment on the absorbency characteristics of cellulosic materials, and not being able to use lyocell in any significant quantity for these articles, so as to achieve the effect of increasing the absorbency of the material

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

examples

[0032]The techniques utilized in the hydrothermal treatment of the invention, and the improved absorbency characteristics thus obtained, are illustrated in the following examples, wherein all temperatures are given in degrees Celsius and all parts and percentages are by weight, unless otherwise indicated.

examples 1-4

[0033]Laboratory-made tampons having a mass of about 2.5 g were made according to the general teaching of Friese et al., U.S. Pat. No. 6,310,269, the disclosure of which is hereby incorporated by reference. The tampons were then subjected to the Syngyna Test as described in the US Federal Register, Part III, Department of Health and Human Services, Food and Drug Administration (21 CFR §801.430, Apr. 1, 2001). The results are shown in Table 1, below:

TABLE 1SyngynaSyngynaDensityValue forValueSampleDescription(g / cm3)tampon (g)(g / g)Comparative1.5 denier0.3899.923.89Example 1ATENCEL ®Example 1BTreated10.39011.374.441.5 denierTENCEL ®Comparative2.2 denier0.39410.323.97Example 2ATENCEL ®Example 2BTreated10.31910.965.182.2 denierTENCEL ®Comparative3 denier0.40610.564.14Example 3ATENCEL ®Example 3BTreated1 30.40612.364.82denierTENCEL ®Comparative1.5 denier0.399.973.86Example 4ATENCEL ®Example 4BTreated20.3812.394.801.5 denierTENCEL ®1Hydrothermal treatment in boiling water at 90-100° C. for ...

examples 5 and 6

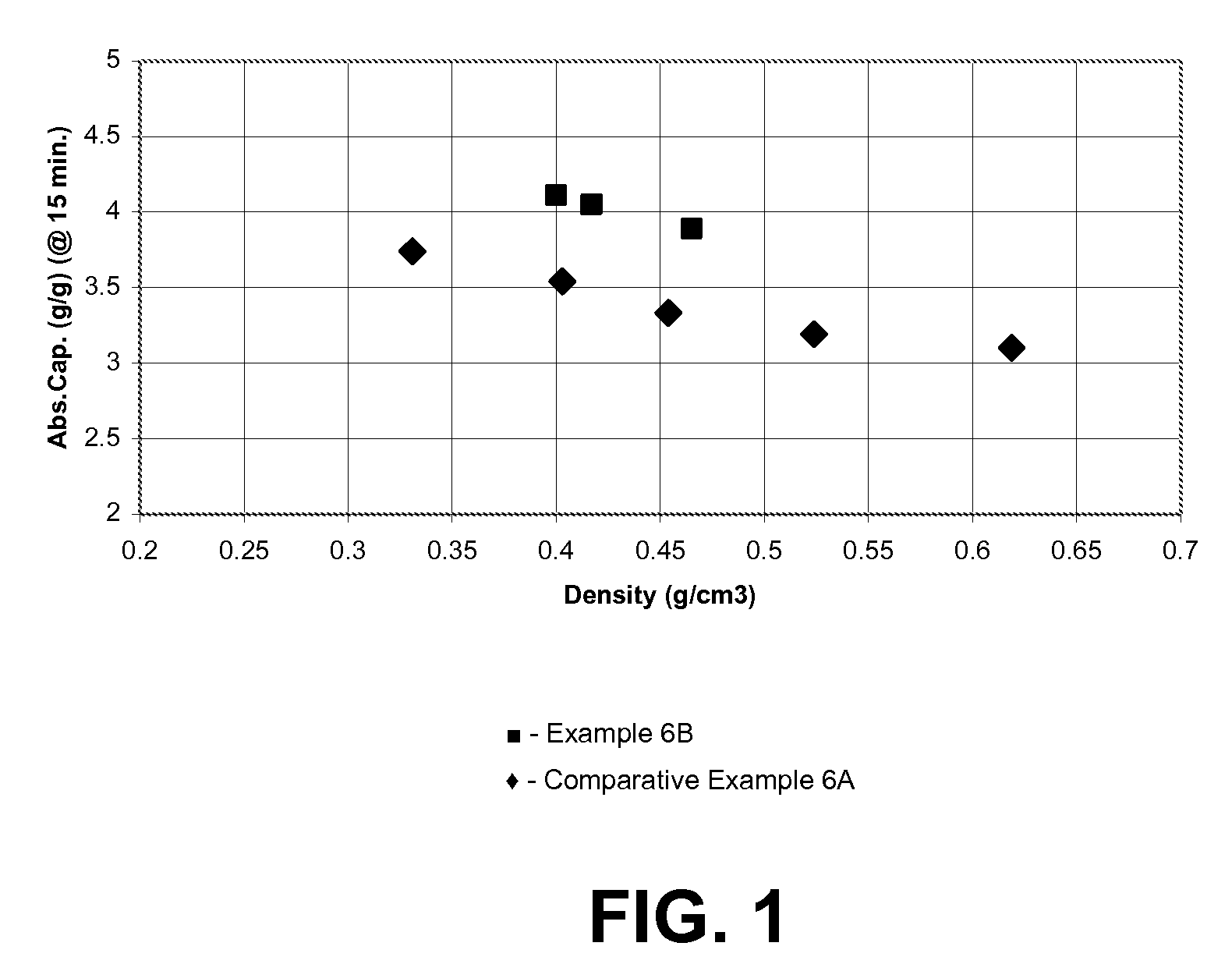

[0035]Compressed fibrous structures can take advantage of the present invention. The improvements can be shown by use of the Plug Test described hereinbelow.

[0036]Plug Test

[0037]The fiber blend is opened via standard fiber opening and carding equipment.

[0038]Sample Preparation Procedure: A fixed amount of fiber blend, of weight 2 grams, is introduced into a stainless steel mold with a cylindrical cavity (of diameter 1 inch). A cylindrical plunger which fits into the cavity is used to compress the fiber mass. A laboratory press is used to apply the necessary pressure.

[0039]After coming out of the mold the plug is left on the bench for about 20-30 minutes to equilibrate to an equilibrated thickness, from which the density of the plug is calculated.

[0040]Plug Absorbency Test: The test sample is the equilibrated plug. The plug is tested in a Gravimetric Absorbency Tester (as described in Pronoy K. Chatterjee and Hien V. Nguyen, “Mechanism of Liquid Flow and Structure Property Relationsh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com