Apparatus for purification of exhaust gas and method for purification of exhaust gas using the same

a technology for purifying apparatuses and exhaust gas, which is applied in the direction of exhaust treatment electric control, physical/chemical process catalysts, and separation processes. it can solve the problems of large amount of sosub>x /sub>emitted, the apparatus for purifying exhaust gas described in documents 1 to 5 is not capable of rapidly shifting the air-fuel ratio of exhaust gas flowing into the catalyst at the downstream side to a lean state, and the production of h2s. , to preven

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

production example 1

Pt / CZ+Ni Catalyst

[0066]A Pt / CZ+Ni catalyst was produced with platinum and nickel supported on a support (CZ support) including a ceria-zirconia solid solution. To be more specific, the CZ support is a solid solution consisting primarily of ceria and zirconia including stabilizing agents, La2O3 and Pr2O3, at 3 mass % and 7 mass %, respectively (ceria content: 60 mass %, zirconia content: 40 mass %), and has a specific surface area of approximately 100 m2 / g. A catalyst slurry was prepared by mixing the CZ support and an alumina sol. After being coated with the catalyst slurry, a honeycomb substrate composed of cordierite was calcined at 500° C. to obtain a support-coated substrate. After provided with platinum through absorption, the support-coated substrate was calcined at 500° C., and then further provided with a nitrate solution of nickel through absorption, to obtain the Pt / CZ+Ni catalyst. The amount of platinum, CZ support, alumina sol, and nickel, included in the obtained cataly...

production example 2

Pt / Cz+Fe Catalyst)

[0067]Except for using a nitrate solution of iron (Fe) in the place of a nitrate solution of nickel in the production example 1, the same process was adopted to obtain a catalyst (Pt / CZ+Fe catalyst) supporting platinum and iron on the CZ support. The amount of platinum, CZ support, alumina sol, and iron, included in the obtained catalyst was 0.03 g per 1 L of catalyst, 150 g per 1 L of catalyst, 20 g per 1 L of catalyst, and 0.05 mol per 1 L of catalyst, respectively.

example 1

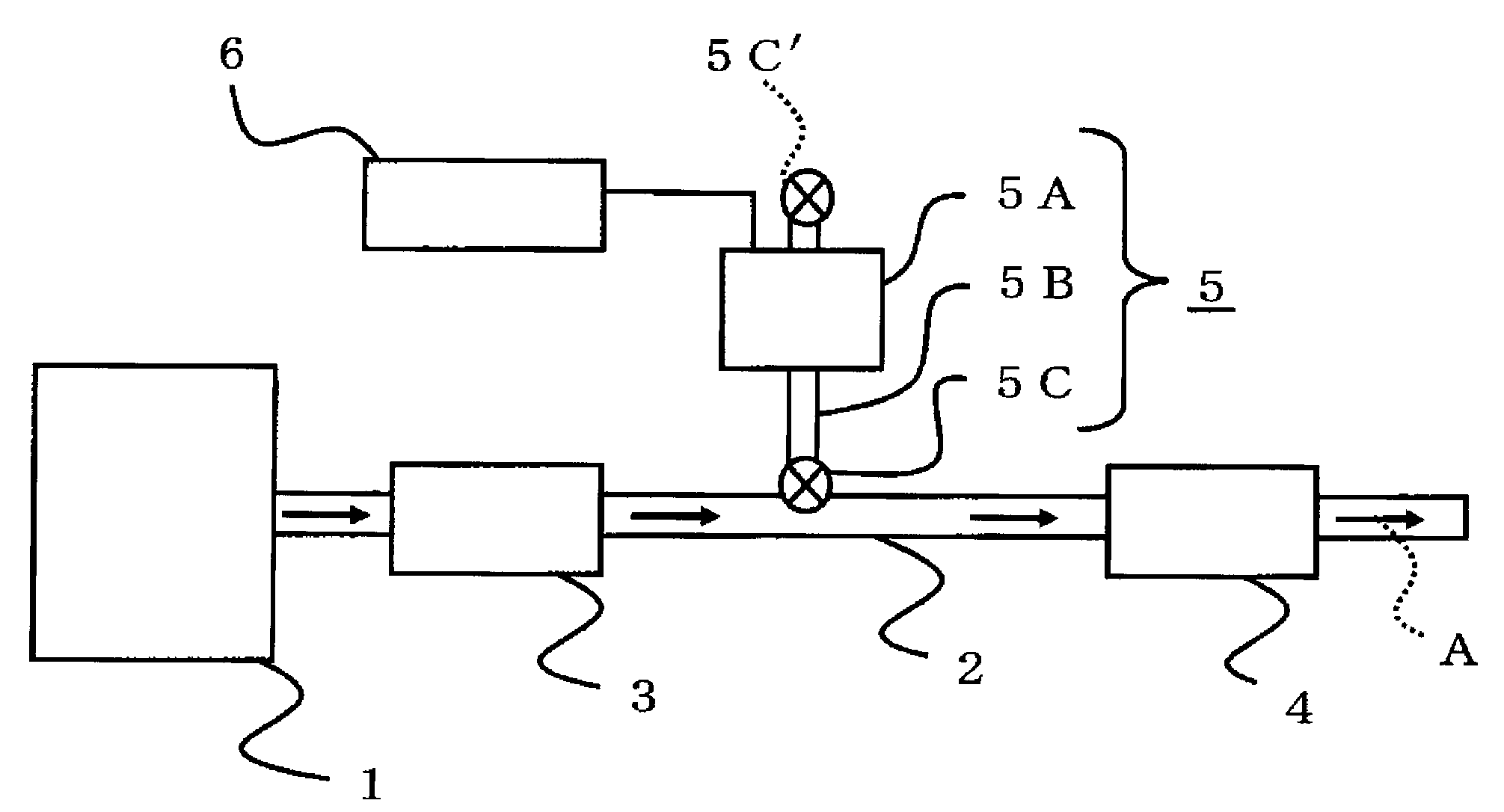

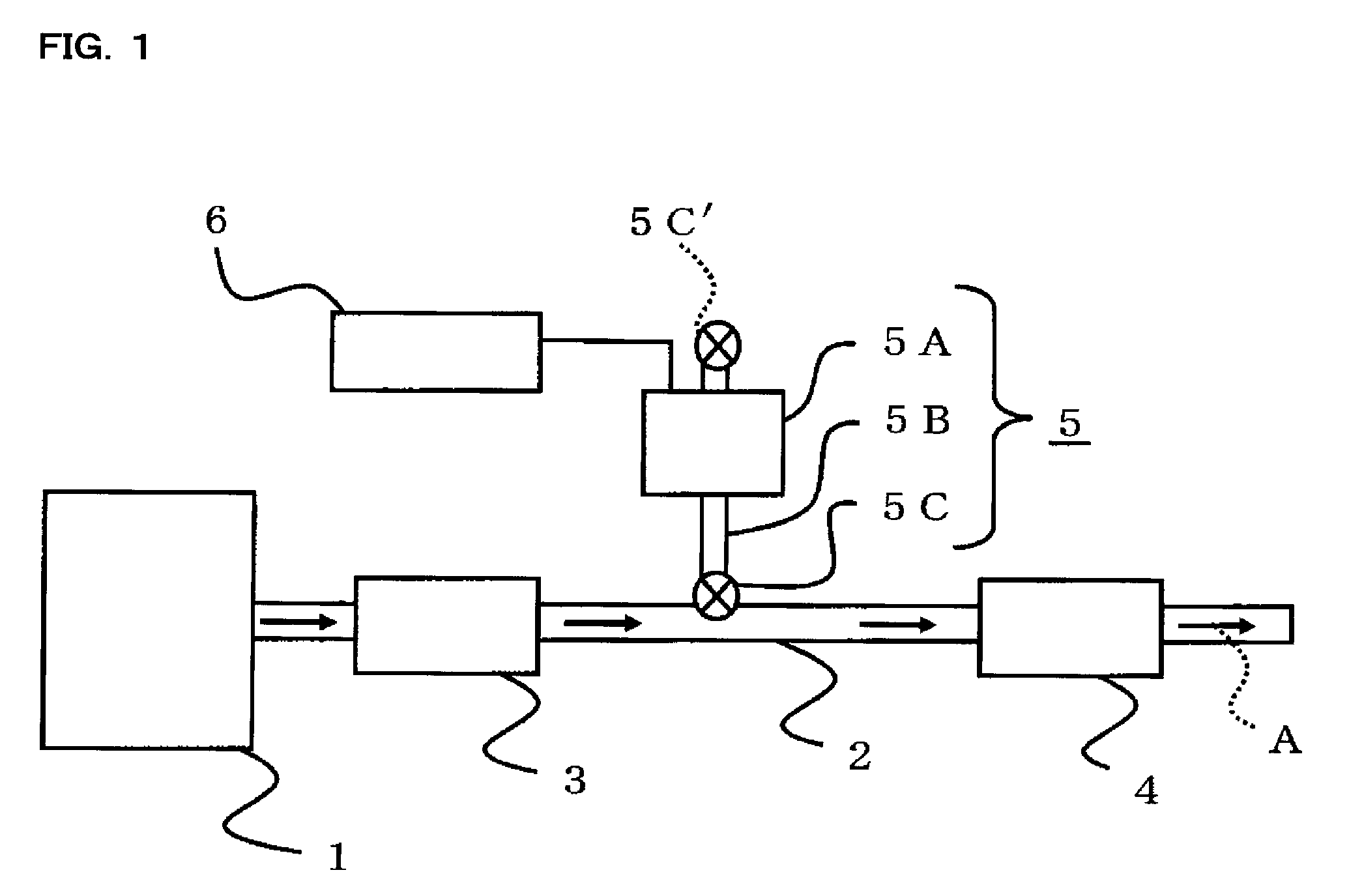

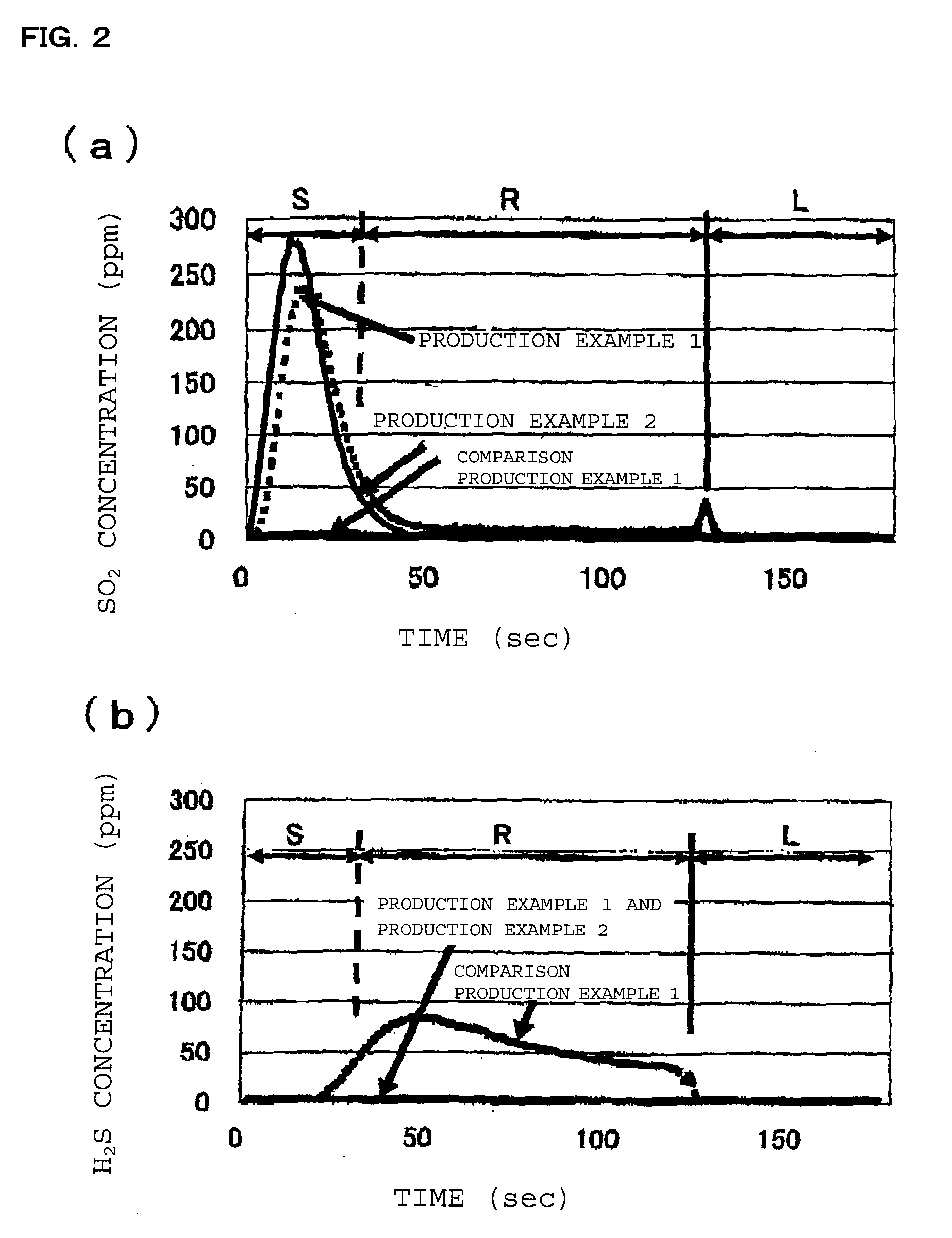

[0074]A model test was conducted in which an apparatus for purification of exhaust gas is provided to an exhaust system of an automobile equipped with a 2.4 L-gasoline engine. The concentrations of H2S and SO2 included in exhaust gas were measured. To be more specific, the apparatus for purification of exhaust gas having the configuration shown in FIG. 1 was adopted, which includes: a commercially-available three-way catalyst (Pt—Rh / (alumina+CZ) catalyst) as the upstream catalyst 3; the Pt / CZ+Fe catalyst obtained in the production example 2 as the downstream catalyst 4; a small-sized pump capable of supplying gas at 30 L / min as the oxidizing gas supply pump 5A; a bimetallic air intake bulb as the air intake bulb 5C; and an ECU as the control means 6. A model test was conducted in which an automobile having the apparatus for purification of exhaust gas attached to the exhaust system of a 2.4 L-gasoline engine was driven on a turntable in the LA #4 mode test of the United States, acce...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Angular velocity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com