Perforated easy opening pouch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

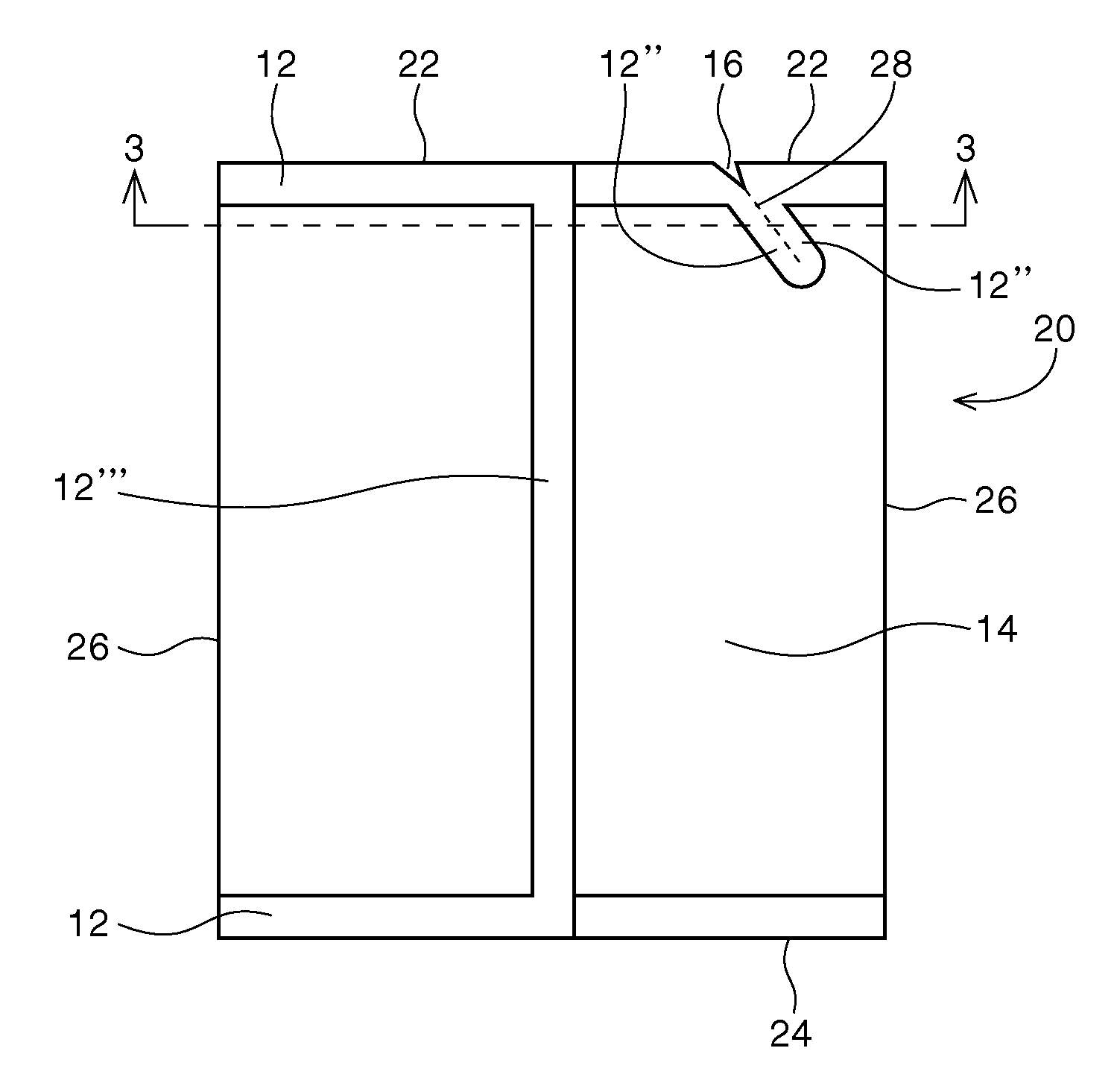

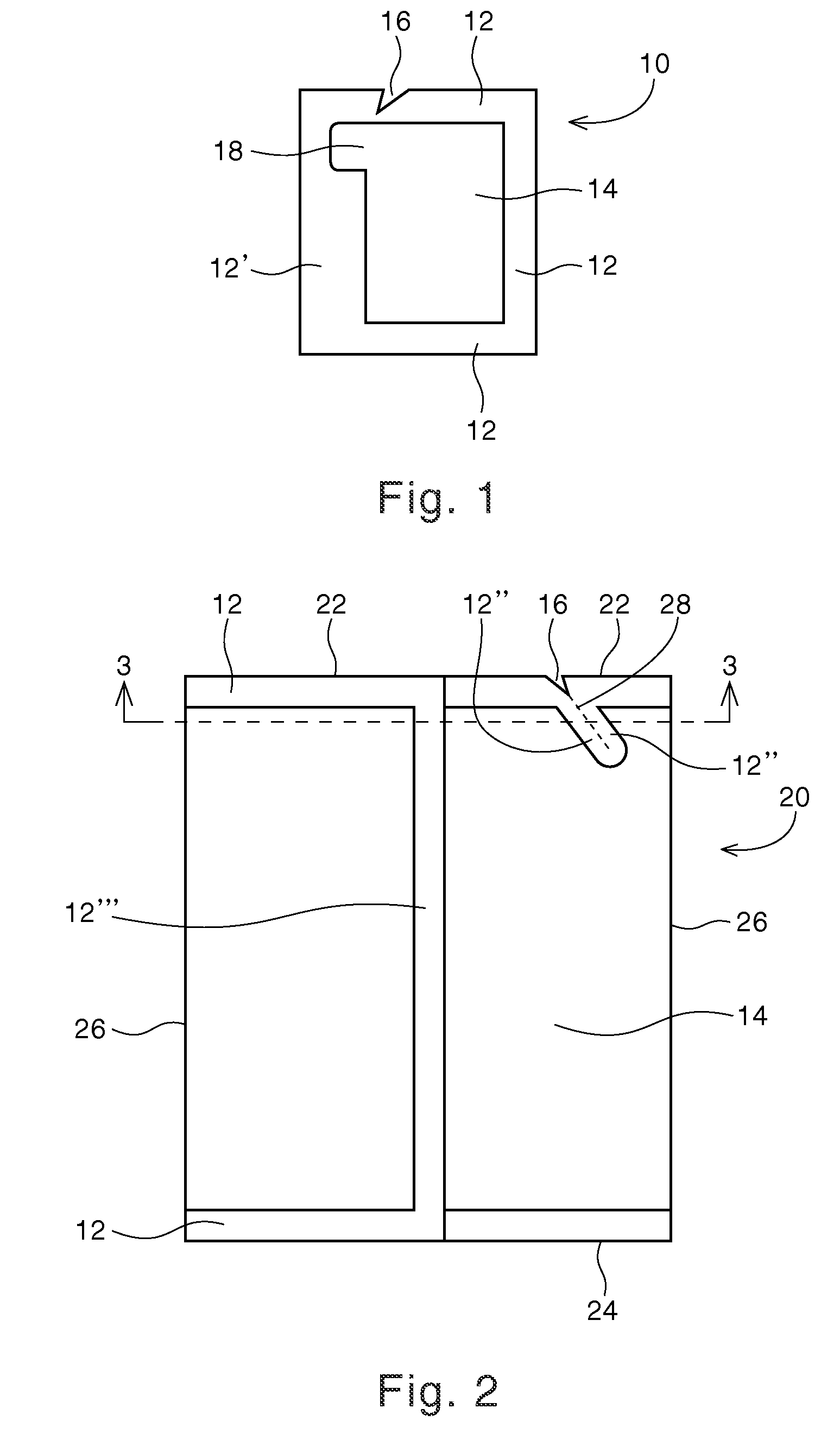

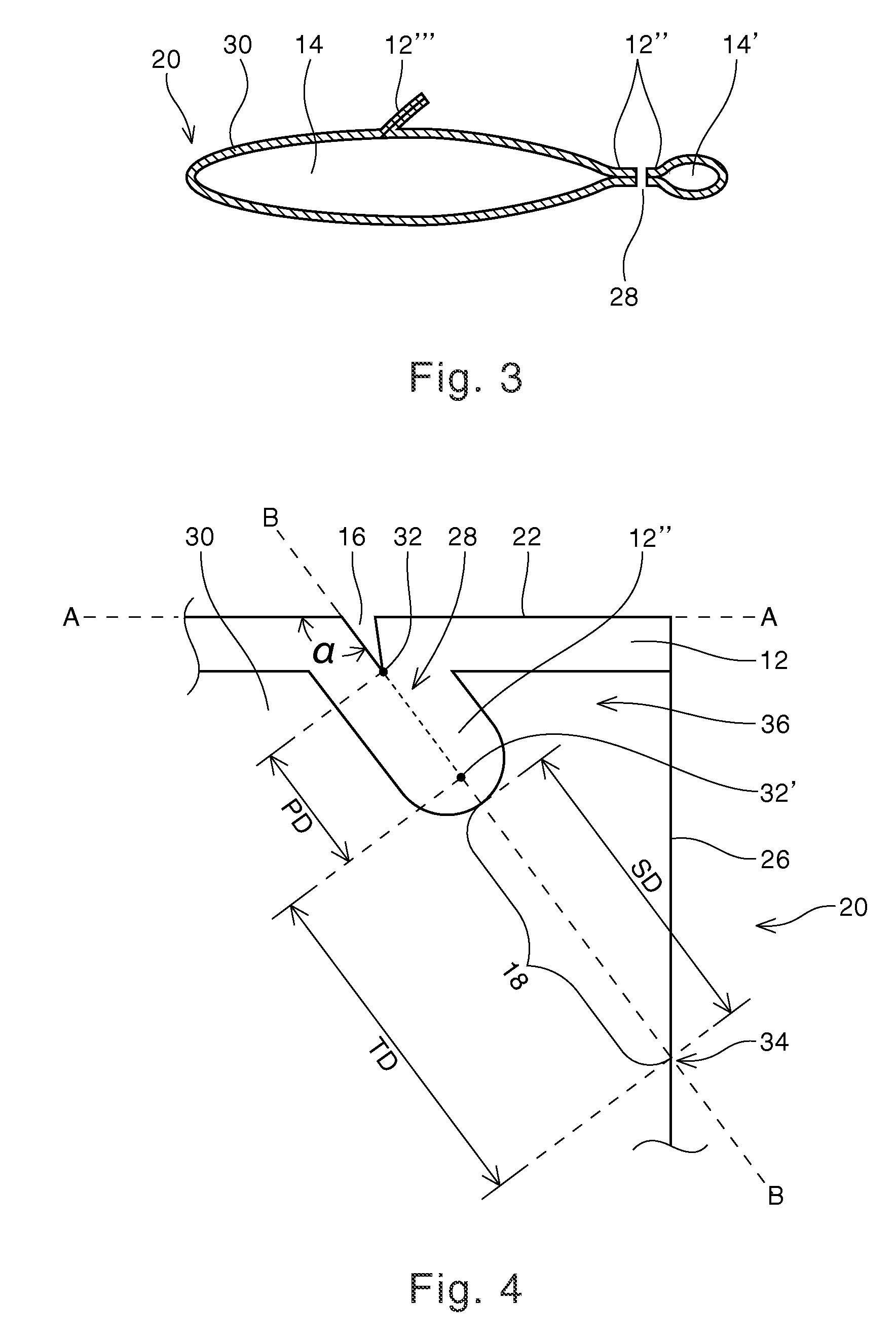

example 1

[0047]Pouches according to FIG. 2, FIG. 4, and FIG. 7, are formed on an autopacking machine from a sheet using the sealing jaw of FIGS. 5-6. The autopacking machine creates all seals by heating to create thermal bonding between the separate sheets. The sheet is a three layer laminate of the film materials polyethylene terepthalate, a metallic film (like MYLAR®), and polyethylene. The sheet is provided on a roll which feeds into the autopacking machine and is stretched onto an area where the tube is formed by sealing a line in the machine direction. The tube has a leading edge which is sealed to form a first seal using the sealing jaws according to FIGS. 5-6. A predetermined weight (2 kg) of laundry detergent is filled into and flows down the tube and the tube is sealed using the sealing jaws of FIGS. 5-6 to form a filled pillow bag containing 2 kg of granular laundry detergent. The process then repeats itself for the next pouch.

[0048]The pouch formed above substantially corresponds ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com