Solar energy absorber

a solar energy absorber and solar energy technology, applied in the direction of solar radiation transmission, solar radiation prevention, light and heating apparatus, etc., can solve the problems of low pressure of discharged hot water, too heavy glass plate , /b>, etc., and achieve the effect of reducing weight and improving the external shape of solar energy absorbers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0051]Example 1 of the solar energy absorber relating to the present invention will be explained.

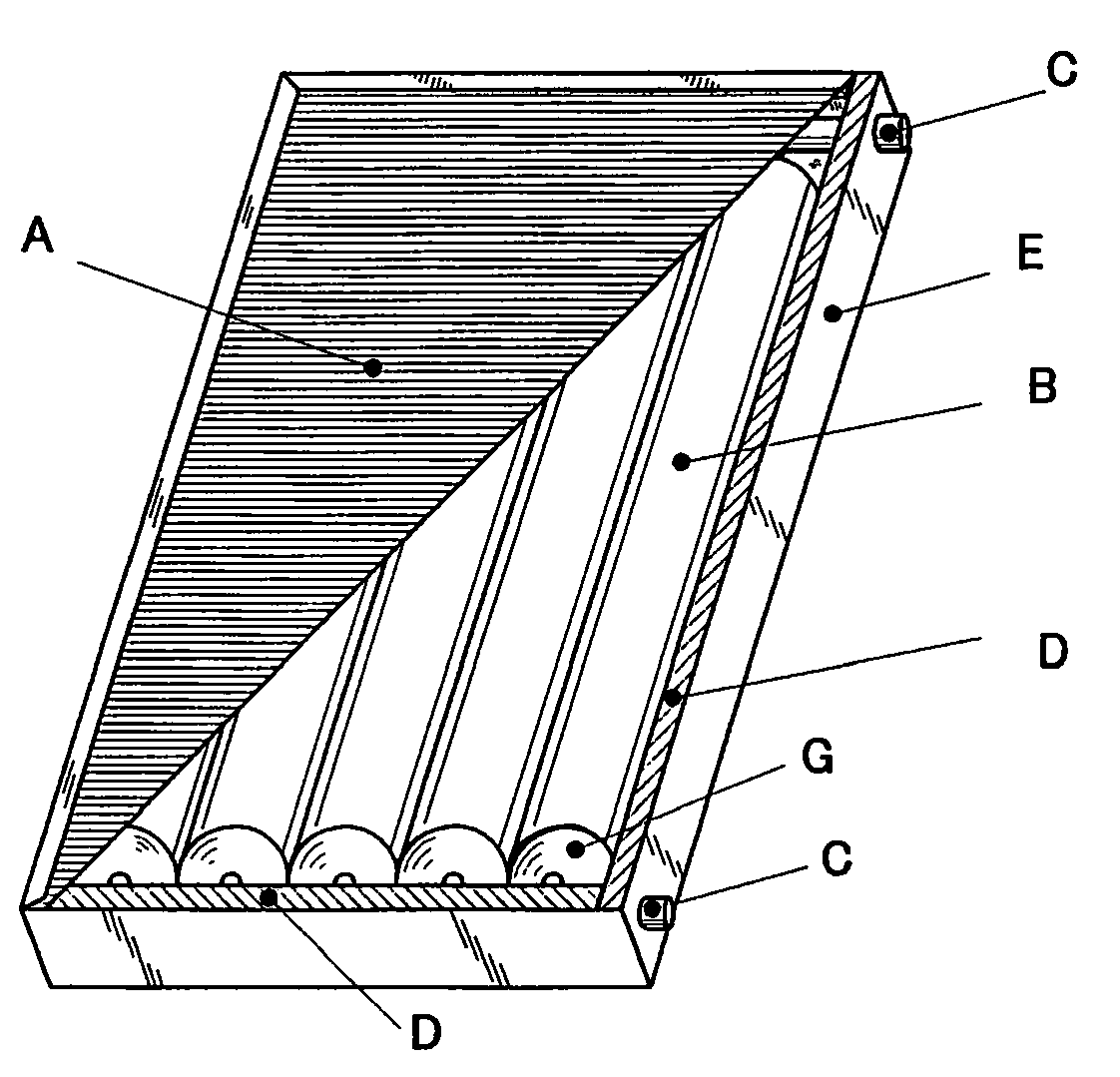

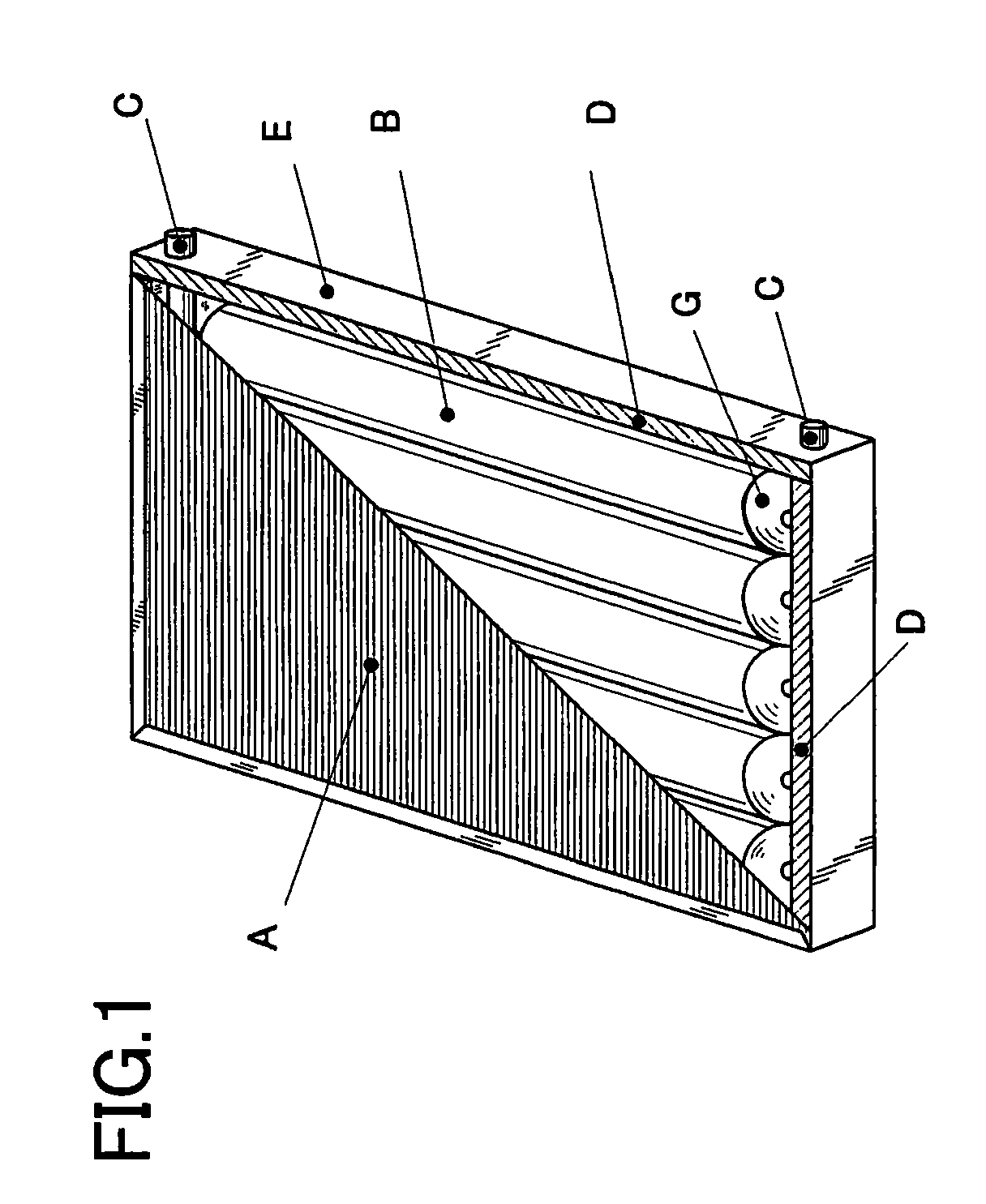

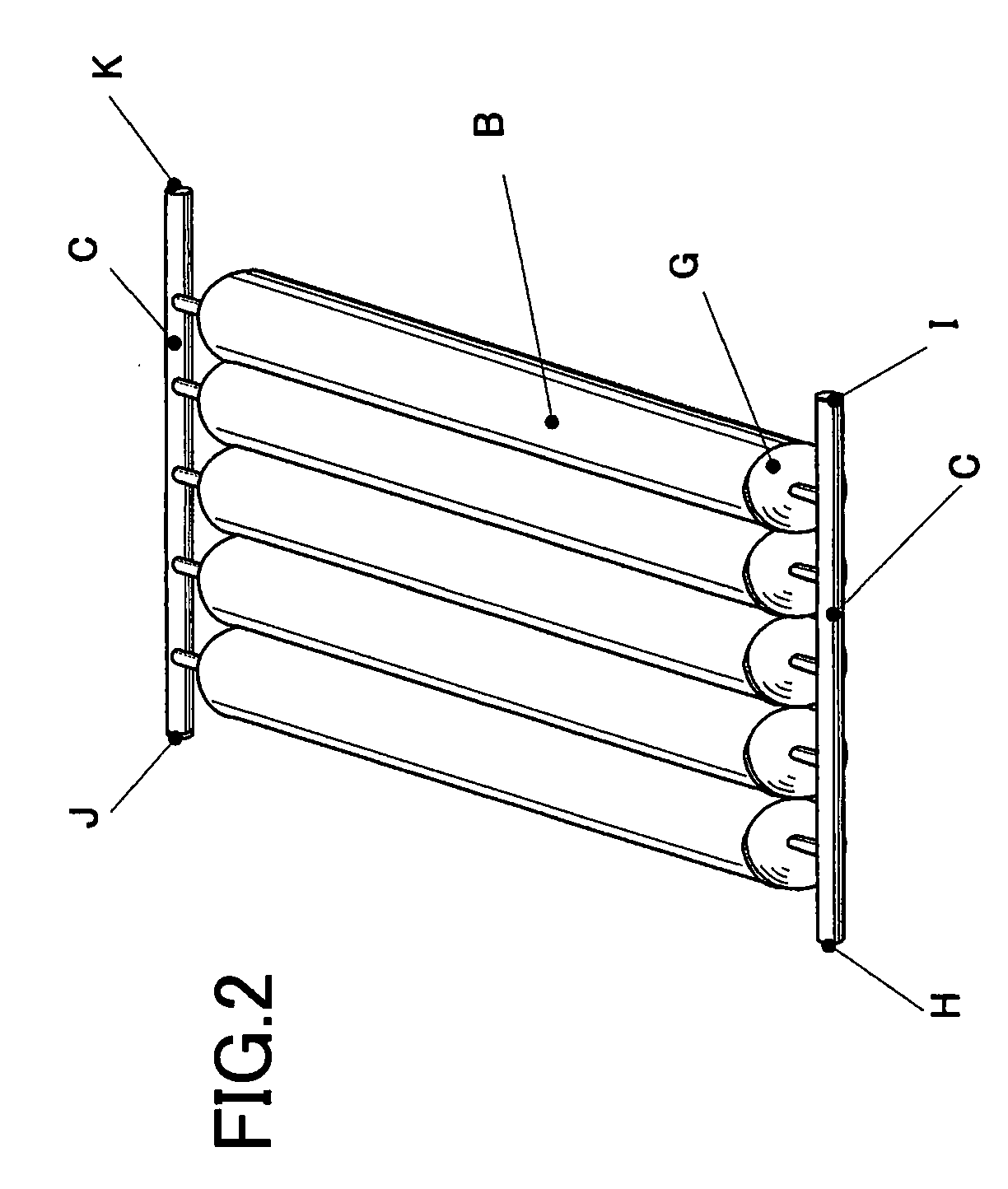

[0052]As shown in FIG. 2, five heat collection tubes B, each of which is composed of stainless steel and has a length of 900 mm, a thickness of 0.5 mm and a diameter of 70 mm, are arranged parallel. The funnel-shaped end plates G are bonded to the ends of the heat collection tubes B. The upper end plates G and the lower end plates G are respectively welded and connected to the header pipes C, so that the integrated water-flowing section can be formed.

[0053]Therefore, the entire water-flowing section has a tubular structure and can resist pressure of 1.0 Mpa, which is twice as high as an ordinary pressure of tap water, i.e., 0.5 Mpa. A capacity of the water-flowing section is about 20 liters.

[0054]The heat collection faces are respectively coated with the heat-absorbing layers by applying a black coating material or vacuum-depositing chrome layer thereon.

[0055]As shown in the sectional vi...

example 2

[0067]Example 2 of the solar energy absorber relating to the present invention will be explained with reference to FIG. 7. FIG. 7 is a transverse sectional view of the solar energy absorber.

[0068]The lower parts (the lower parts of the outer circumferential faces) of the heat collection tubes B contact a vacuum heat insulating material L.

[0069]Since the heat collection tubes B contact the vacuum heat insulating material L, the heat collection tubes B can be suitably held and heat transmission caused by the contact can be highly restrained. Therefore, the heat-retaining property of the solar energy absorber can be highly improved.

[0070]In Example 2, a bottom part of the heat-retaining box D, which is composed by a glass wool heat insulating material, is covered with the vacuum heat insulating material L. Further, inner faces of side walls of the heat-retaining box D are also covered with the glass wool heat insulating material. However, the structure of the heat-retaining box D is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com