Primary aluminum hydride battery

a technology of aluminum hydride and primary cells, which is applied in the direction of fuel and primary cells, cell components, electrochemical generators, etc., can solve the problems of low volumetric capacity, difficult and hazardous handling, and insufficient capacity for some applications

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

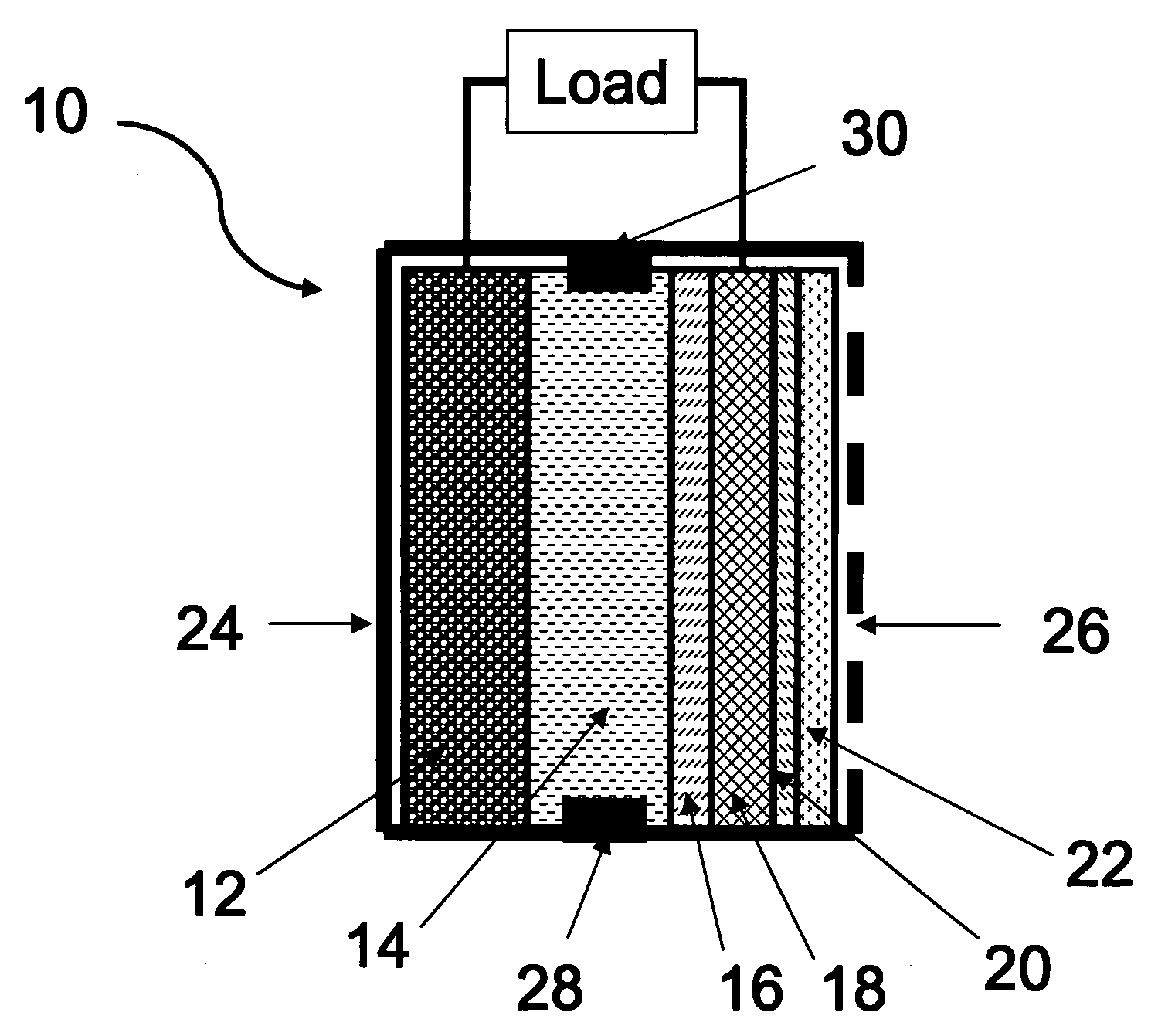

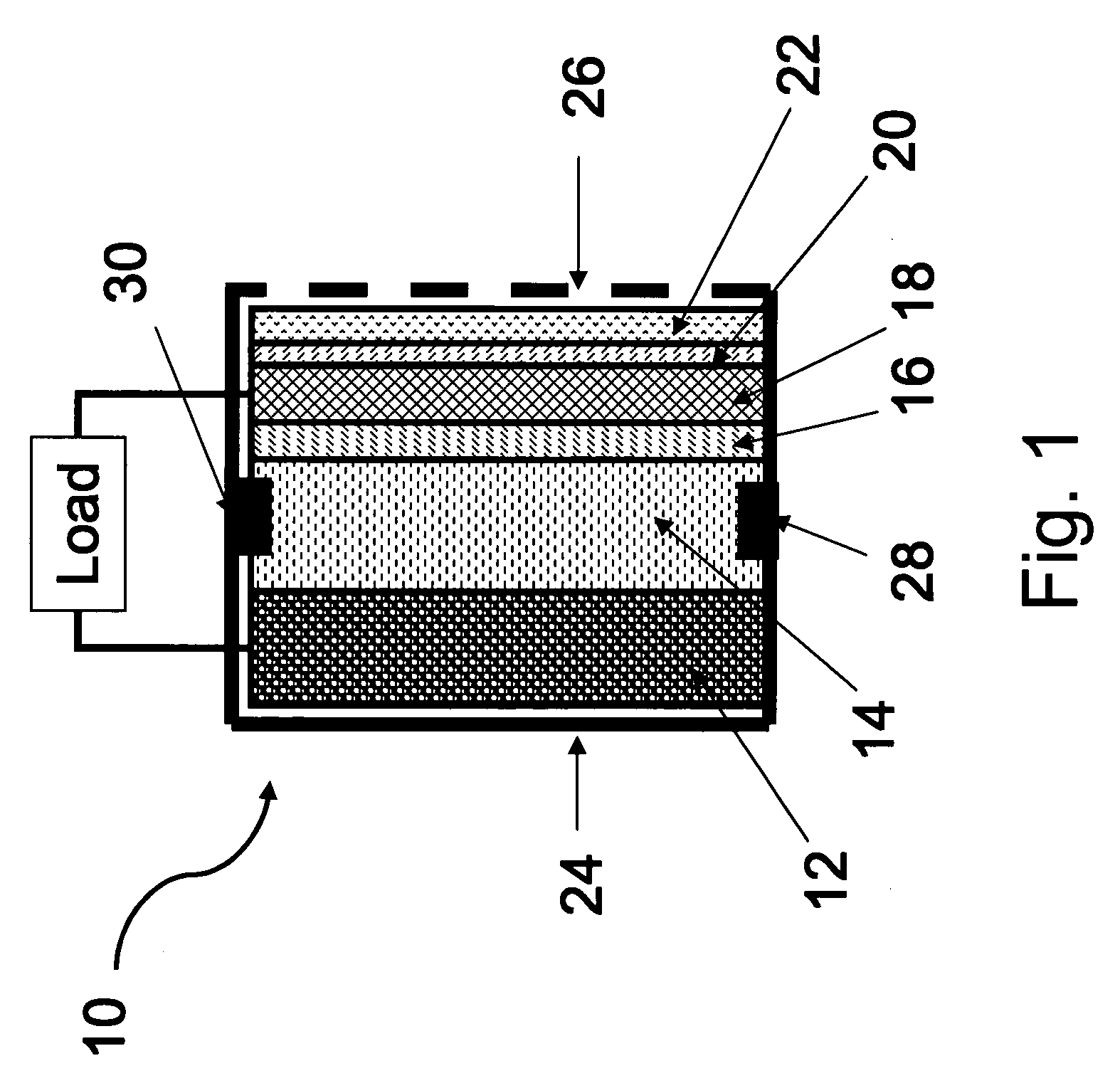

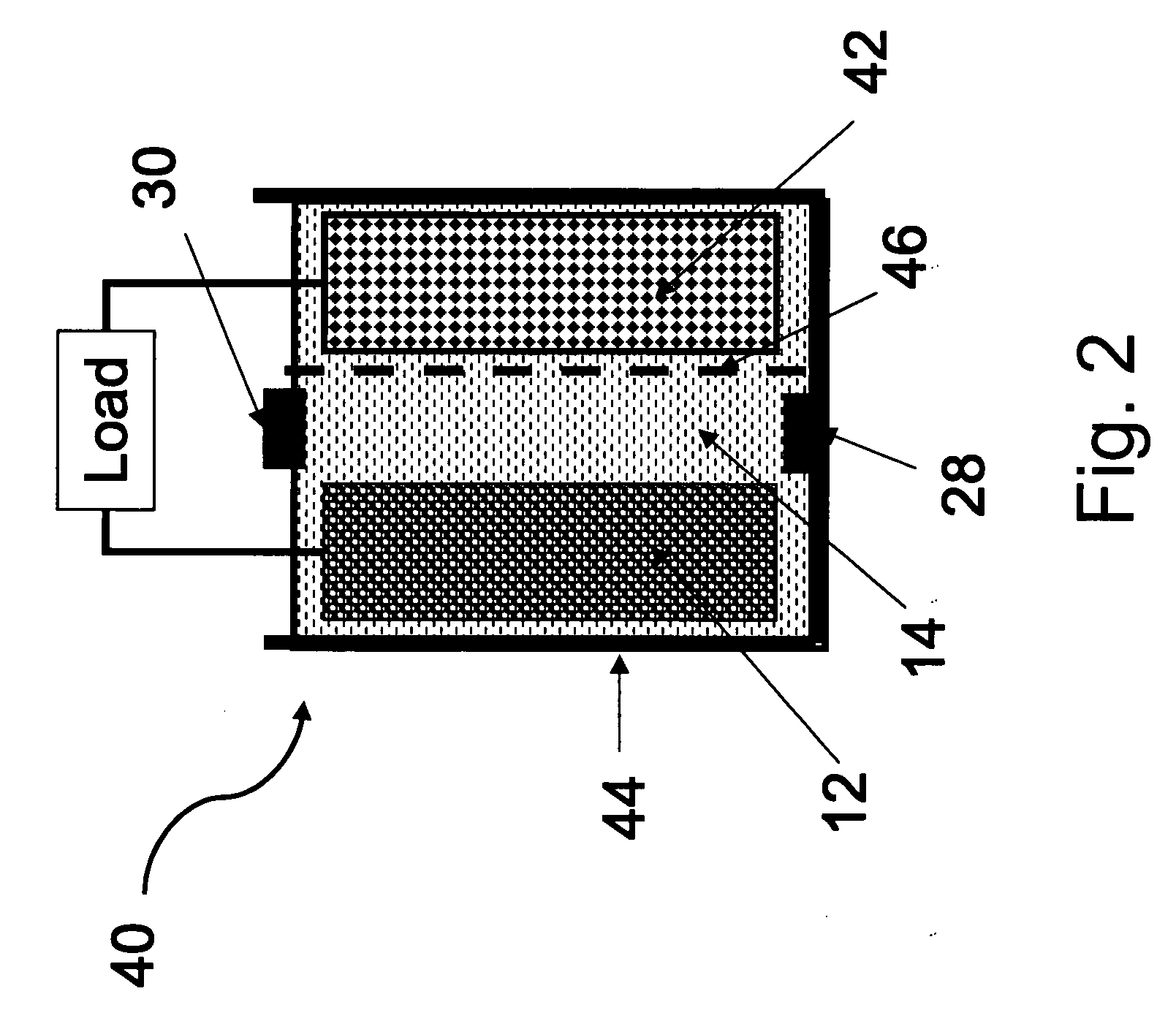

Image

Examples

example

[0025]To demonstrate the discharge ability of an aluminum hydride anode, the electrode with the following composition has been built: 50 wt. % AlH3 prepared accordingly the procedure described by F. M. Brower et al. in Journal of the American Chemical Society 1976, v. 98, pp. 2450-3, 40 wt. % Ni as a current collector, 10% PVDF as a binder pressed on a stainless steel mesh. The electrode was immersed in a beaker type electrochemical cell with a nickel foam counter electrode and the Ag / AgCl reference electrode filled with 1 M (5.8 wt %) solution of NaCl in acetate buffer (pH=6.4) as electrolyte. At the electrode potential above 1.1 V (1.31 V vs, NHE) electrochemical reaction with evolution of hydrogen gas at the cathode and formation of a cloudy precipitate of Al (OH)3 near the anode started. The demonstrated cell potential is close to the potential of a cell comprising an aluminum metal anode, with neutral (pH close to 7) water as the anolyte (1.48 V).

[0026]The cell reactions can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com