Joining unit

a technology of joining unit and component, applied in the direction of automatic control device, feeding apparatus, dynamo-electric machine, etc., can solve the problems of affecting the operation of the unit, the damage of the component of the joining unit, and the relatively complex system in which external units perform essential control functions, etc., to achieve simple and cost-effective construction, high functionality and safety of us

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

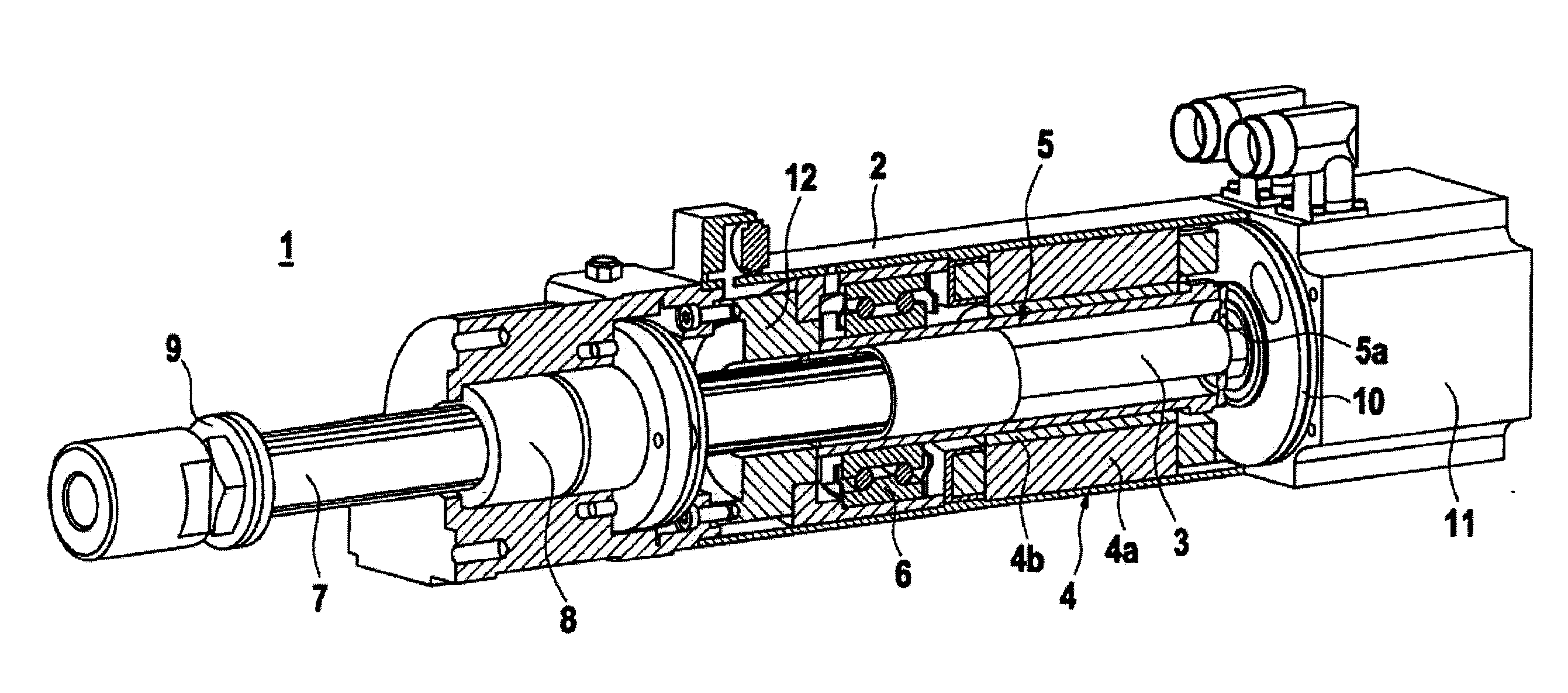

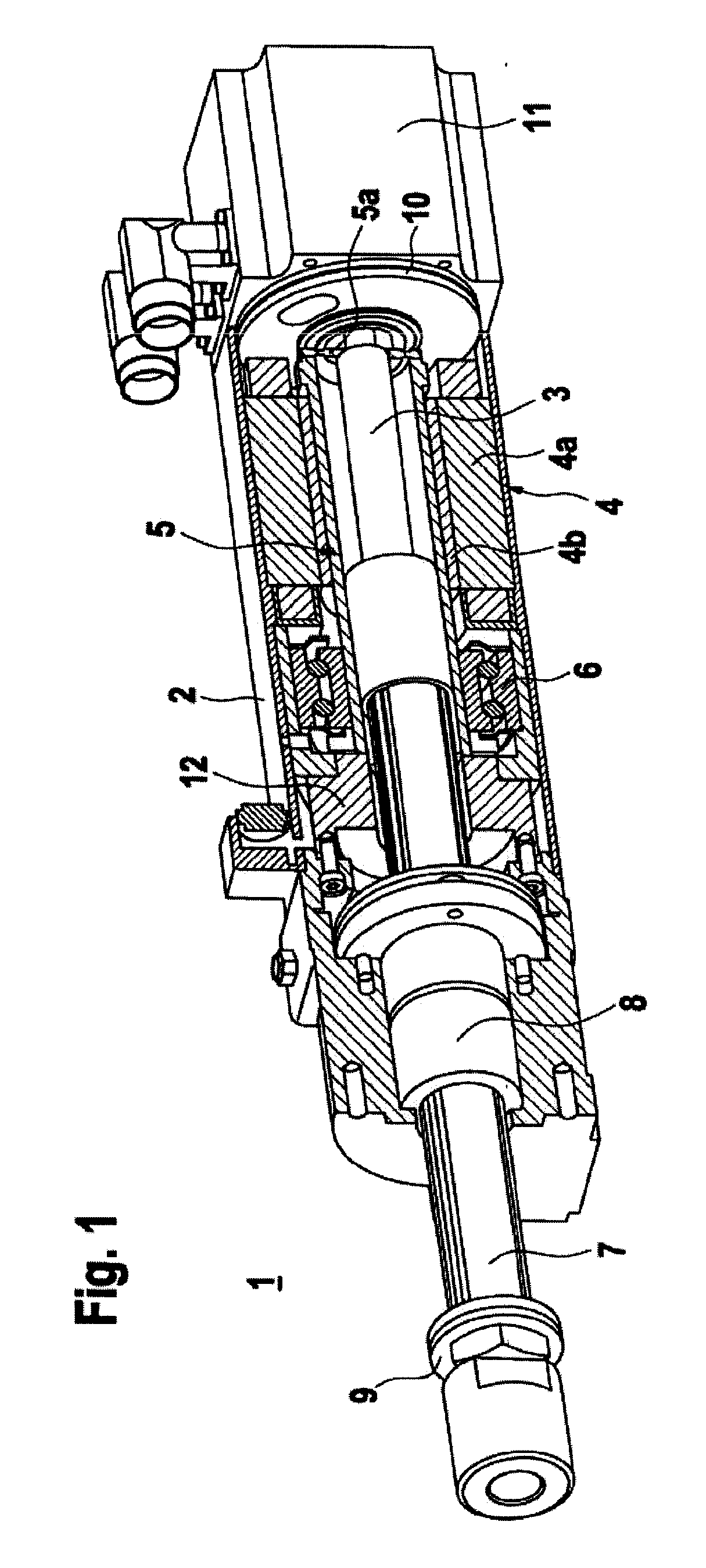

[0036]FIG. 1 shows an example of a joining unit 1. The joining unit 1 is integrated into an axially symmetric housing 2.

[0037]A spindle 3 is placed in the interior of the housing 2 the longitudinal axis of which extends in the axis of symmetry of the housing 2. Preferably, the spindle 3 is embodied as a ball bearing screw or a planetary roller drive.

[0038]Driving of the spindle 3 is performed by means of a hollow shaft motor 4 and, thus, without any use of a gear. The hollow shaft motor 4 is in the form of an electric drive. In the present case, the electric drive is embodied as a servo motor. The stator 4a of the electric drive is arranged at the inner wall of the housing 2 and concentrically with the spindle axis. A tubular body 5 is firmly connected with the spindle 3. The tubular body 5 is essentially in the form of a hollow cylinder the lateral surface of which is arranged concentrically with and in a predetermined distance to the spindle 3. At its front face the tubular body 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| forces | aaaaa | aaaaa |

| force/displacement | aaaaa | aaaaa |

| force | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com