Method for improving performance of high temperature superconductors within a magnetic field

a superconductors and magnetic field technology, applied in the direction of superconducting magnets/coils, magnetic bodies, instruments, etc., can solve the problems of increasing the barrier to their commercialization, affecting the cost/performance ratio of hts products, and rapid reduction of the ability, etc., to achieve the effect of improving the performance of the magnetic field

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

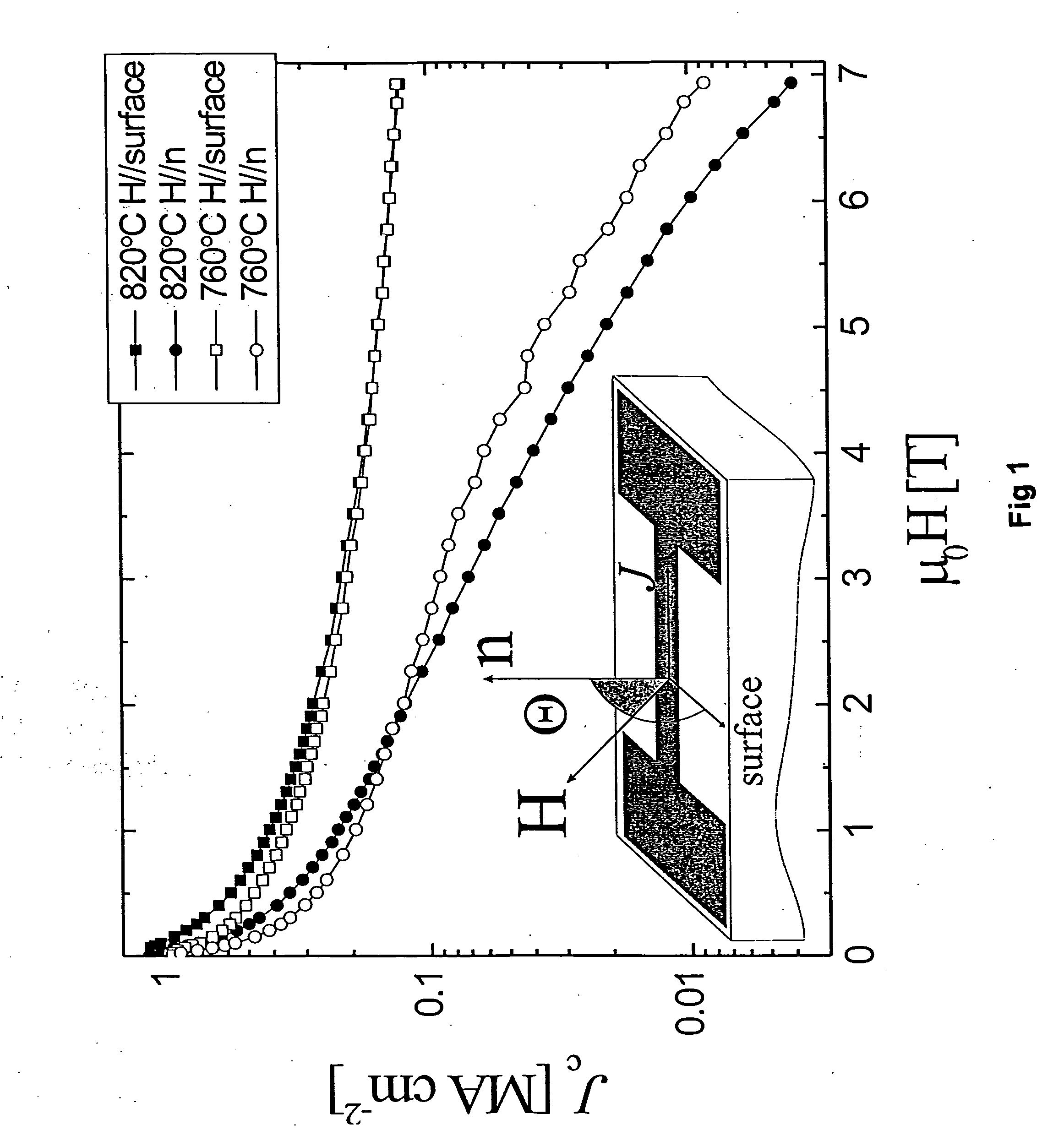

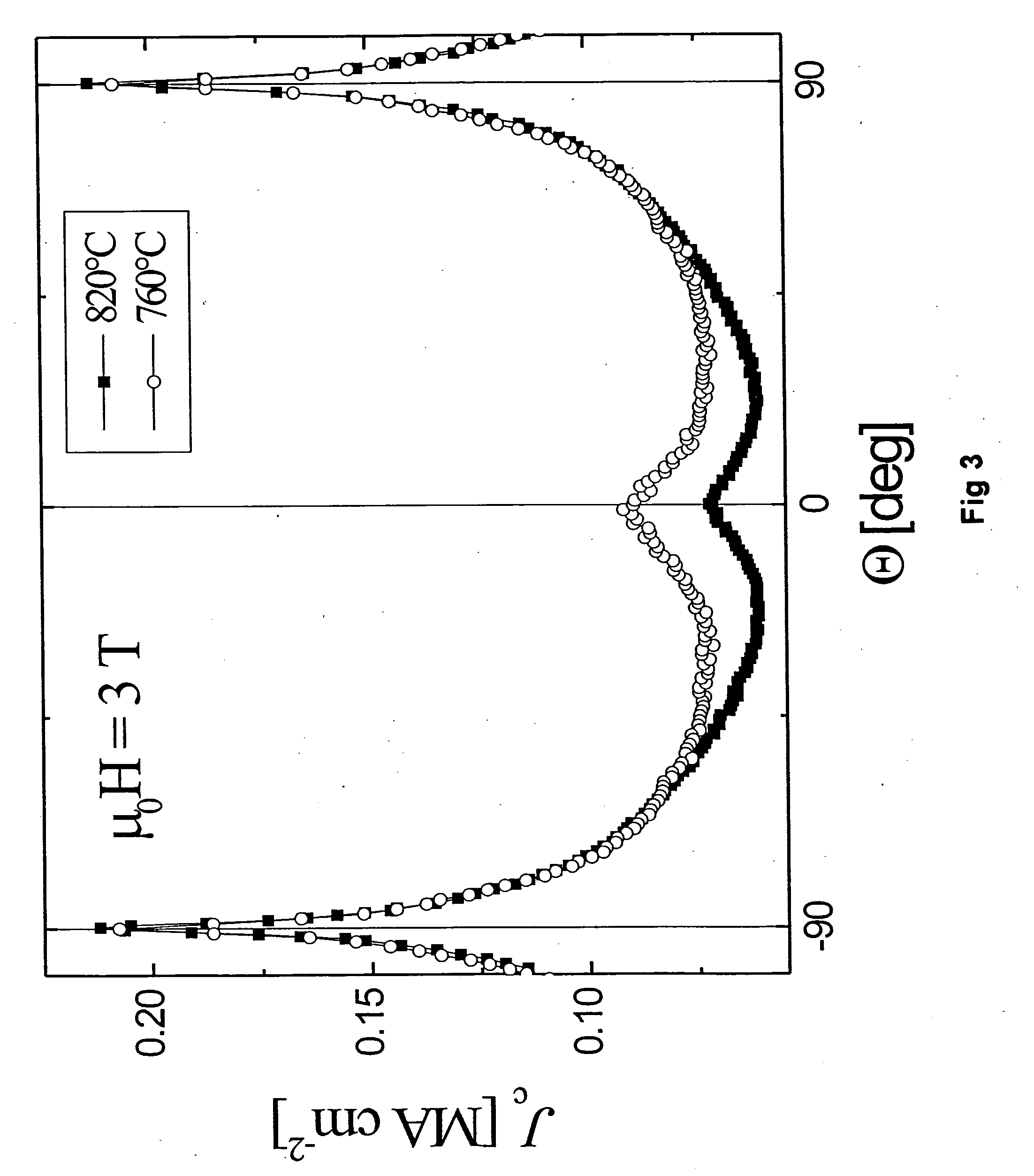

[0031]A series of coated conductors were formed with the following structure: a Hastelloy base substrate / a layer of aluminum oxide (Al2O3) / a layer of yttrium oxide (Y2O3) / a layer of IBAD-MgO / a homoepitaxial layer of MgO / a layer of strontium titanate (STO) / a layer of YBCO (1 to 5 microns). The layer of STO was deposited by pulsed laser deposition using conditions for such deposition as described by Wang et al., J. Mater. Res., v. 19, no. 6, pp. 1869-1875 (2004), such reference incorporated herein by reference. Deposition temperature was varied from 670° C. to 860° C. at constant oxygen pressure of 300 milliTorr. From this structure, the measured properties of the YBCO layer was: a superconducting transition temperature (Tc) of 89 K, and a critical current density (Jc) of 1.0 MA / cm2 with YBCO thickness at 4.0 μm.

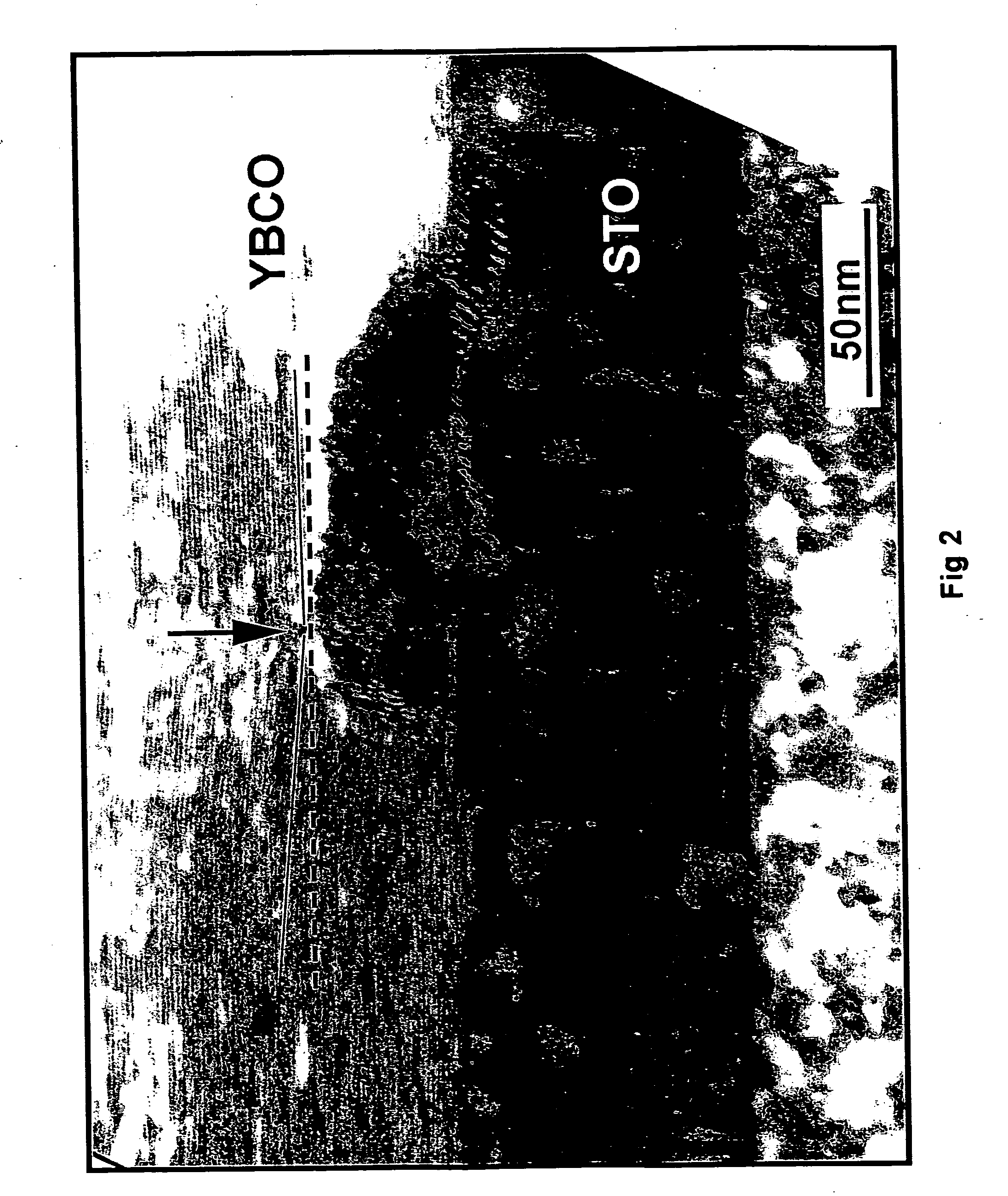

[0032]FIG. 2 shows the SEM for depositions at varying temperatures. It was found that the number of particulate outgrowths were greater at the lower temperatures. It was found...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| magnetic field | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com