Pleated multi-layer filter media and cartridge

a filter media and multi-layer technology, applied in the field of pleated filter media, can solve the problems of brittleness, unable to withstand elongation, and limited maximum surface area and media packing density,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

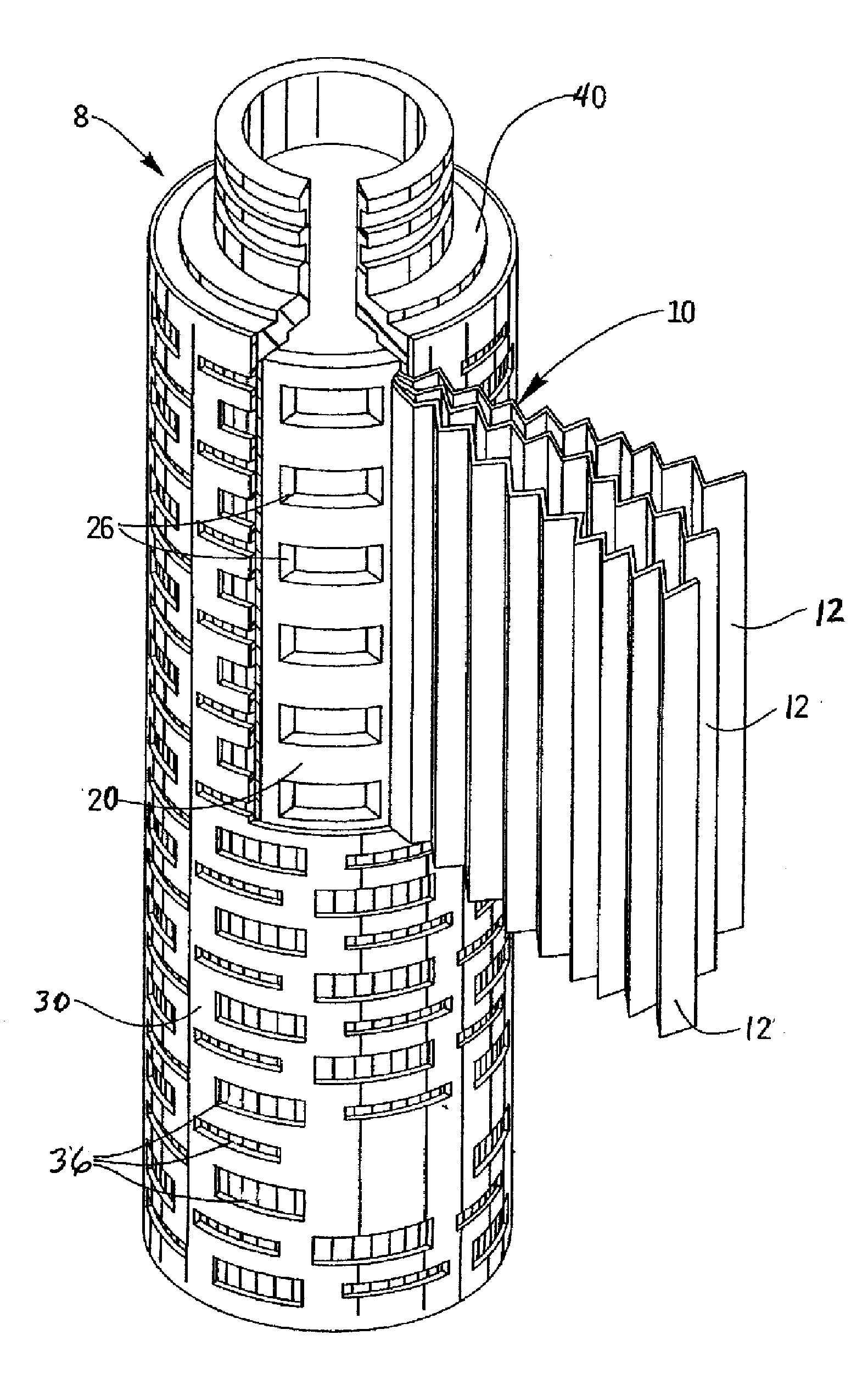

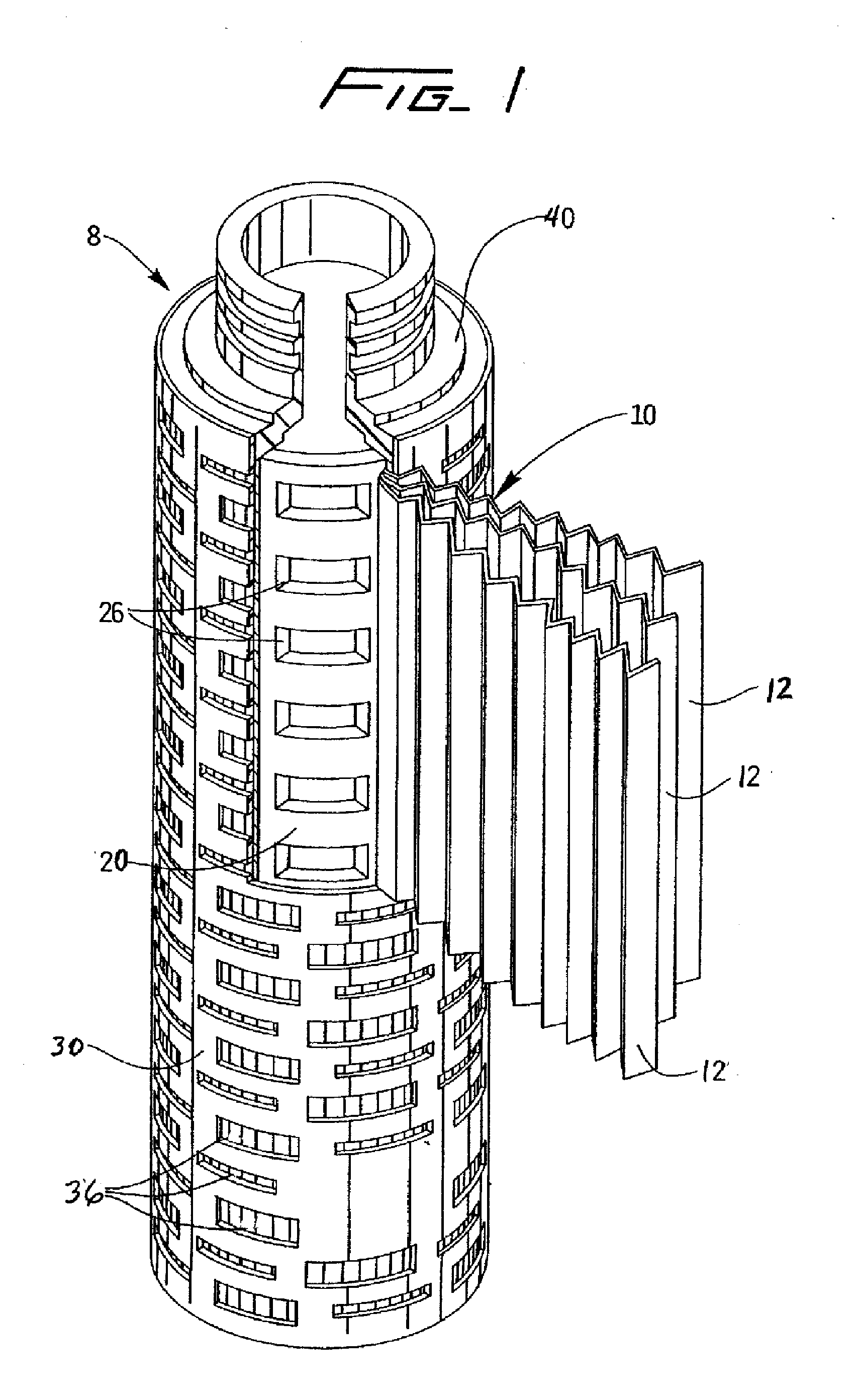

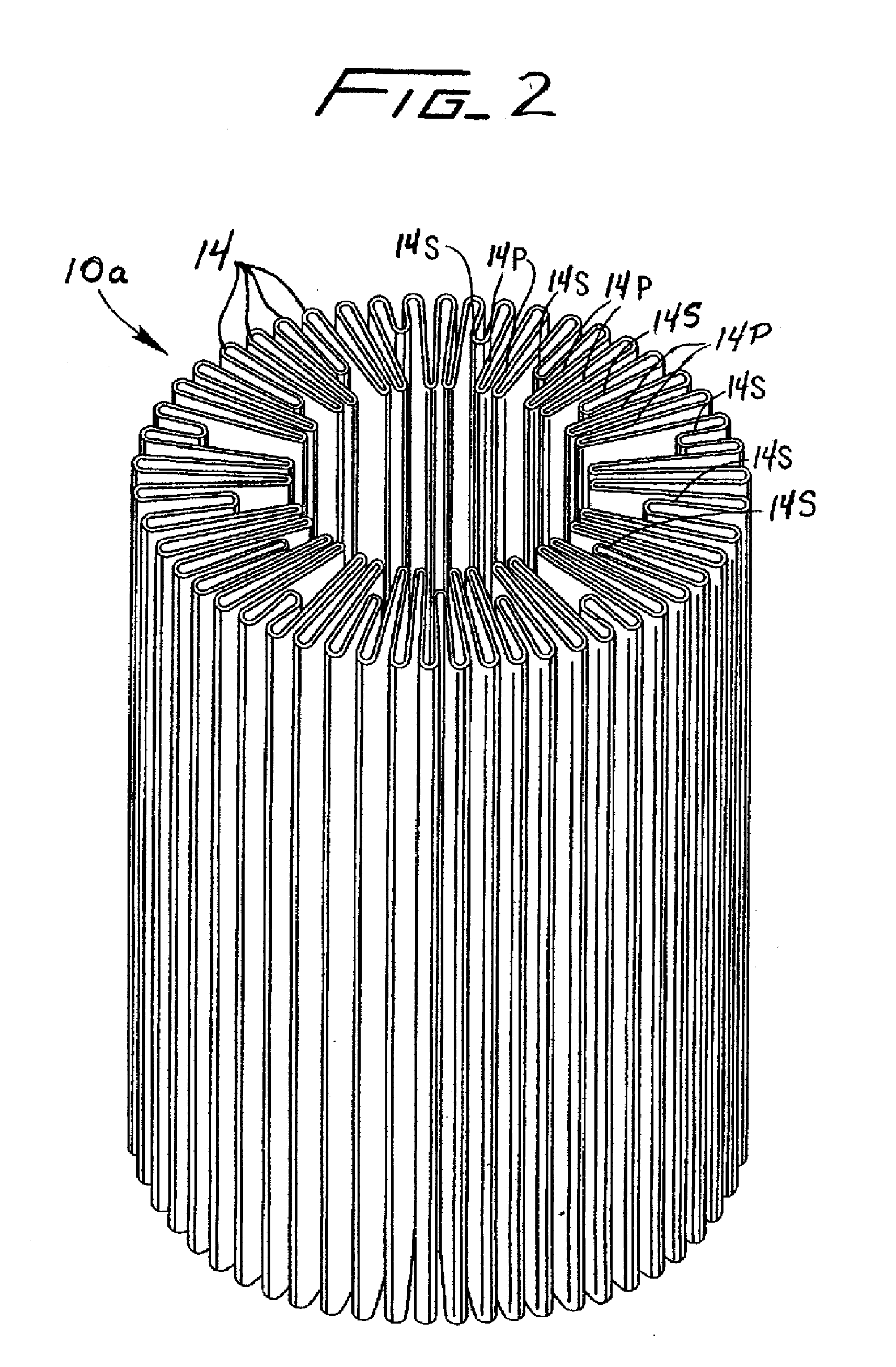

Image

Examples

example embodiment

[0068]In accordance with one specific representative embodiment of the depth filter media, a method of forming a filter element is herein described. The individual depth filter media layers are formed by making about a 1% slurry using water that has been treated by reverse osmosis to improve its purity (RO water). A typical slurry solution consists of commercially available Kraft pulp, about 6% refined pulp (about −250 CSF, Canadian Standard Freeness, as described in U.S. Pat. No. 4,305,782) and about 68% diatomaceous earth by dry weight, as would be known by one skilled in the art. In one representative formulation two types of resin, such as, for example, the representative charge modifying recipe as disclosed in U.S. Pat. No. 5,085,784 with chemical structures as further disclosed in U.S. Pat. No. 4,473,474, the disclosure of each is herein incorporated by reference to the extent not inconsistent with the present disclosure, are added at about 5.2% and about 1.3% by weight resin ...

example 1

[0149]In a specific example of media forming the individual depth filter media layer were formed by making about a 1% slurry using water that has been treated by reverse osmosis to improve its purity (RO water). The slurry solution consisted of about 26.8% commercially available Kraft pulp, about 7.3% refined pulp (about −250 CSF, Canadian Standard Freeness, as described in U.S. Pat. No. 4,305,782) and about 65.9% 0.02 D'Arcy's diatomaceous earth (World Minerals Celite 507) by dry weight, as would be known by one skilled in the art. A Polyamine-Epichlorohydrin Resin (Hercules Polycap 1884) was added at about 1.5% by weight resin solids on slurry solids.

[0150]The resultant slurry was fed into a papermaking machine (Fourdrinier type). The slurry was laid down at a constant thickness on to a moving screen. The screen speed for this process was about 3 ft / min. The screen was over vacuum slots to remove most of the RO water from the slurry. The applied vacuum pressures ranged from about ...

example 2

[0158]The unpleated flat stock, as described in the specific example (Example 1) media, was cut into a 47 mm disk using a dye from each of the rolls used previously to make the filter cartridge composed of the filter module and the pleated filter element. The filter disks were then placed in to a Cuno 47 mm housing Part number 70225-01 where the media were placed in the same order as in the way the rolls were used to create the filter element as described previously and the housing was sealed. This process was repeated for 1 additional housing resulting in 2 housings assembled in the same manner. Using a flow of 45.4 ml / min resulting on a flux of 37.5 liters per minute per square meter, the filters were challenged with 0.16 g / L Grandma's Molasses—“Robust Flavor” (Green Label) brand molasses dispersed in water. The pressure drop across the filter was monitored and the test was stopped when a pressure differential of 25 PSID was recorded across the filters. The resulting throughput fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com