Moisture impermeable fire-barriers

a fire-barrier and moisture-impermeable technology, applied in the field of fire-barriers, can solve the problems of affecting the service life of workers, and presenting a major fire risk to the structure, and it is difficult if not impossible to prevent moisture from reaching the barrier

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

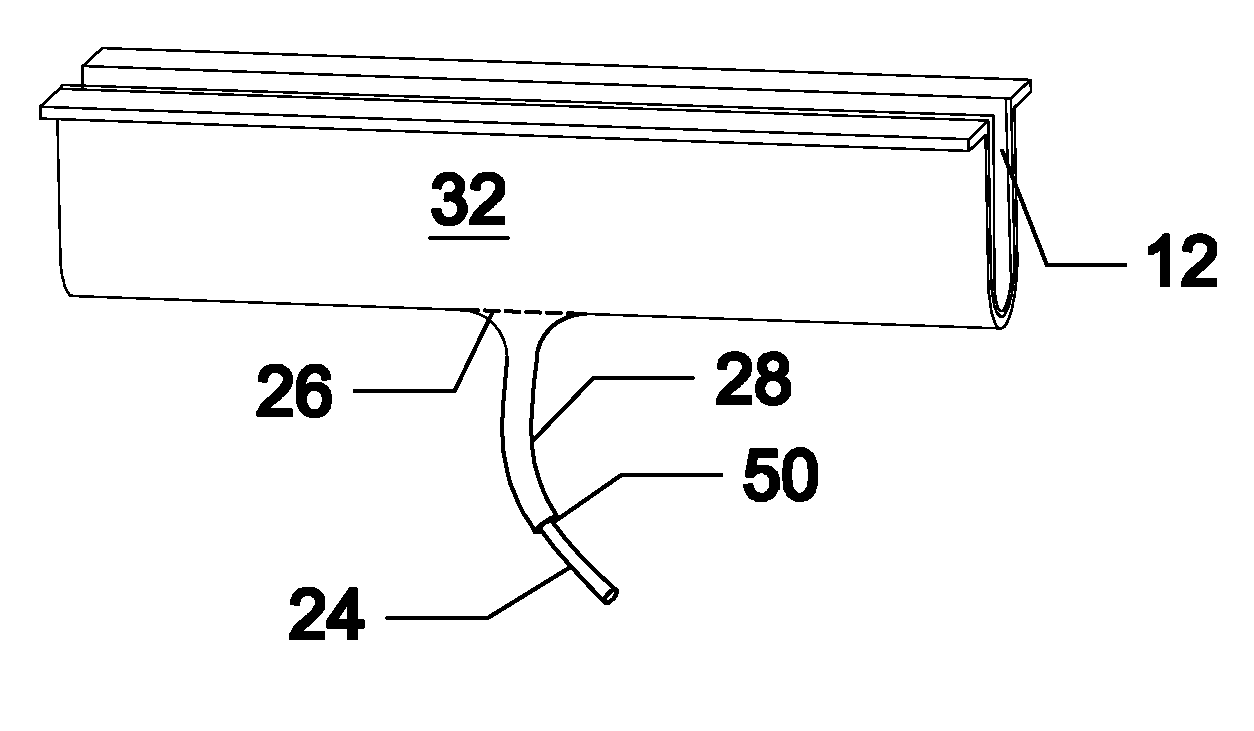

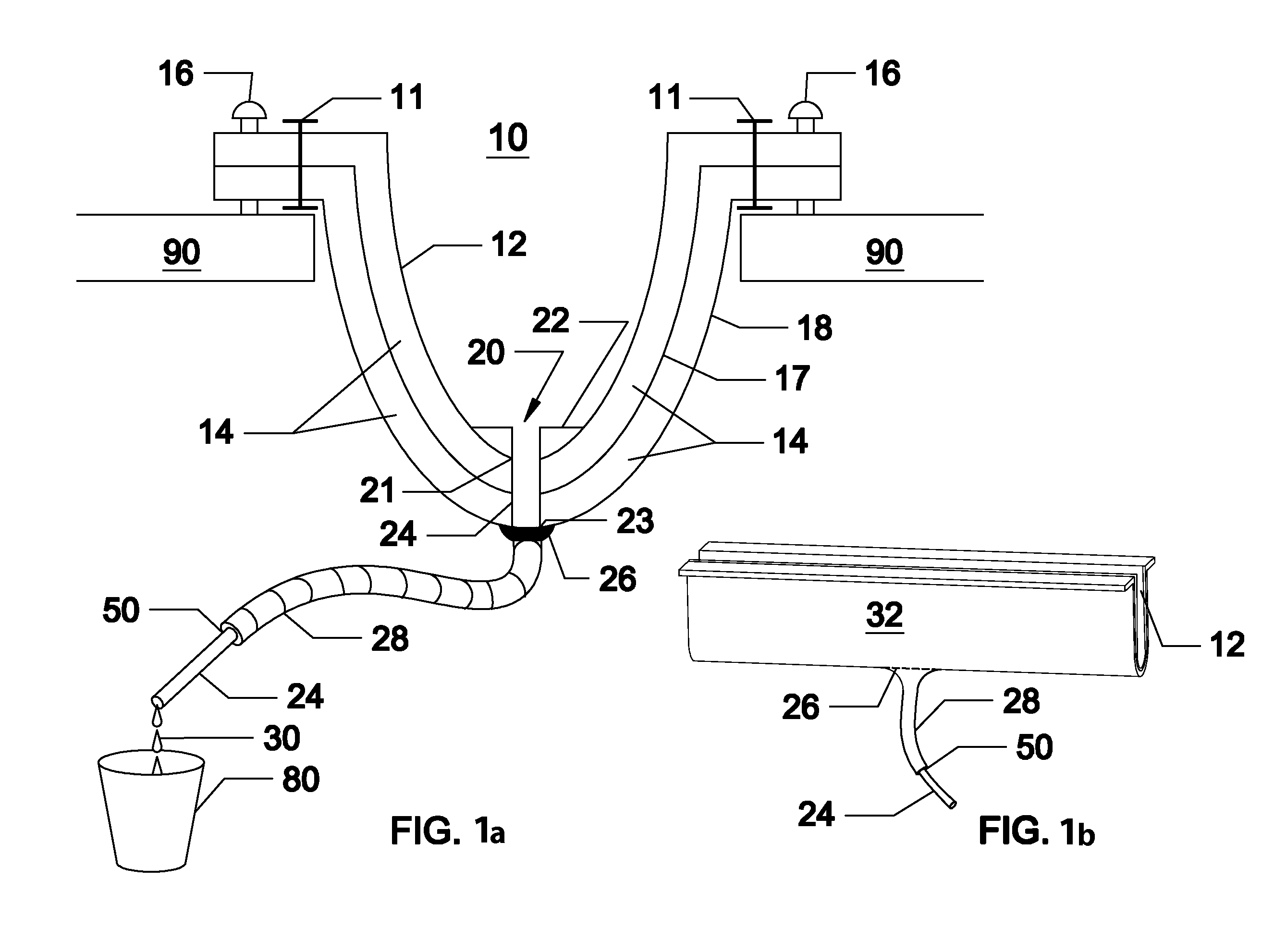

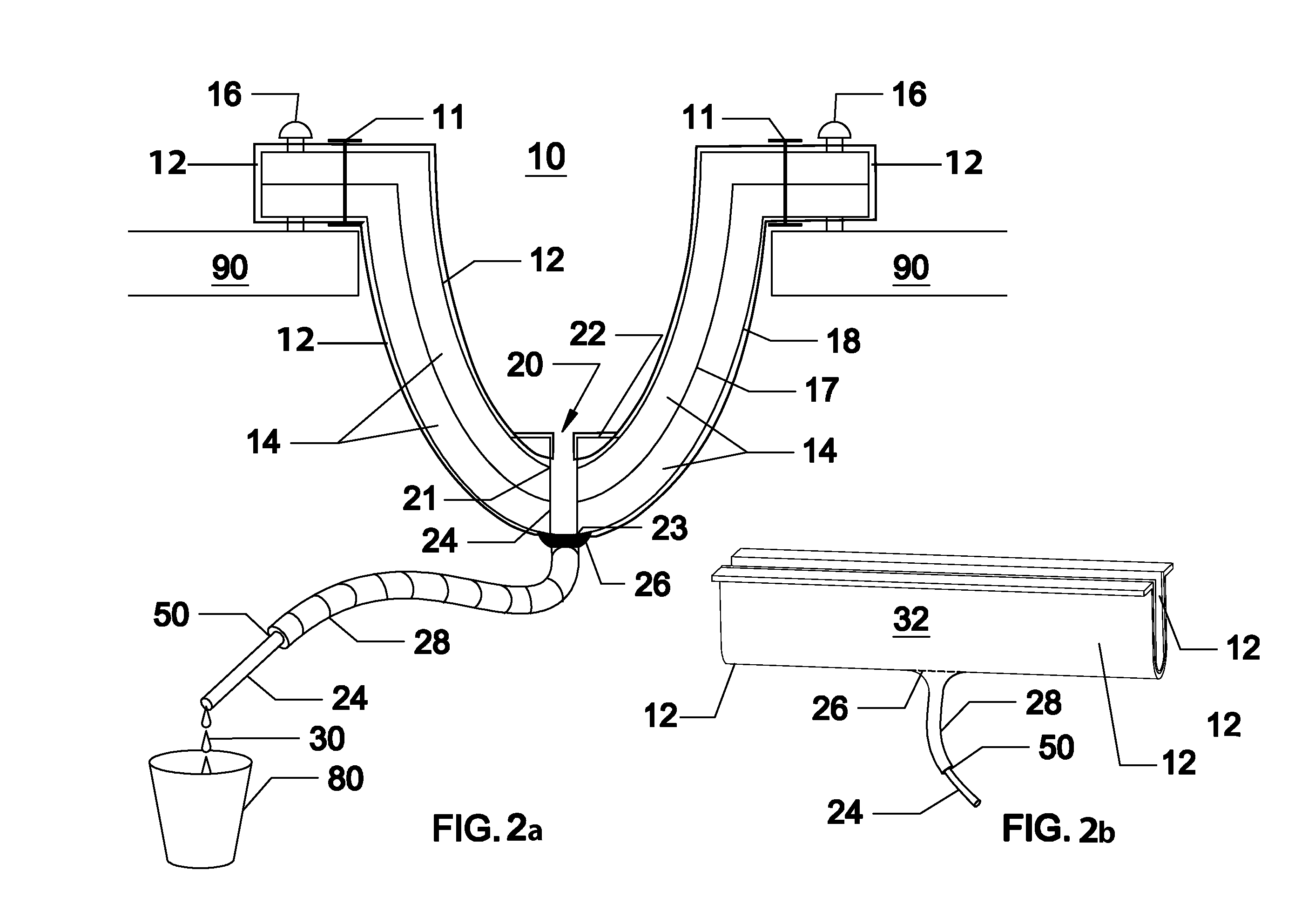

[0095]To provide an understanding of the basic structure of the moisture and gas impermeable barriers contemplated herein, we now refer to the drawings to illustrate exemplary versions of the invention. It should be noted that the disclosed invention is disposed to versions in various sizes, such as shapes, lengths, widths, and thicknesses, as well as to the one or many the multi-directional, multi-dimensional body sections to accommodate the large variety of expansion-joint spaces that require fire-barriers, in addition to variation in shapes, contents, number and composition of layers, materials, and attachment means. Therefore, the versions described herein are provided with the understanding that the present disclosure is intended as illustrative and is not intended to limit the invention to the versions described.

[0096]FIG. 1a is a cross-sectional diagrammatic view of a straight-line top-mount moisture-impermeable fire-barrier of the present invention installed in an expansion-...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thick | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| ninety degree angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com