Tuning-Fork Type Piezoelectric Vibrating Piece and Piezoelectric Device

a piezoelectric and tuning fork technology, applied in the direction of piezoelectric/electrostrictive device details, device material selection, device details, etc., can solve the problems of frequency adjustment that cannot be controlled to a predetermined value, frequency adjustment that cannot be easily adjusted, and collision of tuning portions, etc., to achieve excellent characteristics and suppress the degradation of ci value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

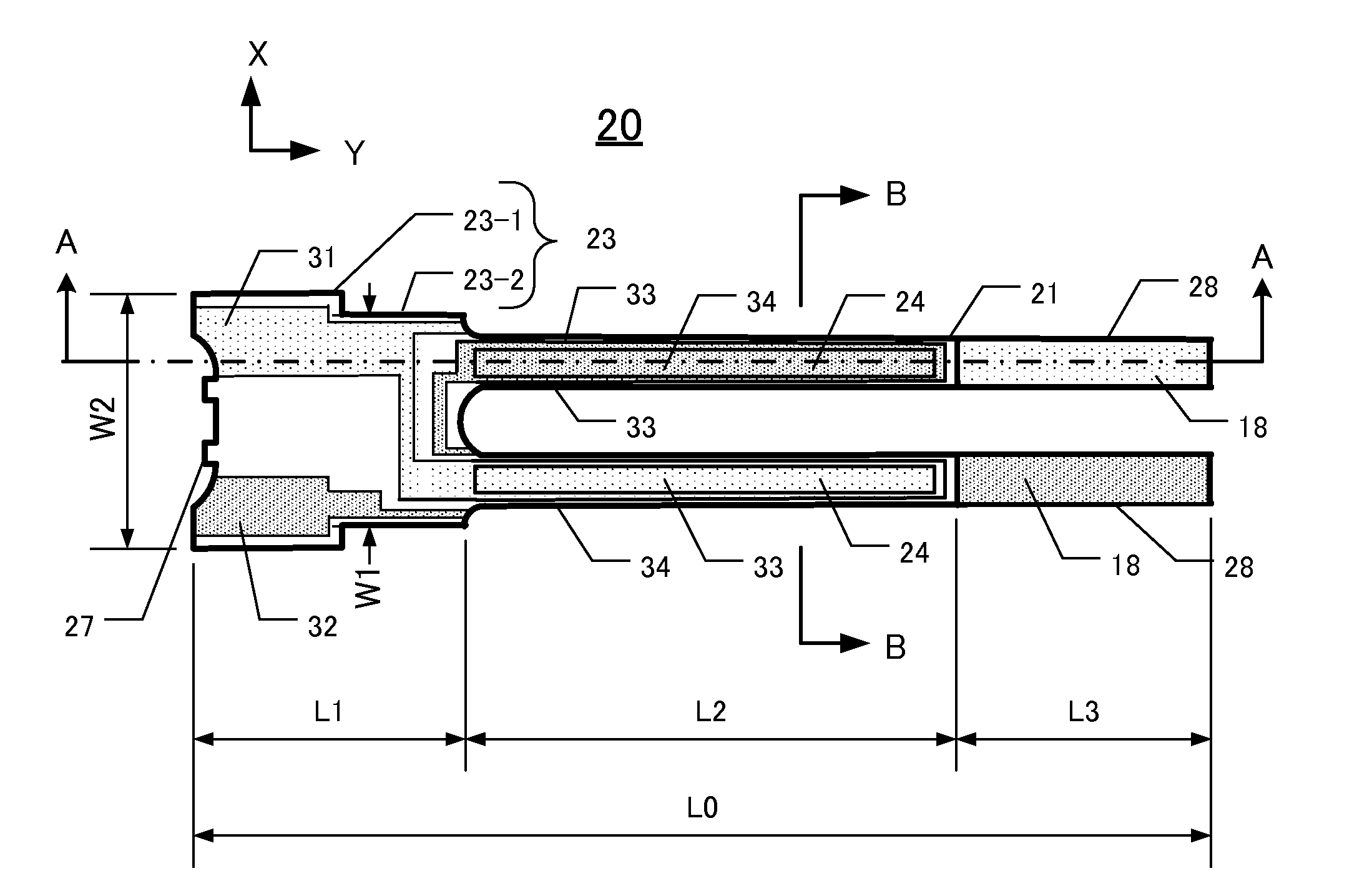

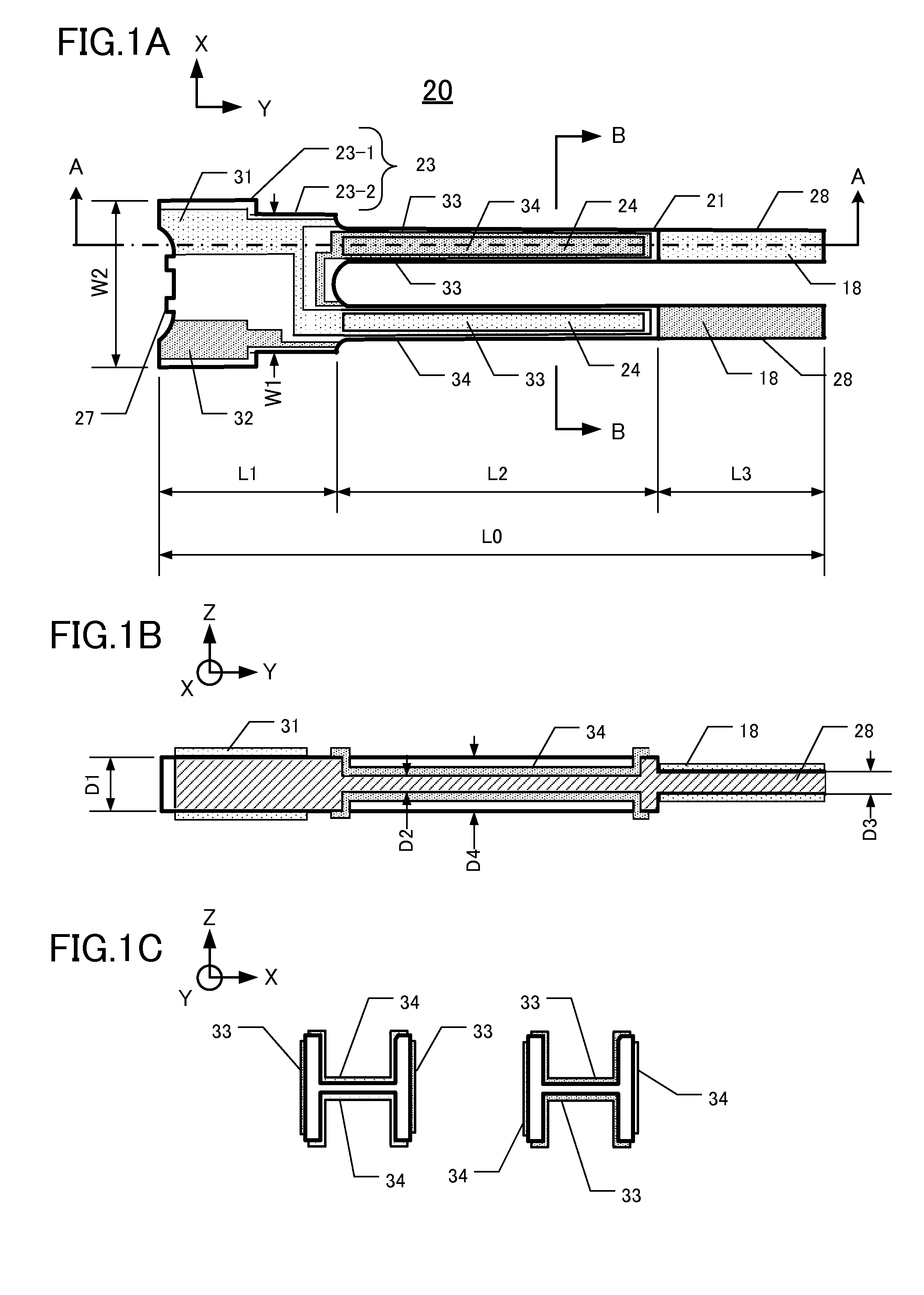

[0051]FIG. 1A is a top view showing whole configuration of the first tuning-fork type crystal vibrating piece 20 of a first embodiment. FIG. 1B is a cross-sectional view taken along line A-A of FIG. 1A. FIG. 1C is a cross-sectional view of a pair of vibrating arms 21 of the first tuning-fork type crystal vibrating piece 20 taken along line B-B of FIG. 1A. The base material of the first tuning-fork crystal vibrating piece 20 is a Z-cut single crystal wafer. As shown in FIG. 1A, the first tuning-fork type crystal vibrating piece 20 is provided with a base portion 23 comprising a first base portion 23-1 and a second base portion 23-2 and a pair of vibrating arms 21 which is bifurcated and extends parallel from the first base portion 23-1 to the right side of FIG. 1A. Tuning portions 28 for frequency adjustment are formed on the distal ends of vibrating arms 21. Connecting portions 27 are formed on the base portion 23 in order to connect the first tuning-fork type crystal vibrating piec...

second embodiment

[0106]FIG. 12A is a top view showing whole configuration of the crystal frame 50. FIG. 12B is a cross-sectional view taken along the E-E line of the FIG. 12A. FIG. 12C is a cross-sectional view taken along the F-F line of the FIG. 12B.

[0107]As shown in FIG. 12A, the crystal frame 50 is comprised of an eighth tuning-fork type crystal vibrating piece 30 having the base portion 23 and the vibrating arms 21, the crystal frame portion 29, the supporting arms 22, and the connecting portions 36. And they are formed integrally as the same thickness. A space 25 is formed between the eighth tuning-fork type crystal vibrating piece 30 and the crystal frame portion 29. The crystal frame 50 is further comprised of a first base electrode 31 and a second base electrode 32 on the crystal frame portion 29, the base portion 23, the supporting arms 22, and the connecting portions 36. The eighth tuning-fork type crystal vibrating piece 30 is very small and oscillates at 32.768 kHz.

[0108]The space 25 de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com