Catalytic heater

a heater and catalytic technology, applied in the field of catalytic heating systems, can solve the problems of difficult to provide small systems, difficult to start by such simple means, and only start combustion, and achieve the effect of reducing weight and being easy to implemen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

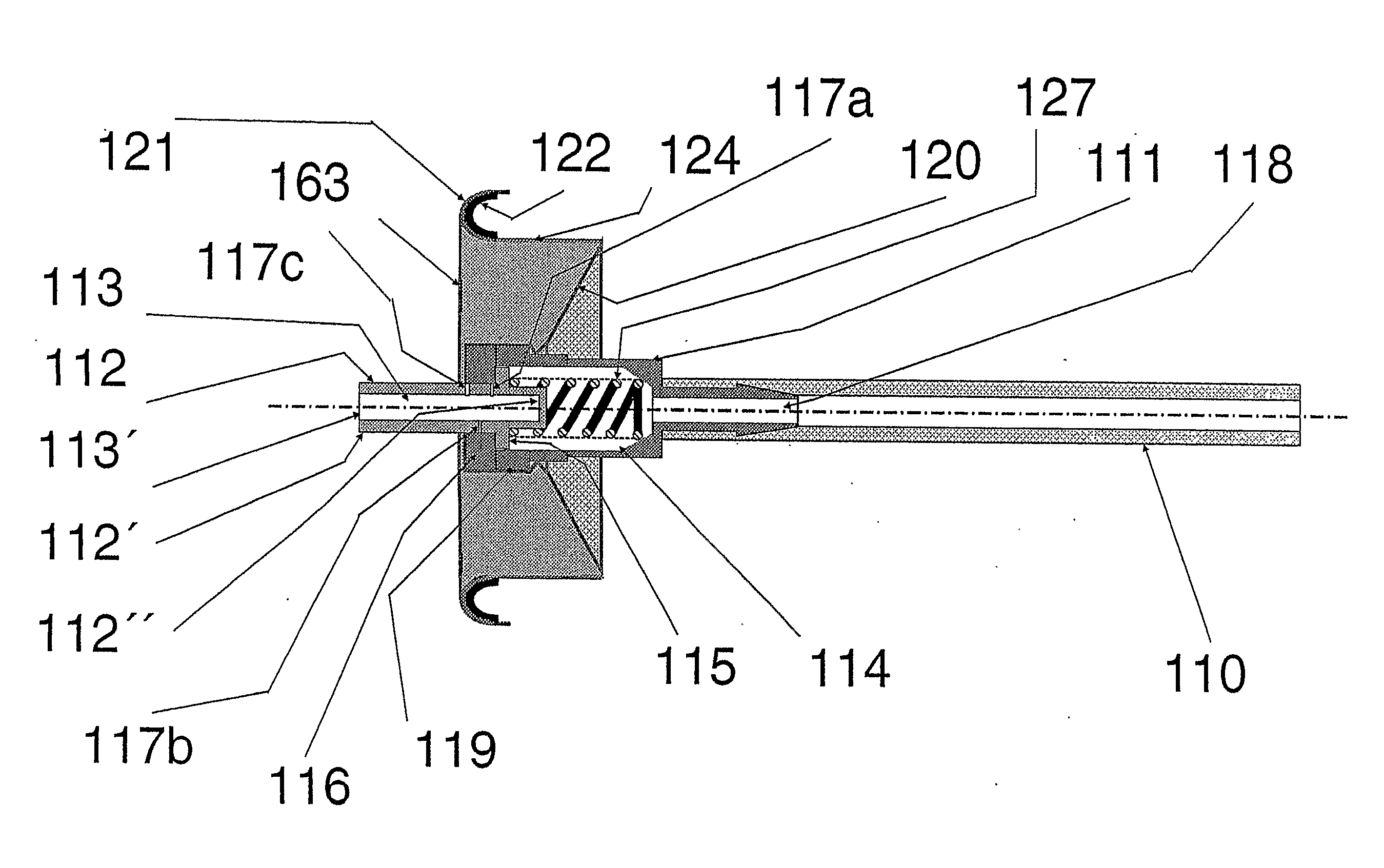

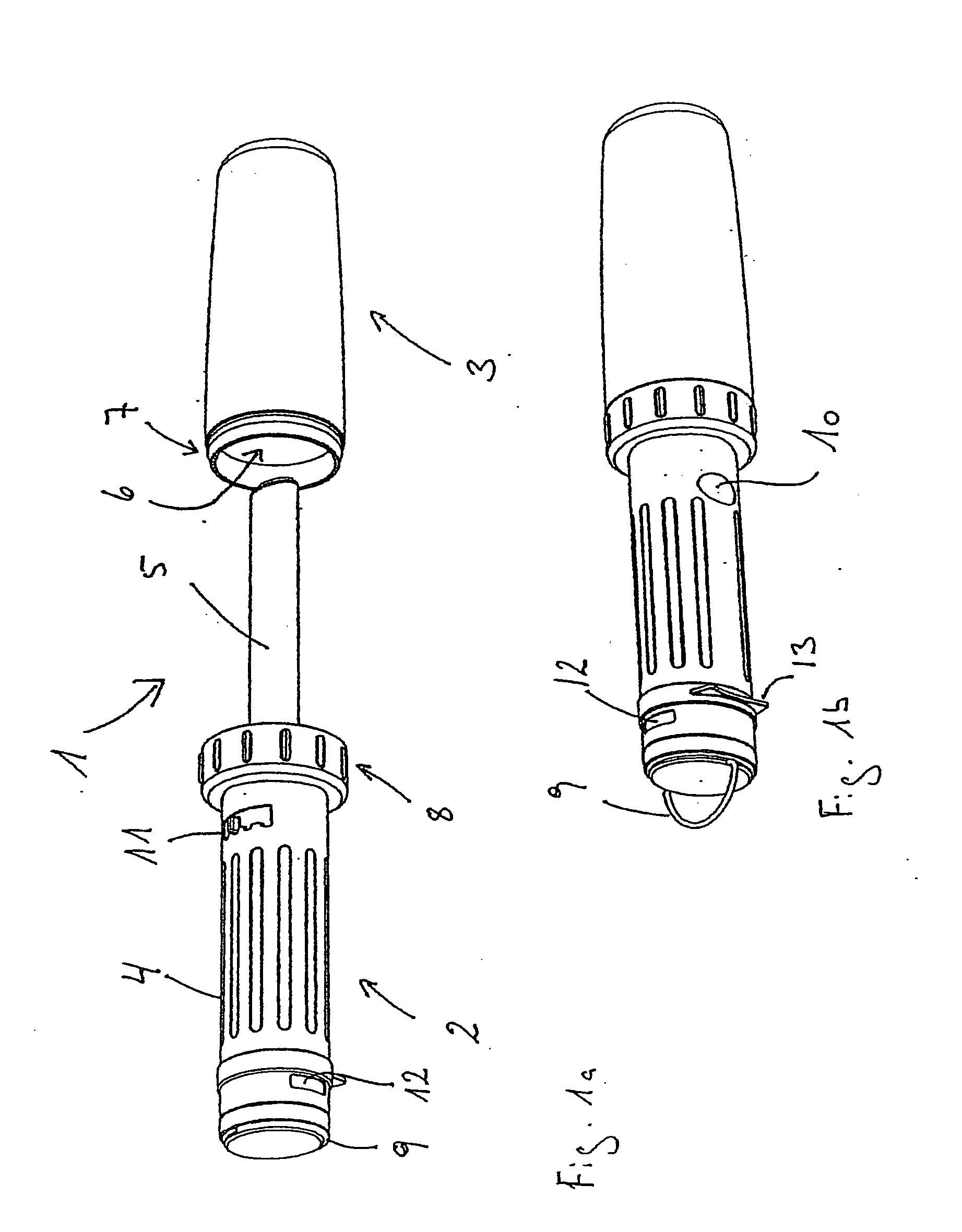

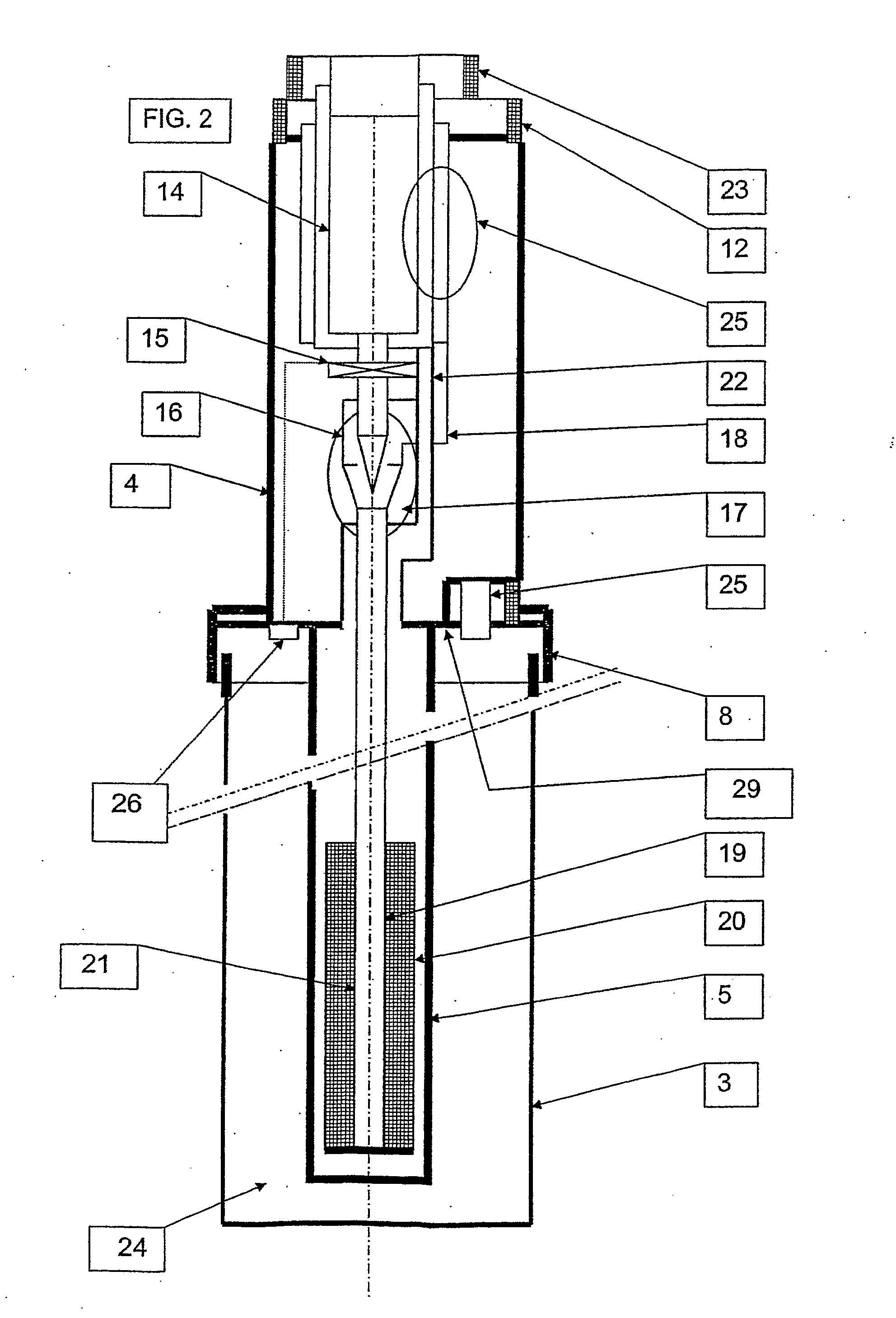

[0102]FIG. 1 shows a heating system 1 according to the invention. The heating system 1 comprises a heating unit 2 and a protecting container 163. The heating unit 2 has a handle 4 for attachment of the heating unit 2 and a heating pipe 5 that emits heat radiation from the catalytic element contained in the heating pipe 5. The heating pipe 5 can be fitted into a protective container 163, when the heating system is not in use. The container 163 may also be used for storing fluids or other materials such as powder, for example in connection with heating with the heating pipe 5 or in order to constitute a storage container of fluid or other materials during transport and use. The container 163 may be used for hot fluids and function as a thermo-isolating bottle or for warming hands by holding the container 163. The container 163 may be thermally isolated in order to reduce the output of energy to the surroundings.

[0103]The container 163 has an upper opening 6 and a thread 7 correspondin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com