Food container having an inner protecting layer

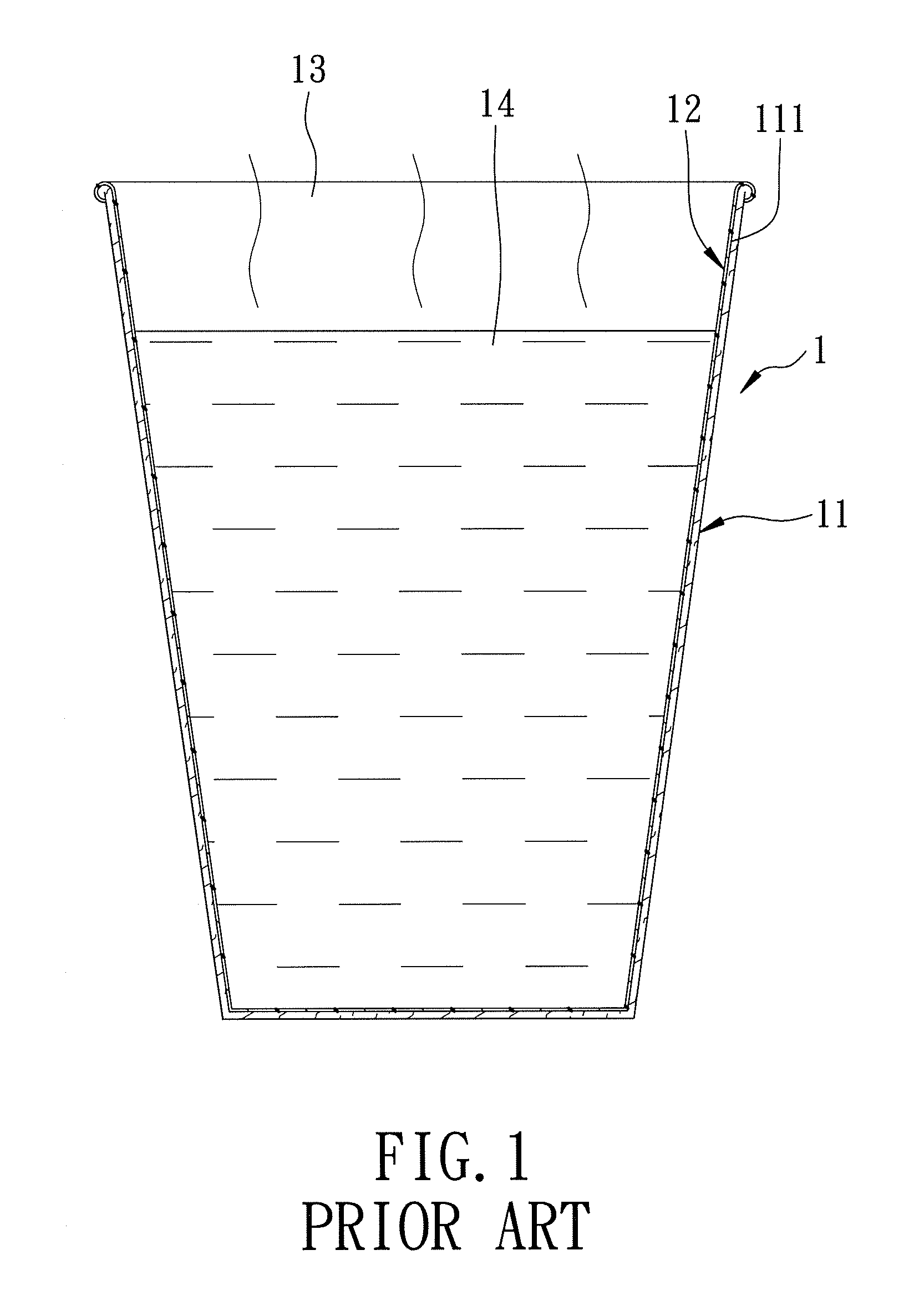

a protective layer and food container technology, applied in the field of food containers, can solve the problems of poor yield, liquid ingress into the paper cup, and damage to the paper cup,

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example

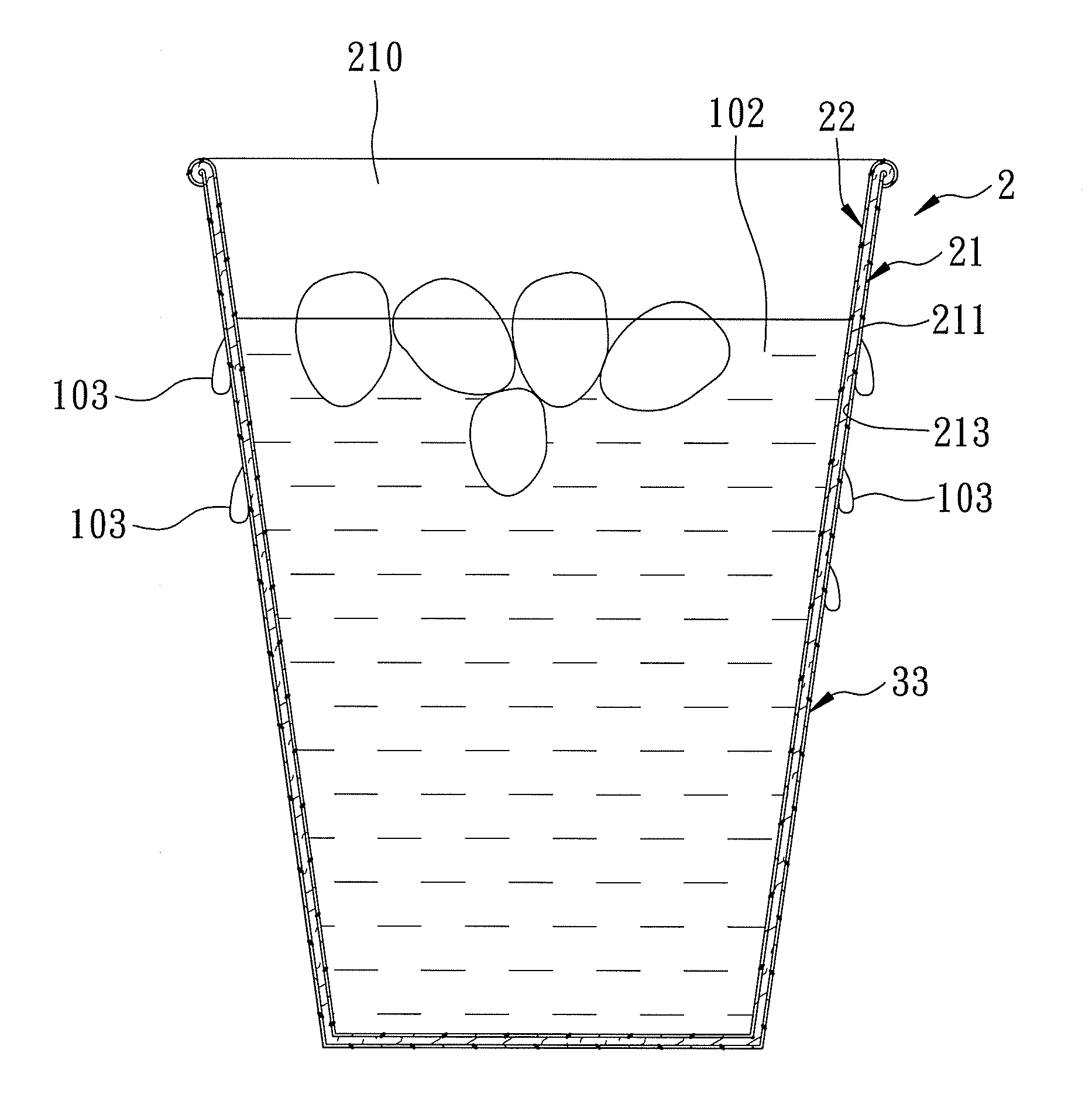

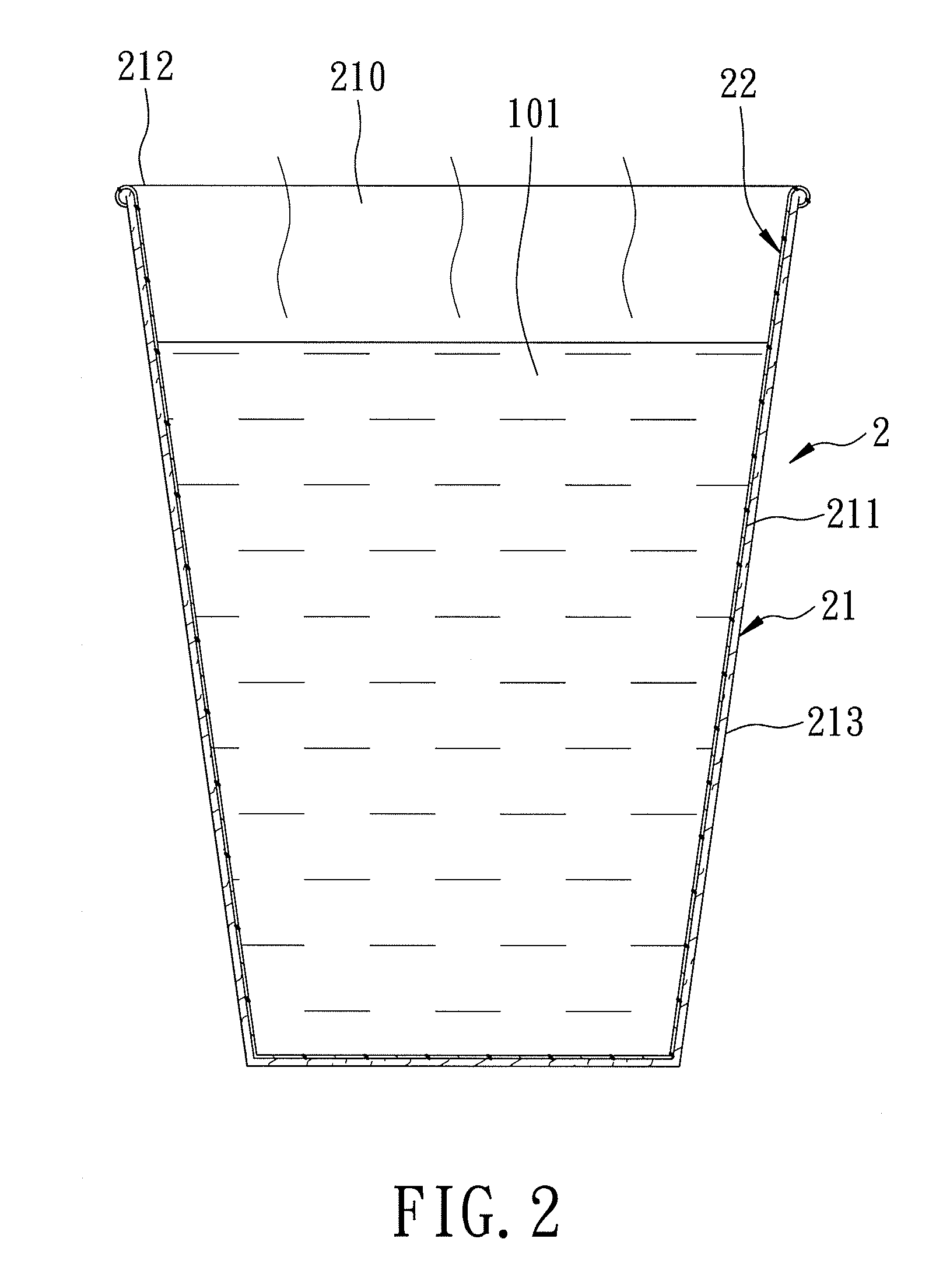

[0027]A biodegradable coating composition was prepared using only polybutylene succinate that was obtained from Mitsubishi Chemical Corporation (product models: GS pla, AZ91, AZ71, and AZ61). The biodegradable coating composition including 100 wt % polybutylene succinate was coated on the inner surface 211 of the container body 21 so as to form the inner protecting layer 22.

Test of Water-Proofing Property

[0028]The cup 2 was filled with hot liquid having a temperature of 95° C., and was left to stand for 24 hours. Leakage of the hot liquid from the receiving space 210 did not occur, which indicates that the inner protecting layer 22 has good water-proofing property and good heat resistance.

Test of Adhesion

[0029]Tests were conducted according to ASTM D4541. Two paper specimens having a size of 1.5 cm×10 cm were provided. One of the paper specimens was coated with 100 wt % polybutylene succinate so as to form a protecting layer thereon, and was is labeled as A. The other paper specimen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com