Acrylate color-stabilized phenolic bound abrasive products and methods for making same

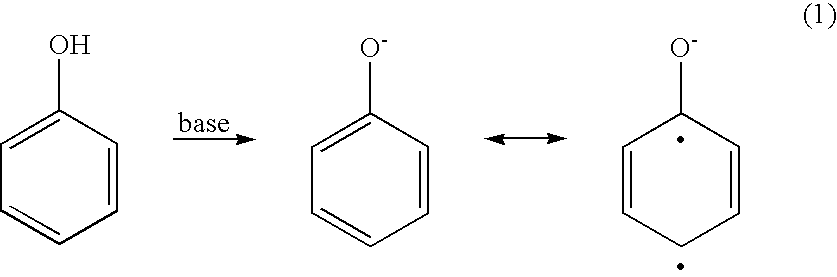

a technology of color-stabilized phenolics and acrylates, which is applied in the field of phenolic resin, can solve the problems of resin darkening problems that are particularly pronounced, unsatisfactory tendency to darken, and color variation within the product itsel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

[0059]Four phenolic resin compositions were formulated. Each composition contained the components shown in Table 2.

TABLE 2MaterialLBSPercentageResin PF Prefere 80-5080A21.020.9%Pigment Elcom Orange SK2.82.8%Nalco 2341 Defoamer0.10.1%Solmad Daxad 111.71.7%Solmod Cab-o-sil0.10.1%Filler Solvay Type A KBF464.564.3%TMPTA2.32.3%Water7.97.9%100.3100.0%

[0060]In addition, formulations 2-4 each contained the same amounts of a different acrylate. Table 3 below indicates the amount of acrylate present in each of the formulations.

TABLE 3Amount ofColor after curingType of acrylate added toacrylatefor 10 hrs @Trial No.phenolic resin formulationpresent250° F.1N / A0%black2Epoxy Acrylate (Ebecryl10%red3700)3Pentacrylate10%light brown-yellow4TMPTA10%light brown-yellow

[0061]The table shows that the compositions containing the acrylates were resistant to darkening upon exposure to heat during curing. In particular, pentacrylate and TMPTA were found to be the most effective in stabilizing the color of the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight fraction | aaaaa | aaaaa |

| weight fraction | aaaaa | aaaaa |

| weight fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com