Method for continuously fabricating silver nanowire

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

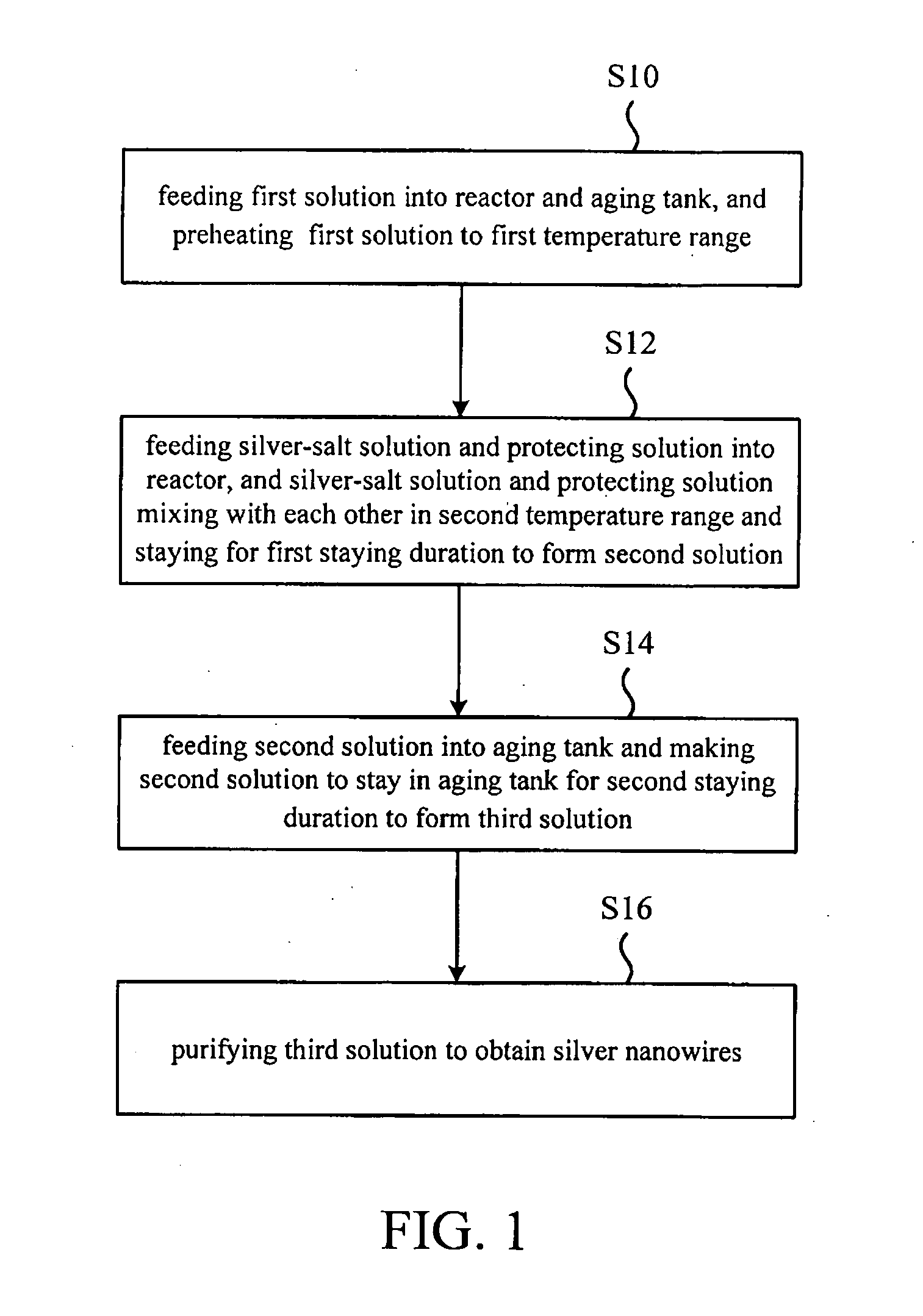

[0019]Please refer to FIG. 1. FIG. 1 is a flow chart illustrating the method for continuously fabricating silver nanowires according to an embodiment of the invention. As shown in FIG. 1, the method in the embodiment comprises the following steps of: in step S10, feeding a first solution into a reacting tank and a aging tank, and preheating the first solution to a first temperature range; in step S12, feeding a silver-salt solution and a protecting agent solution into the reacting tank, and the silver-salt solution and the protecting agent solution mixing with each other in a second temperature range and staying for a first staying duration to form a second solution; in step S14, feeding the second solution into the aging tank and making the second solution to stay in the aging tank for a second staying duration to form a third solution; in step S16, purifying the third solution to obtain the silver nanowires.

[0020]In this embodiment, the first solution could be a glycol solution, b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com