Heat transport device, electronic apparatus, and heat transport manufacturing method

a heat transport device and heat transport manufacturing technology, applied in semiconductor devices, cooling/ventilation/heating modifications, heating elements, etc., can solve the problems of heat transport device working fluid not flowing properly, heat transport is not performed properly, friction resistance and pressure loss are large, etc., to achieve convenient manufacturing, efficient heat transport, and high reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

[0045](Structure of Heat Spreader 1)

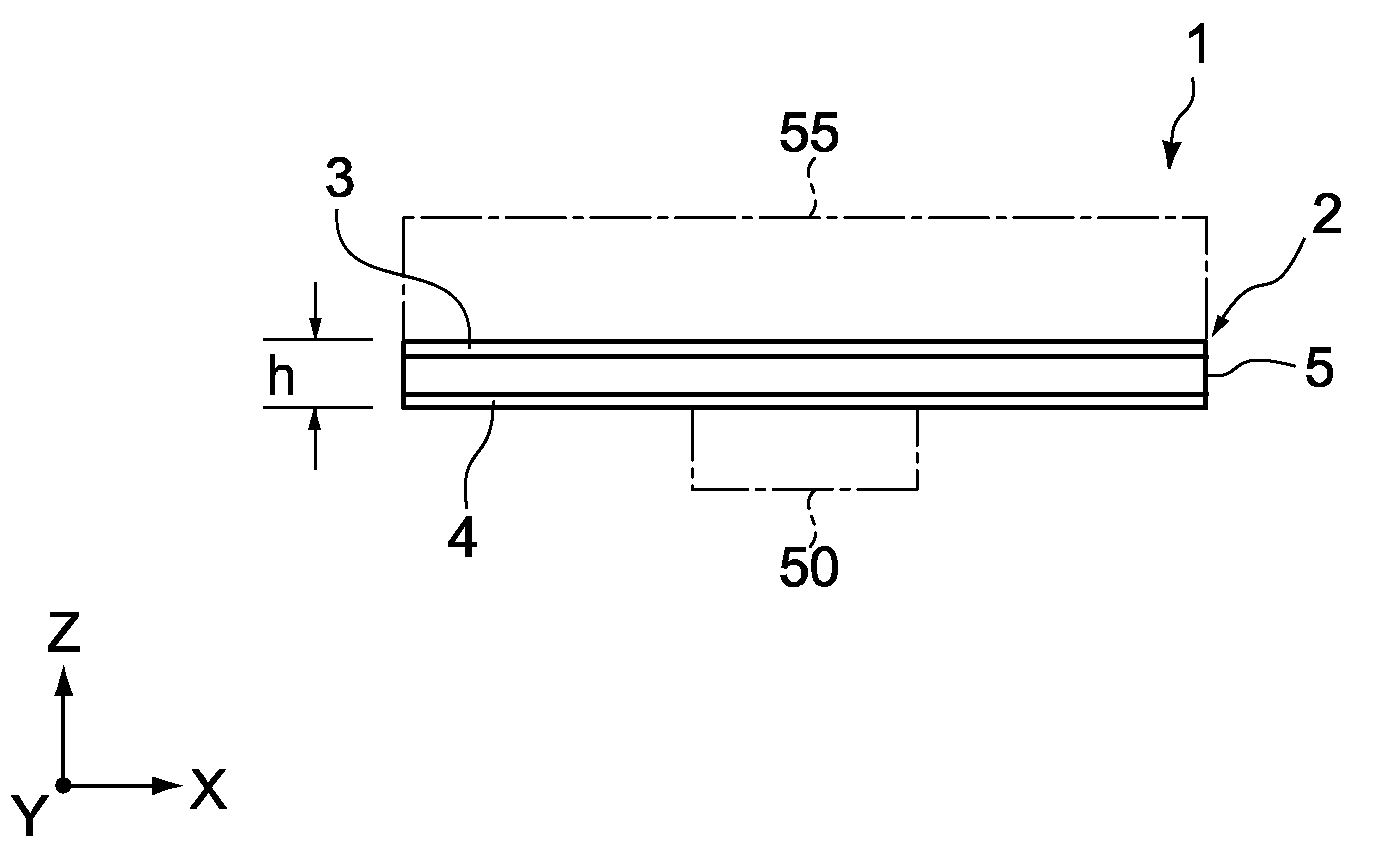

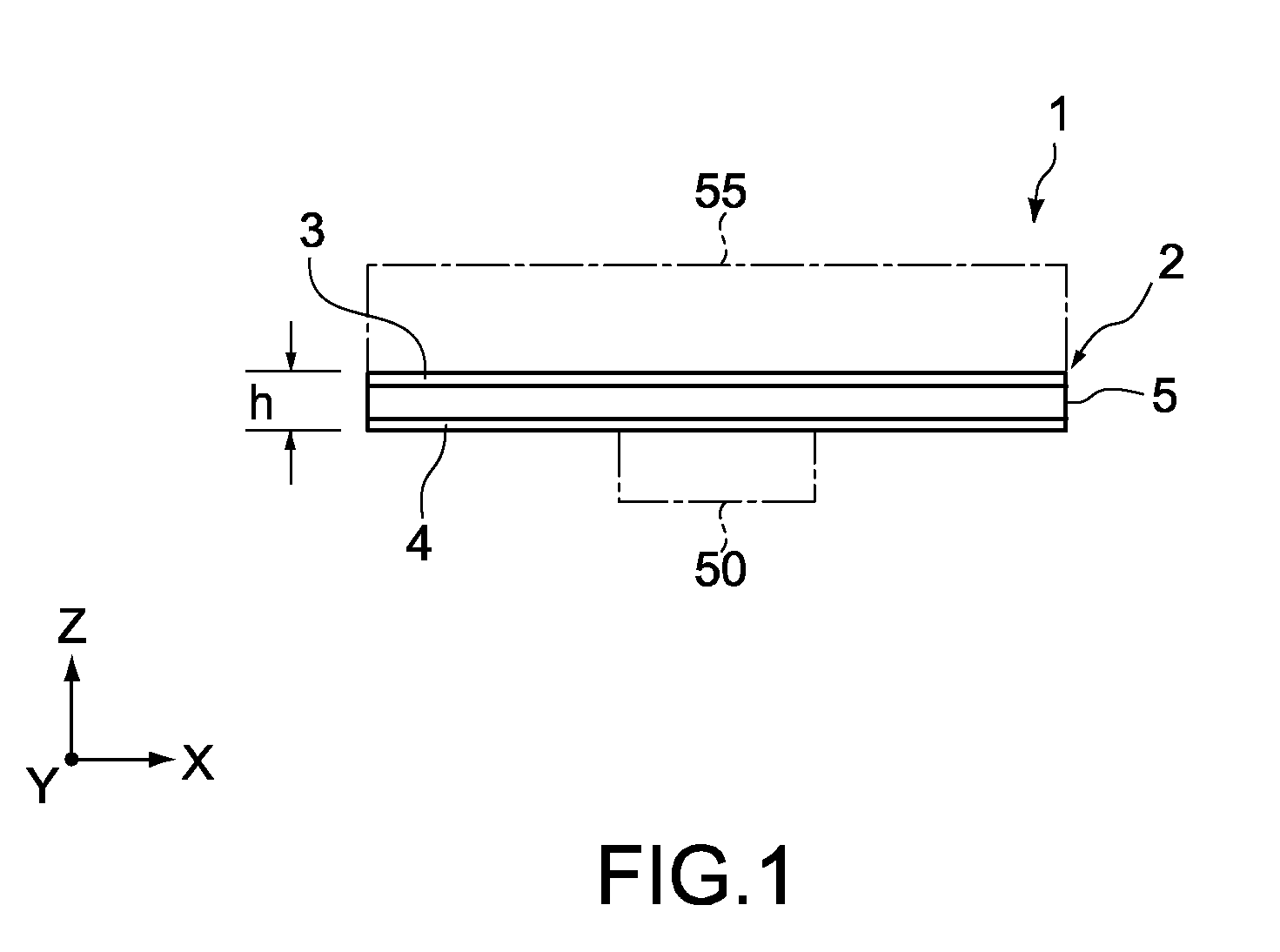

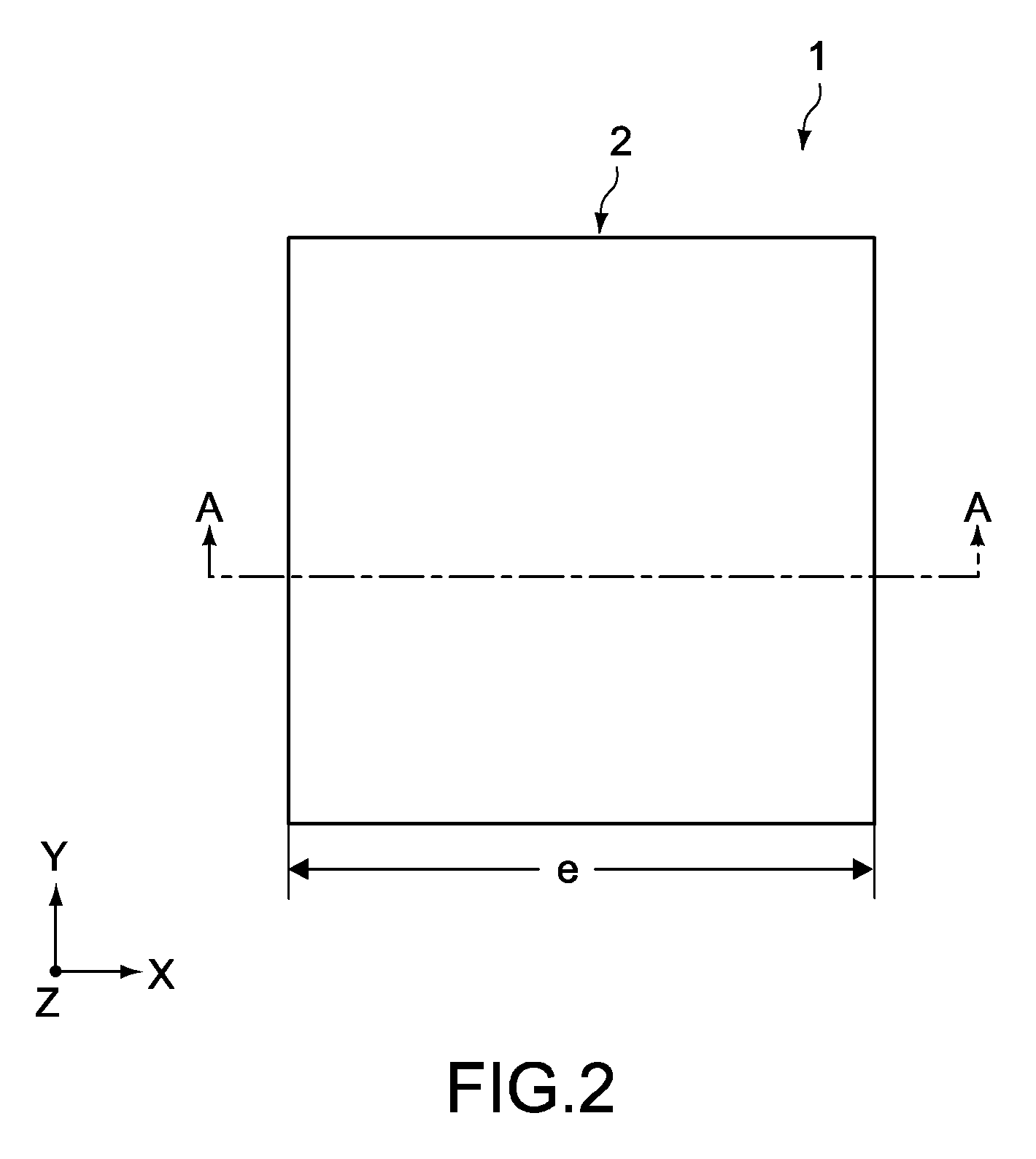

[0046]FIG. 1 is a side view showing a heat spreader 1 of a first embodiment of the present invention, the heat spreader being thermally connected to a heat source. FIG. 2 is a plan view showing the heat spreader 1 of FIG. 1.

[0047]As shown in FIGS. 1-2, the heat spreader 1 includes a container 2. The container 2 includes a heat reception plate 4 (first base member), a heat radiation plate 3, and sidewalls 5. The heat radiation plate 3 is provided so as to face the heat reception plate 4. The sidewalls 5 tightly bond the heat reception plate 4 and the heat radiation plate 3.

[0048]The heat radiation plate 3, the heat reception plate 4, and the sidewalls 5 may be bonded by brazing, that is, welded, or may be bonded with an adhesive material depending on the materials. The heat radiation plate 3, the heat reception plate 4, and the sidewalls 5 are made of a metal material, for example. The metal material is for example, copper having a high thermal con...

second embodiment

Structure of Heat Spreader 11

[0105]FIG. 11 is a sectional view showing a heat spreader 11 according to a second embodiment of the present invention.

[0106]Hereinafter, components, functions, and the like similar to those of the heat spreader 1 of the first embodiment will be attached with similar reference symbols, the description will be simplified or omitted, and different part will mainly be described.

[0107]The heat spreader 11 includes a container 12. The container 12 includes a heat reception plate 14, a heat radiation plate 13, and sidewalls 15. The heat radiation plate 13 is provided so as to face the heat reception plate 14. The sidewalls 15 tightly bond the heat reception plate 14 and the heat radiation plate 13. The container 12 further includes a refrigerant sealed therein. An inner space of the container 12 mainly serves as a flow path 16 for the refrigerant.

[0108]The heat reception plate 14 includes a heat reception surface 141, an evaporation surface 142, and a bond are...

third embodiment

Structure of Heat Spreader 21

[0124]FIG. 14 is an exploded perspective view of a heat spreader 21 according to a third embodiment of the present invention.

[0125]The heat spreader 21 includes a container 22. The container 22 includes a heat reception plate 24, a heat radiation plate 23, and bond areas 281 of a plurality of flow path plate members 28. The heat radiation plate 23 is provided so as to face the heat reception plate 24. The container 22 further includes a refrigerant sealed therein.

[0126]The heat reception plate 24 has a structure same as the structure of the heat reception plate 4. The heat reception plate 24 includes a heat reception surface 241, an evaporation surface 242, and a bond area 243.

[0127]The bond area 243 is bonded to the bond areas 281 of the plurality of flow path plate members 28.

[0128]An evaporation portion 27 having a structure same as the evaporation portion 7 is provided on the evaporation surface 242.

[0129]A heat source is thermally connected to the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com