One-pack type epoxy resin composition and use thereof

a technology of epoxy resin and composition, applied in the direction of synthetic resin layered products, electromagnetic relay details, solid-state devices, etc., can solve the problems of insufficient heat resistance of cured products, unreacted substances remaining, poor air tightness, etc., to accelerate curing, accelerate curing, and accelerate curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

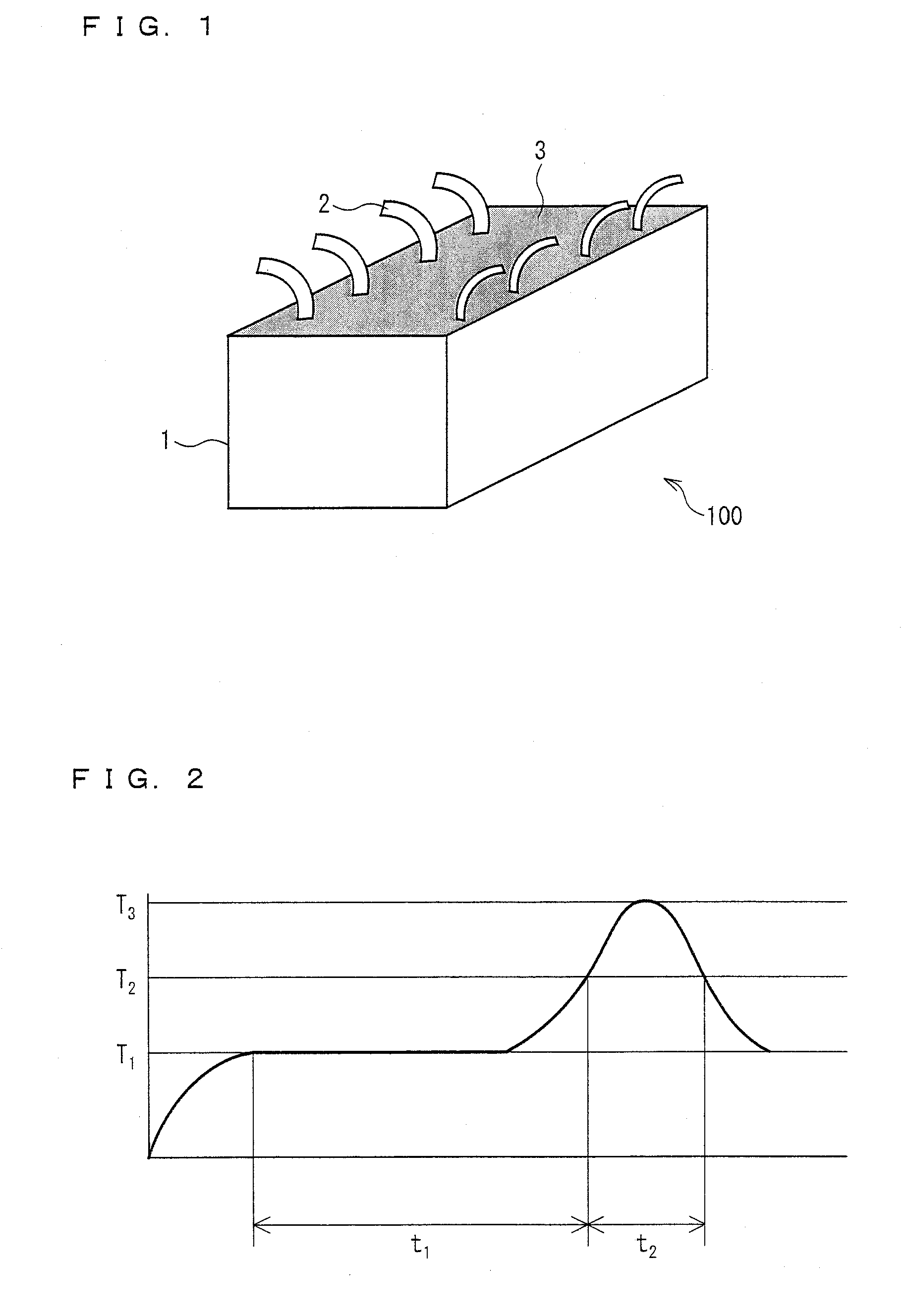

Image

Examples

example 1

[0133]A one-pack type epoxy resin composition was prepared by mixing, with respect to 100 parts by weight of bisphenol-A diglycidylether [in Table 1, denoted as “Epoxy Resin (A)”] serving as an epoxy resin, the following curing agents: 10 parts by weight of dicyandiamide [in Table 1, denoted as “Curing Agent (B)”]; 10 parts by weight of an epoxy resin adduct compound (product name: AMICURE (Registered Trademark) MY-24, available from Ajinomoto Fine-Techno Co., Inc.) [in Table 1, denoted as “Curing Agent (C)”]; and 10 parts by weight of 1-cyanoethyl-2-undecylimidazoliumtrimellitate [in Table 1, denoted as “Curing Agent (D)”]. The resultant mixture was further mixed with (i) 1 part by weight of pH 8.0 carbon black (product name: #25, available from Mitsubishi Chemical Corporation) [in Table 1, denoted as “Carbon Black (F)”], (ii) 1 part by weight of an untreated silica (product name: Aerosil 200, available from Nippon Aerosil Co., Ltd.) [in Table 1, denoted as “Inorganic Filler (G)”] ...

examples 2 to 8

, Comparative Examples 1 to 7

[0137]As shown in Table 1, in each of Examples 2 to 4, a curing agent different from that used in Example 1 was used as Curing Agent (D), and an airtightness evaluation test was conducted in the same manner as in Example 1.

[0138]As shown in Table 1, in Example 5, with respect to 50 parts by weight of bisphenol-A diglycidylether, 50 parts by weight of glycerin diglycidylether [in Table 1, denoted as “Wettability Enhancer (E)”] was added. Further, in Example 5, with respect to a total amount (100 parts by weight) of bisphenol-A diglycidylether and glycerin diglycidylether, the same Curing Agents (B) to (D), carbon black, untreated silica, and calcium carbonate as those used in Example 1 were added in the same amounts as those in Example 1, and an airtightness evaluation test was conducted in the same manner as in Example 1.

[0139]As shown in Table 1, in Example 6, pH 3.0 (different from that in Example 1) carbon black (product name: MA11, available from Mit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com