Continuous micro anode guided electroplating device and method thereof

a technology of micro anodes and electroplating devices, which is applied in the direction of electrodes, electrolysis components, cells, etc., can solve the problems of inability to mill, welding and fasten conventional mechanical devices to achieve the space resolution required by microelements, and inability to achieve optimal performance of thickness structures with low aspect ratios. to achieve the effect of reducing the contamination of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

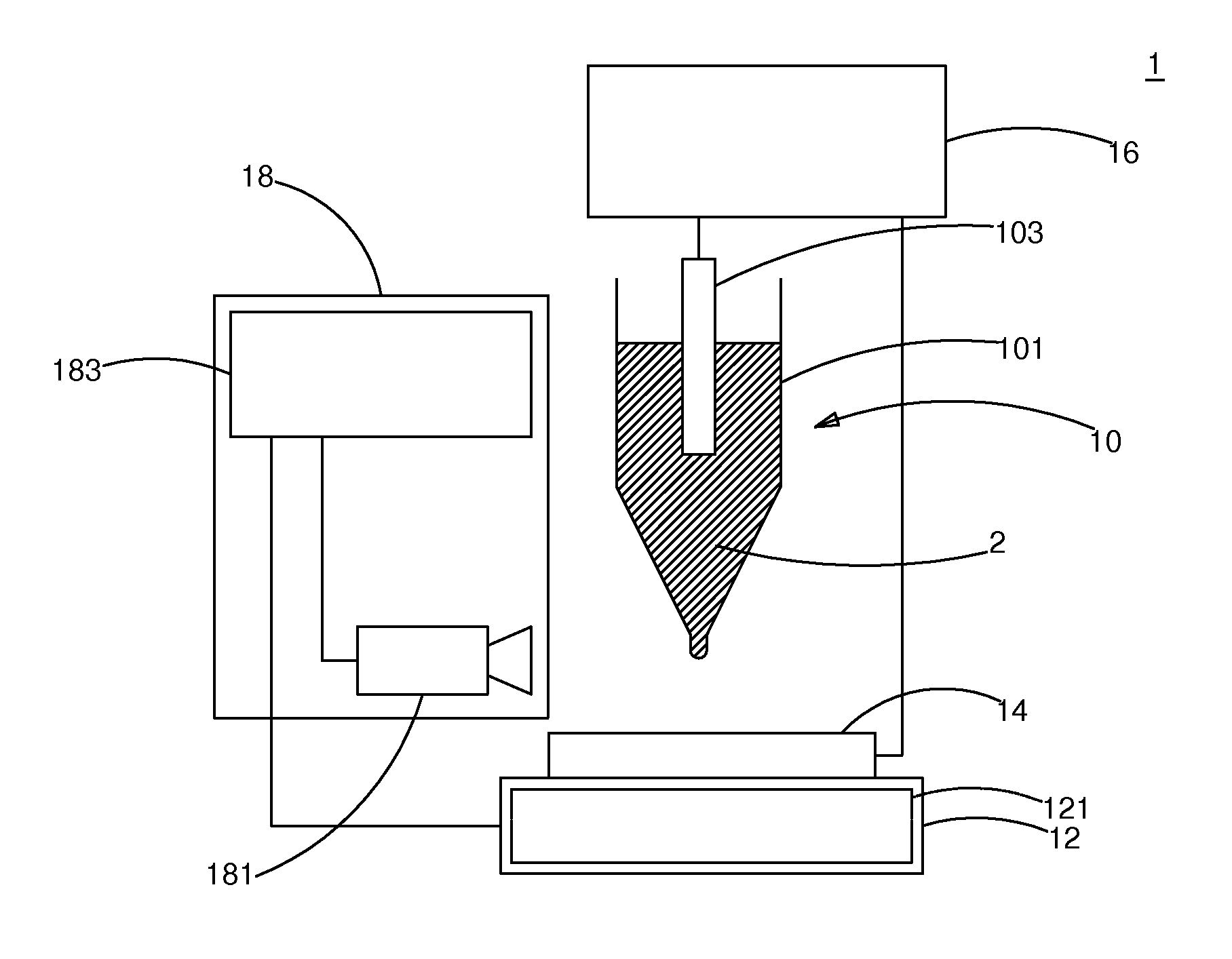

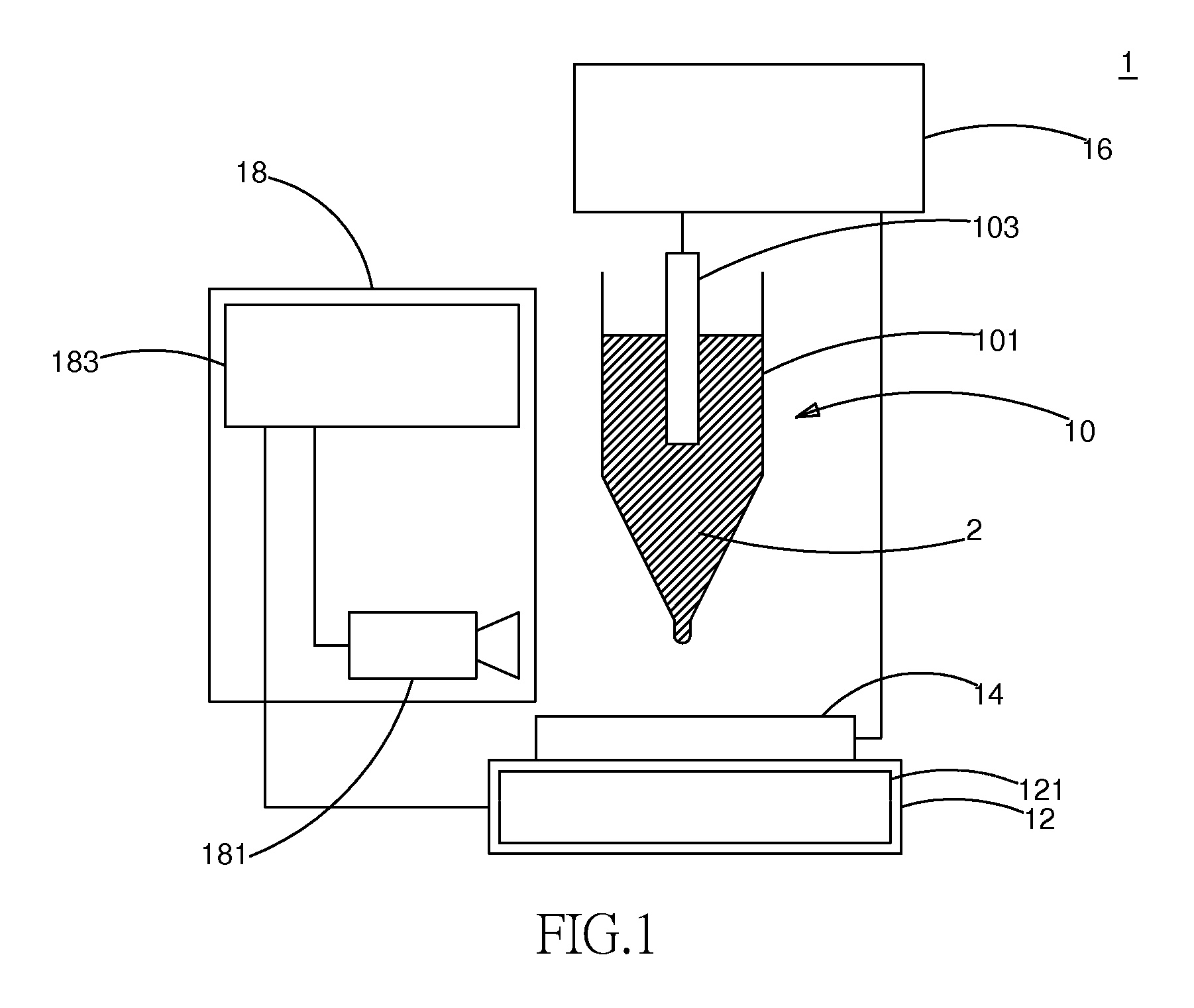

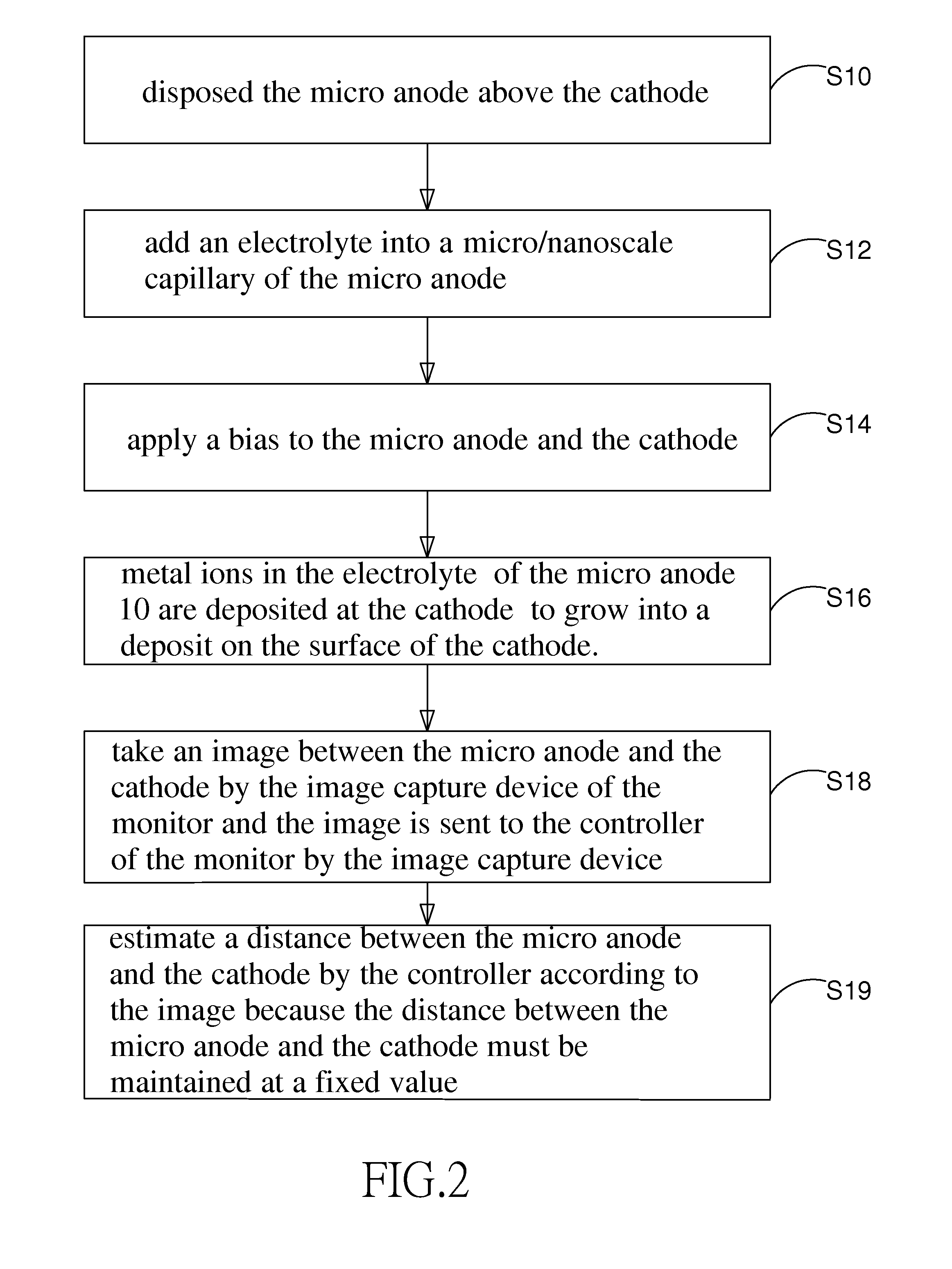

[0017]Refer to FIG. 1, a continuous micro anode guided electroplating device 1 includes a micro anode 1, a loading platform 12, a cathode 14, a power supply 16 and a monitor 18. The micro anode 10 consists of a micro / nanoscale capillary 101 and a conductor 103. The conductor 103 is made from platinum and is disposed inside the capillary 101 that is filled with an electrolyte (electroplating solution) 2. The loading platform 12 is set under the micro anode 10 and is having a driving device 121 therein. The driving device 121 drives the loading platform 12 to move. In this embodiment, the driving device 121 is a motor. The cathode 14 is a workpiece that is put on the loading platform 12 for electroplating. The power supply 16 is composed of an anode and a cathode. The anode of the power supply 16 is connected to the micro anode 10 and the cathode of the power supply 16 is connected to the cathode 14. The power supply 16 supplies a bias to the micro anode 10 and the cathode 14 so that ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| distance | aaaaa | aaaaa |

| distance | aaaaa | aaaaa |

| conductor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com