Synthesis of nanostructured photoactive films with controlled morphology by a flame aerosol reactor

a technology of nanostructured photoactive films and flame aerosols, which is applied in the direction of catalyst activation/preparation, electrolytic capacitors, physical/chemical process catalysts, etc., can solve the problems of high production cost of silicon-based solar cells, difficult control of metal species particle size and nanostructured morphology, and methods that are not well suited to inexpensive industrial scaleup, etc., to improve nanostructured photo-watersplitting cells, improve nanostructured p/n junction solar cells

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 1

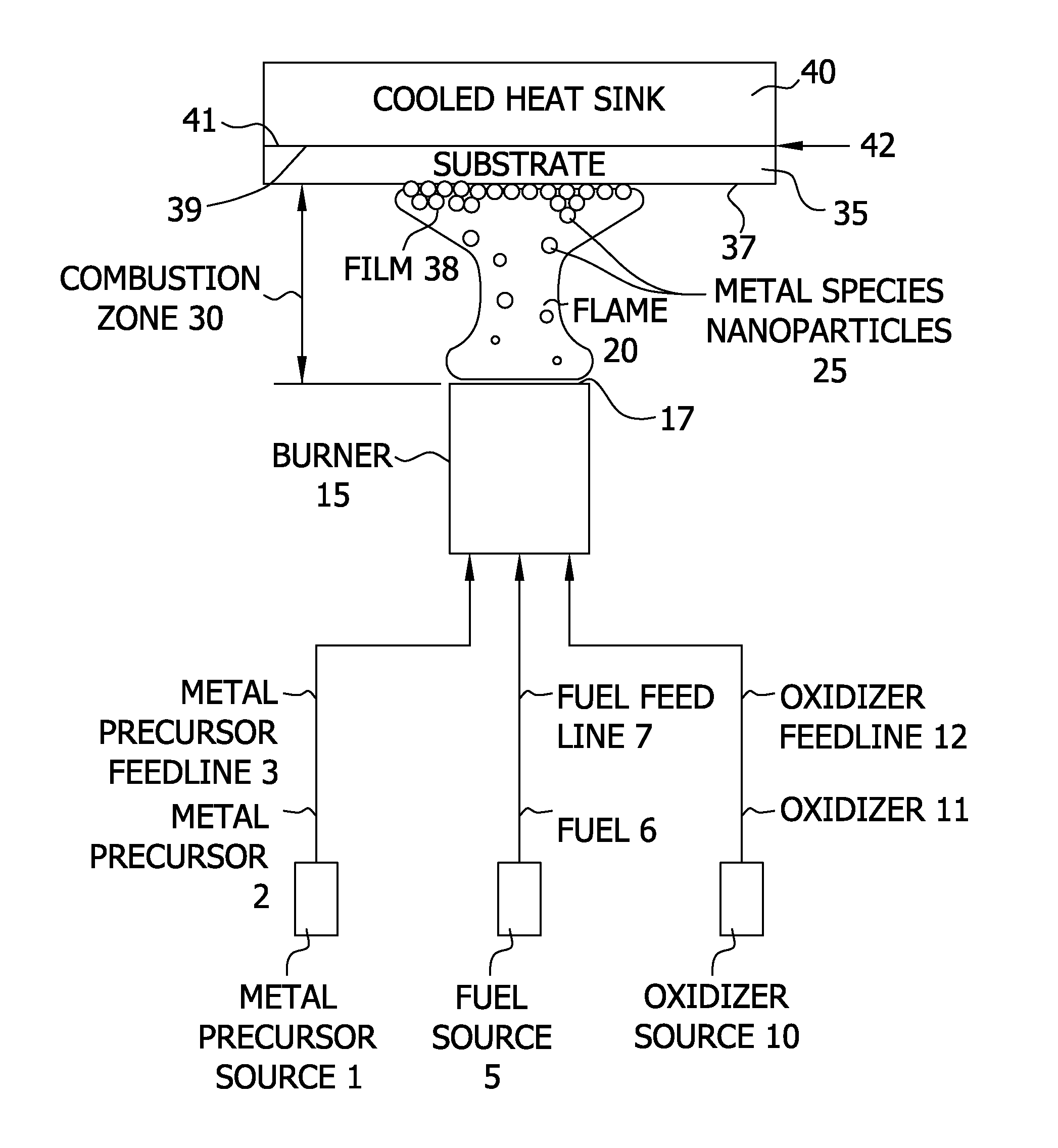

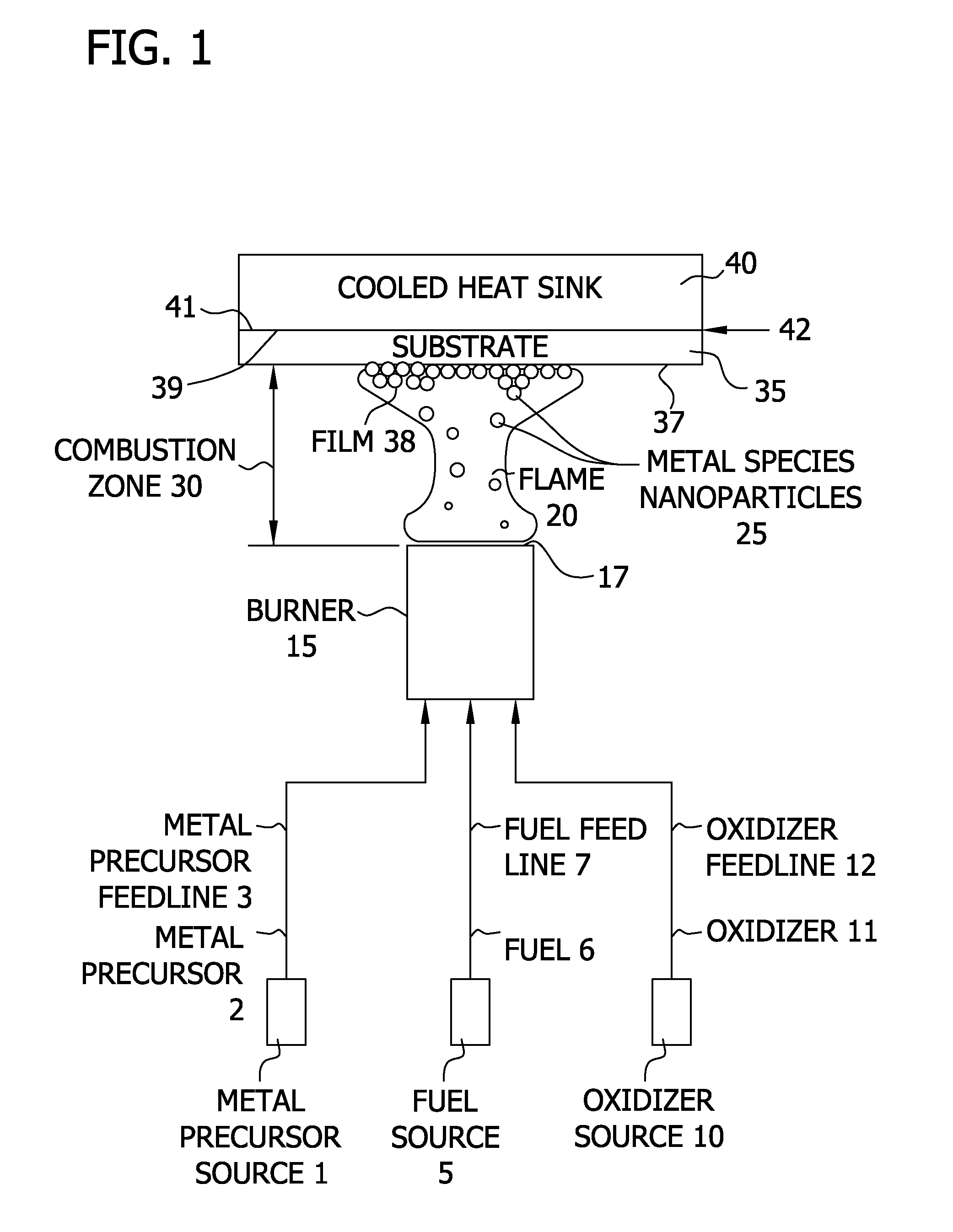

[0078]The experimental apparatus comprised a precursor feed system, a FLAR and a temperature controlled deposition substrate as generally depicted in FIG. 1. The precursor feed system comprised a bubbler containing titanium isopropoxide (TTIP, Aldrich: 205273, 97% purity) through which argon (Grade 4.8) was bubbled at varying flow rates. The temperature of the bubbler was maintained at 30° C. To prevent condensation of the TTIP, the lines leading up to the flame reactor were heated to approximately 50° C. The TTIP feed rate was calculated based on the saturation pressure and was assumed to be proportional to the argon flow rate through the bubbler. An additional argon line was added so the total argon flow rate could be held constant at 2.0 Lpm (liters per minute at STP) while varying the flow through the bubbler. The FLAR was a premixed methane-oxygen burner made of a 0.95 cm (⅜ inch) O.D. stainless steel tube into which was placed three 0.32 cm (⅛ inch) tubes designed to achieve a...

example 2

[0096]A FLAR was used to synthesize TiO2 films with controlled morphology and thickness to evaluate the optoelectronic properties of watersplitting and photovoltaic performance. A FLAR was assembled comprising a precursor feed system, premixed methane-oxygen flame and a water-cooled deposition substrate (FIG. 23). The FLAR had digital mass flow controllers (MKS, Wilmington Mass.) to control the processes gases methane, oxygen, dilution-argon and carrier-argon. TTIP (Aldrich: 205273, 97% pure), was used to synthesize TiO2 in the gas-phase. The precursor was delivered to the flame region by passing carrier-argon through a homemade bubbler that was maintained at 37° C. The carrier-argon flow rate was kept constant at 2.0 Lpm (at STP), which corresponded to a TTIP feed rate of approximately 1.2 mmol / hr, based on the vapor pressure of TTIP. The methane, oxygen and dilution-argon flow rates were kept constant at 0.9, 2.7 and 2.0 Lpm, respectively. All 4 process gasses were combined and se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com