Anti-reflection sheet, display element and display device

a technology of display elements and anti-reflection sheets, applied in the direction of identification means, instruments, coatings, etc., can solve the problems of easy wear and tear of pyramid-shaped or conic projections, easy to see images, and easy to fall off, so as to improve the wear resistance and pressure resistance of projections without lowering optical properties, the effect of low haze value and low reflectan

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

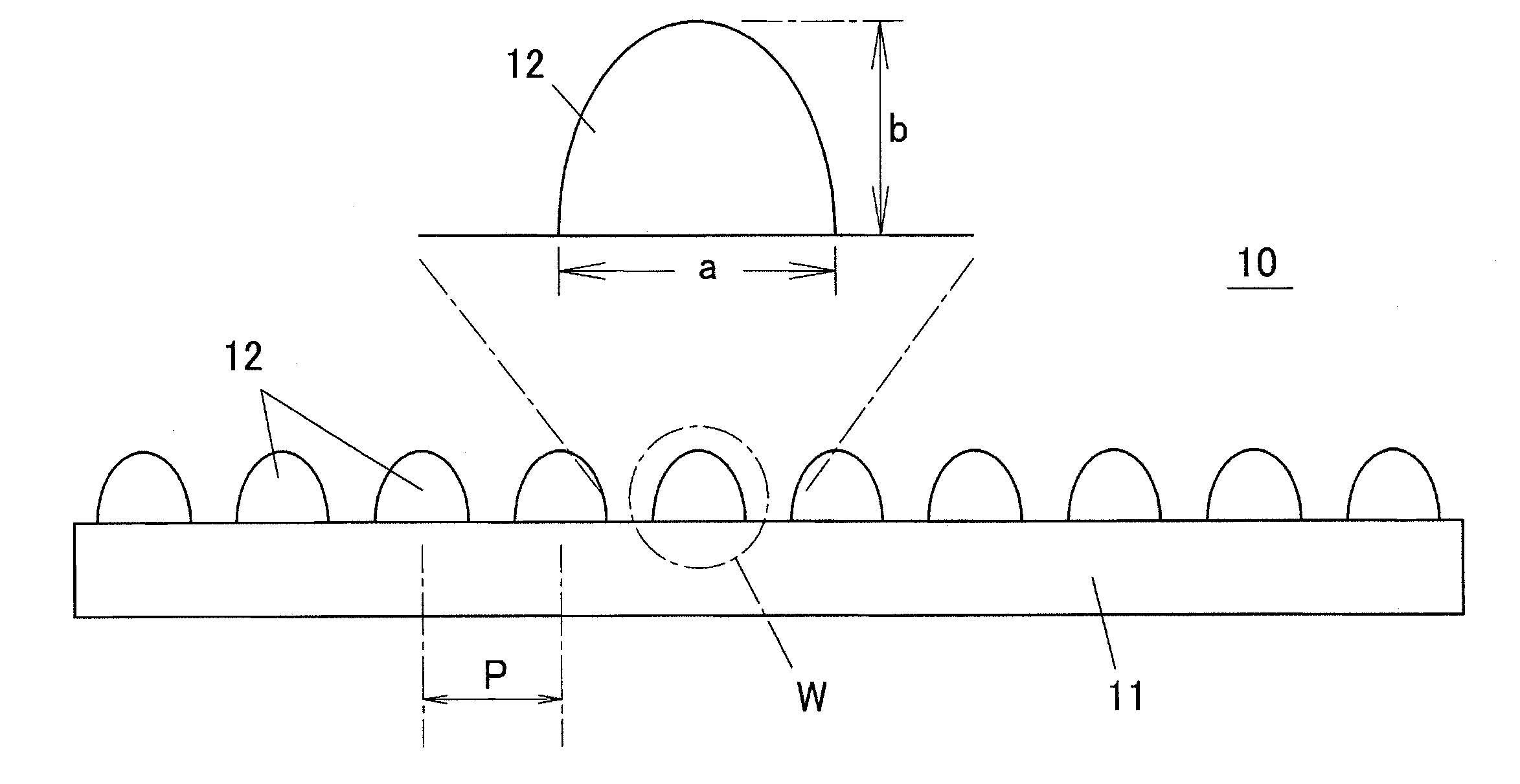

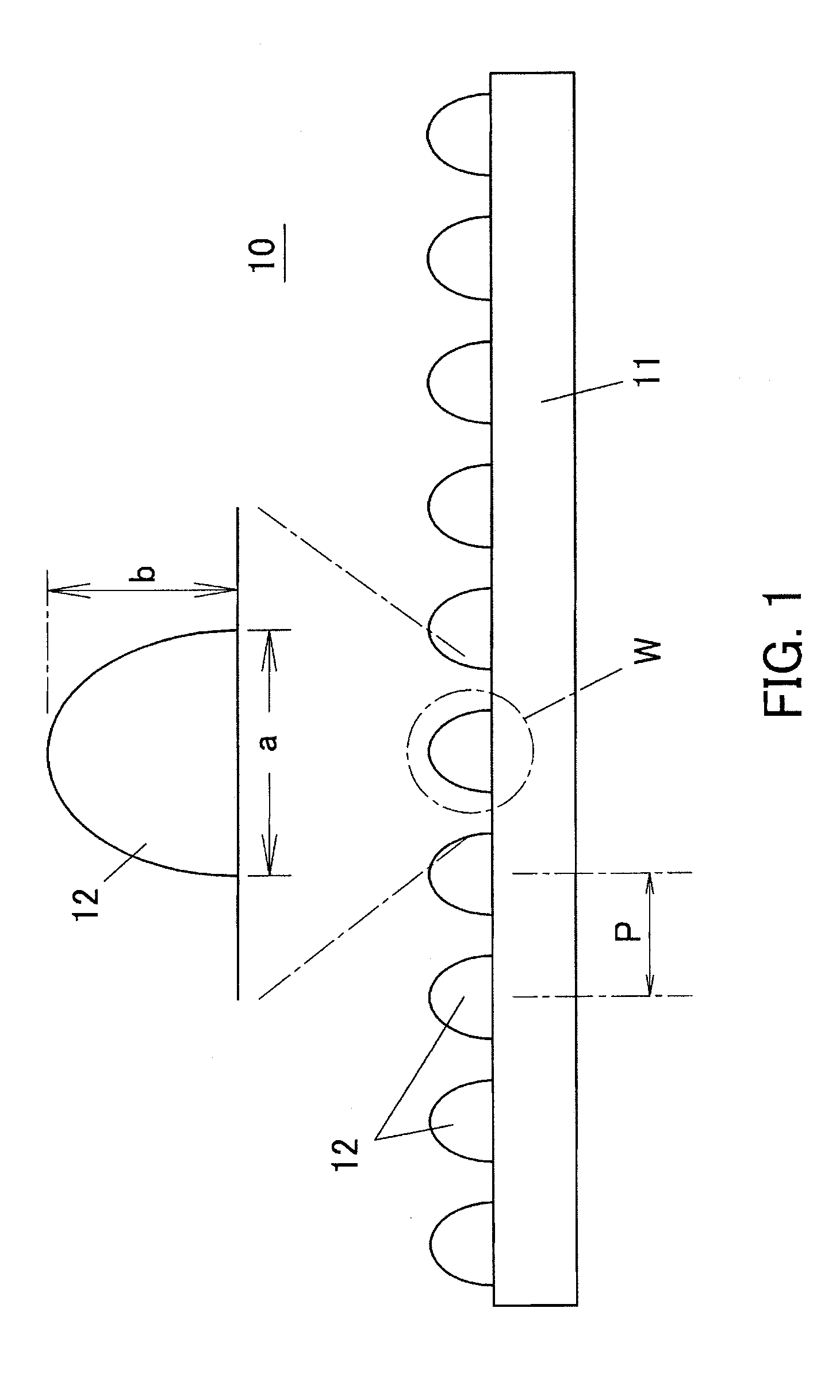

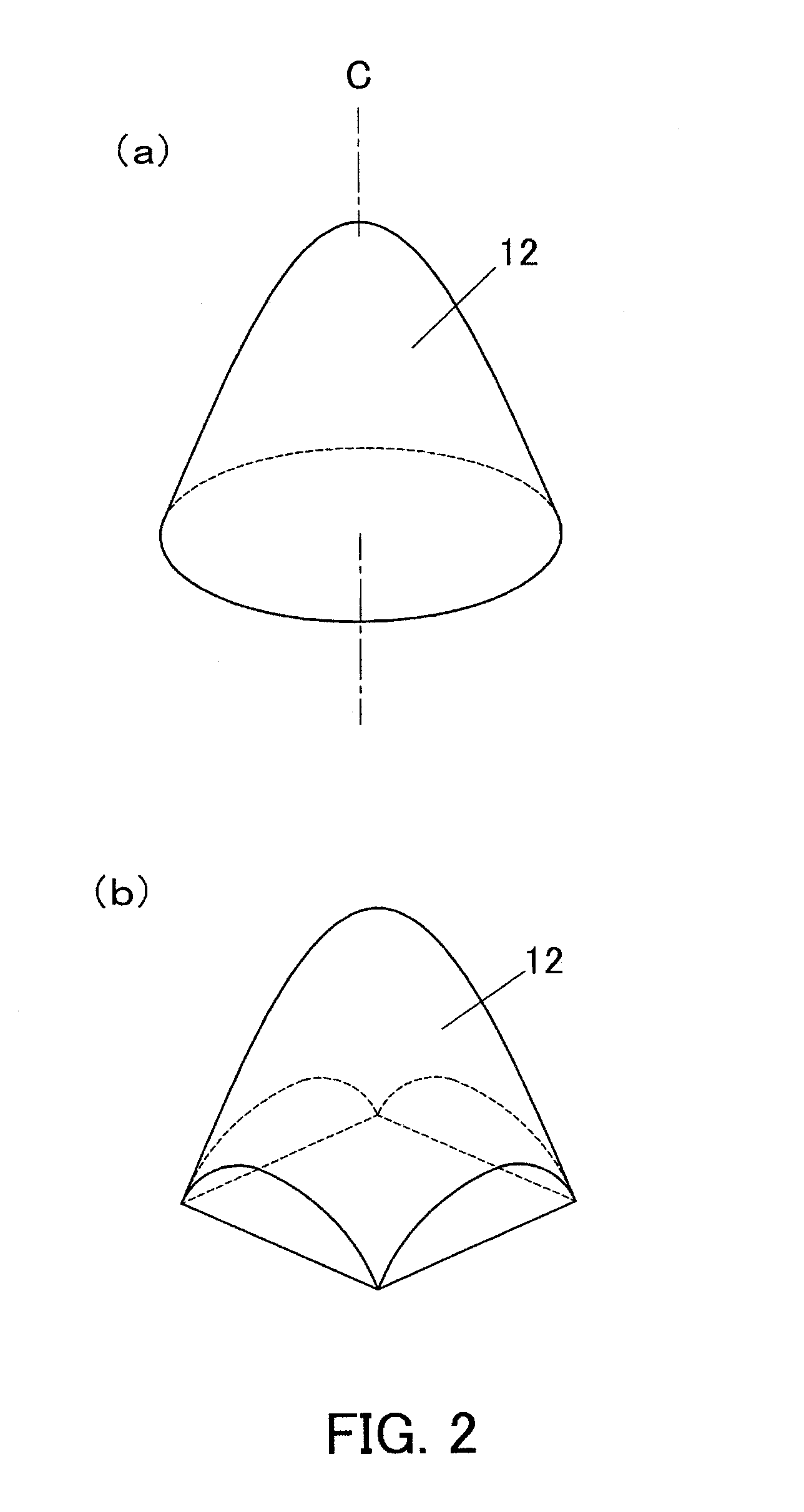

[0061]FIG. 1 is a schematic cross sectional view showing an anti-reflection sheet according to a first embodiment of the present invention, and FIG. 1 further shows an enlarged W portion thereof. FIG. 2(a) is a perspective view showing one shape of a projection provided on a surface of the anti-reflection sheet, and FIG. 2(b) is a perspective view showing another shape of the projection. FIG. 3(a) is a schematic plan view showing one example of arrangement of projections on a surface of a substrate, FIG. 3(b) is a schematic plan view showing another example of the arrangement of the projections, and FIG. 3(c) is a schematic plan view showing still another example of the arrangement of the projections.

[0062]As shown in FIG. 1, an anti-reflection sheet 10 is formed in a manner of bringing many transparent fine projections 12 (resin layer composed of only projections) into close formation on a flat and smooth surface of a transparent substrate 11. However, the projection 12 is shown ex...

second embodiment

[0092]FIG. 14 shows a shape of a cross section of a projection 12 used for an anti-reflection sheet according to a second embodiment of the present invention. The shape of the cross section of the projection 12 is in the shape of the quadratic function (parabola) in the first embodiment. However, in the second embodiment, a tip of the projection 12 is slightly wider than that of the quadratic function and wear-resistance and pressure resistance are higher than those of the projection 12 in the first embodiment.

[0093]As shown in this example, the cross section of the projection 12 is permitted to have a shape that the quadratic function shape is slightly deformed. Deformation is permitted so long as the wear-resistance and pressure-resistance of the projection 12 are not impaired, and a correlation coefficient R of the projection 12 may be 0.8 or more (the correlation coefficient R of the quadratic function itself is 1).

[0094]The correlation coefficient R of the shape of the cross se...

third embodiment

[0097]FIG. 16 is an explanatory view of a third embodiment of the present invention, and shows a cross section of a recess 16 having a quadratic function-shaped cross section. Although the anti-reflection sheet is adopted in the first embodiment in which the projections are formed on the substrate 11, also an anti-reflection sheet according to the third embodiment may be adopted in which the fine recesses 16 each having the quadratic functions-shaped cross section (rotational paraboloid) are closely formed. The aspect ratio and the other conditions of the projection 12 described in the first embodiment are also applied to the recess 16.

[0098]Also in the anti-reflection sheet in which the recesses 16 are formed, reflection of light can be suppressed similar to the anti-reflection sheet 10 in which the projections 12 are formed. When the recesses 16 are arranged at certain intervals, there is no possibility that the recess 16 is worn down and crushed compared with the projection 12. H...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fraction | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com