Temporary floating breakwater and causeway with simulated beach and kelp

a technology of causeway and temporary breakwater, which is applied in the direction of special-purpose vessels, vessel construction, groynes, etc., can solve the problems of inability to achieve the approach, the construction of conventional breakwaters is labor-intensive, and the approach is simply not feasible, so as to achieve the effect of sufficient size and suitable characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

Main Tube and FBW Floats

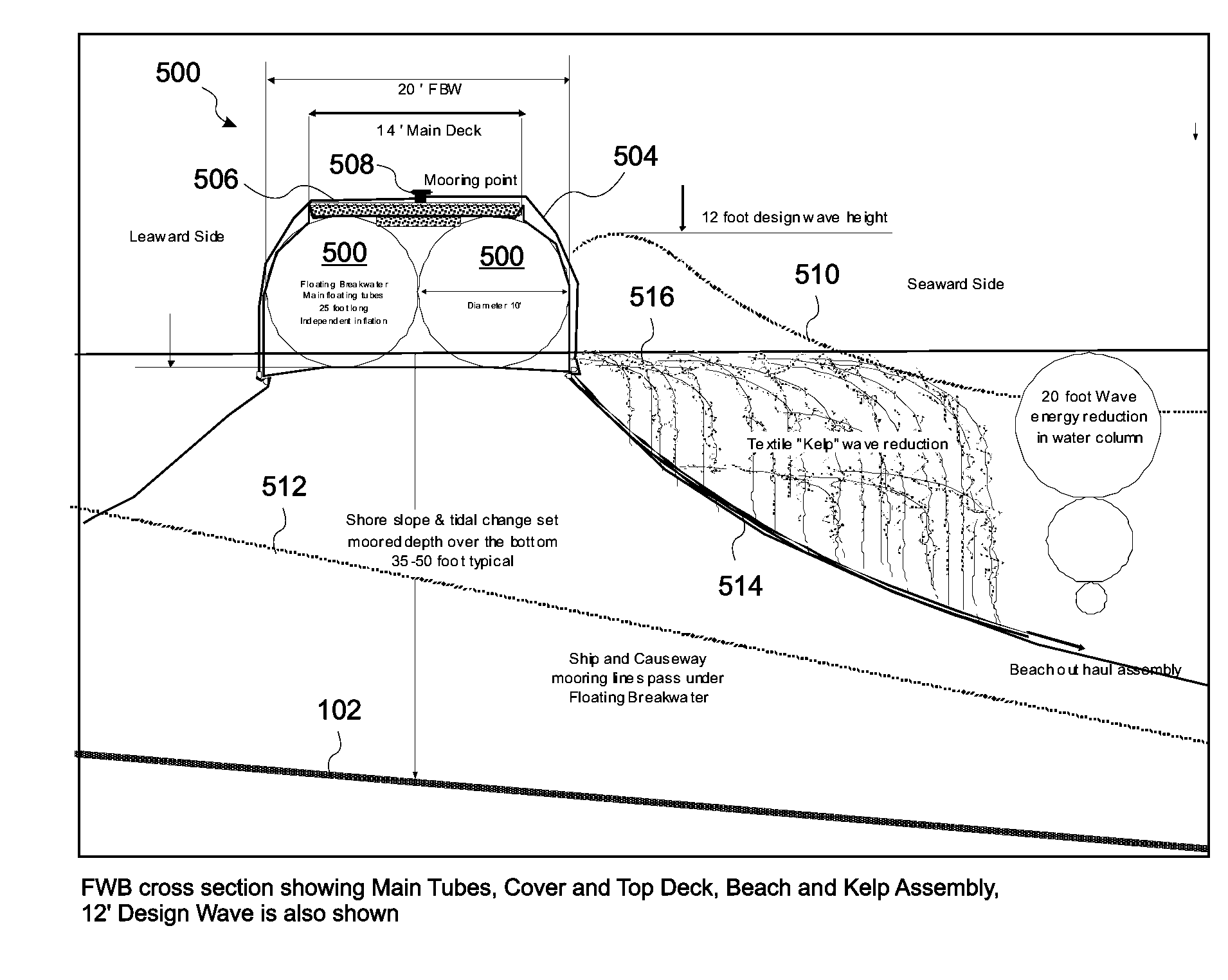

[0038]FIG. 5 is a cross sectional view of an embodiment of the present invention in which an inflatable floating breakwater (“FBW”) 500 is deployed at 300 feet. The total packed volume of the inflatable portion of this 300′ system as shown in the cross section of FIG. 5 can be packed in a single 20′ ISO container. The elimination of mechanical joints between inflated sections is a major feature of this approach, since hinges with solid pivot points are large, heavy, and prone to failure from wave action on a FBW. The embodiment of FIG. 5 also provides redundant flotation chambers 502 by enclosing a plurality of standard 10×25 ft floats 502 within a continuous cover layer 504. The cover layer 504 protects the inflated floats 502 and forms a textile flex point in the structure. This arrangement permits buckling of the assembly under extreme loads without damage. By staggering the float elements 502 in a second tube assembly 504 (i.e. the continuous cover layer)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com