Method and device for machining a part by abrasion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

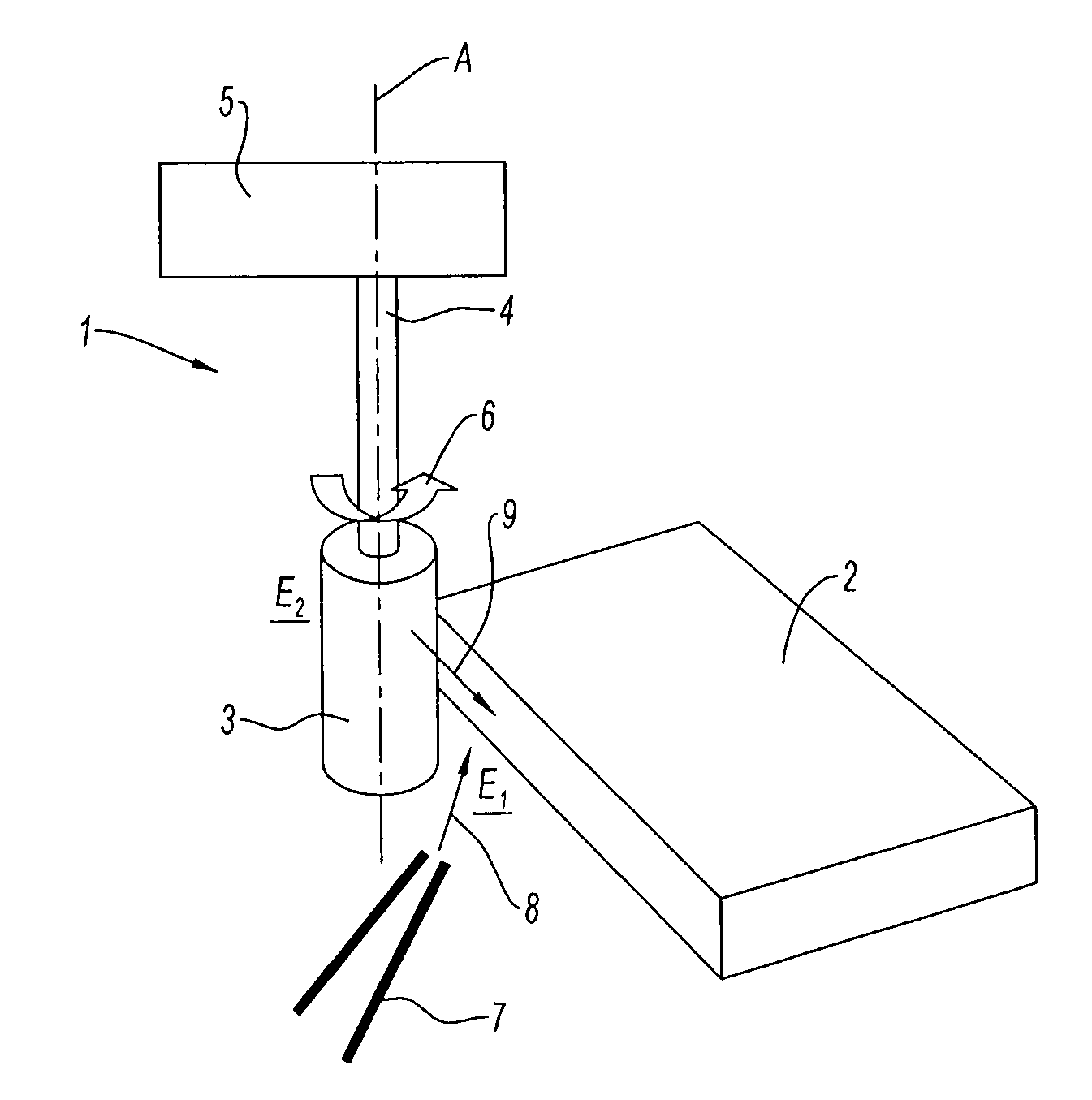

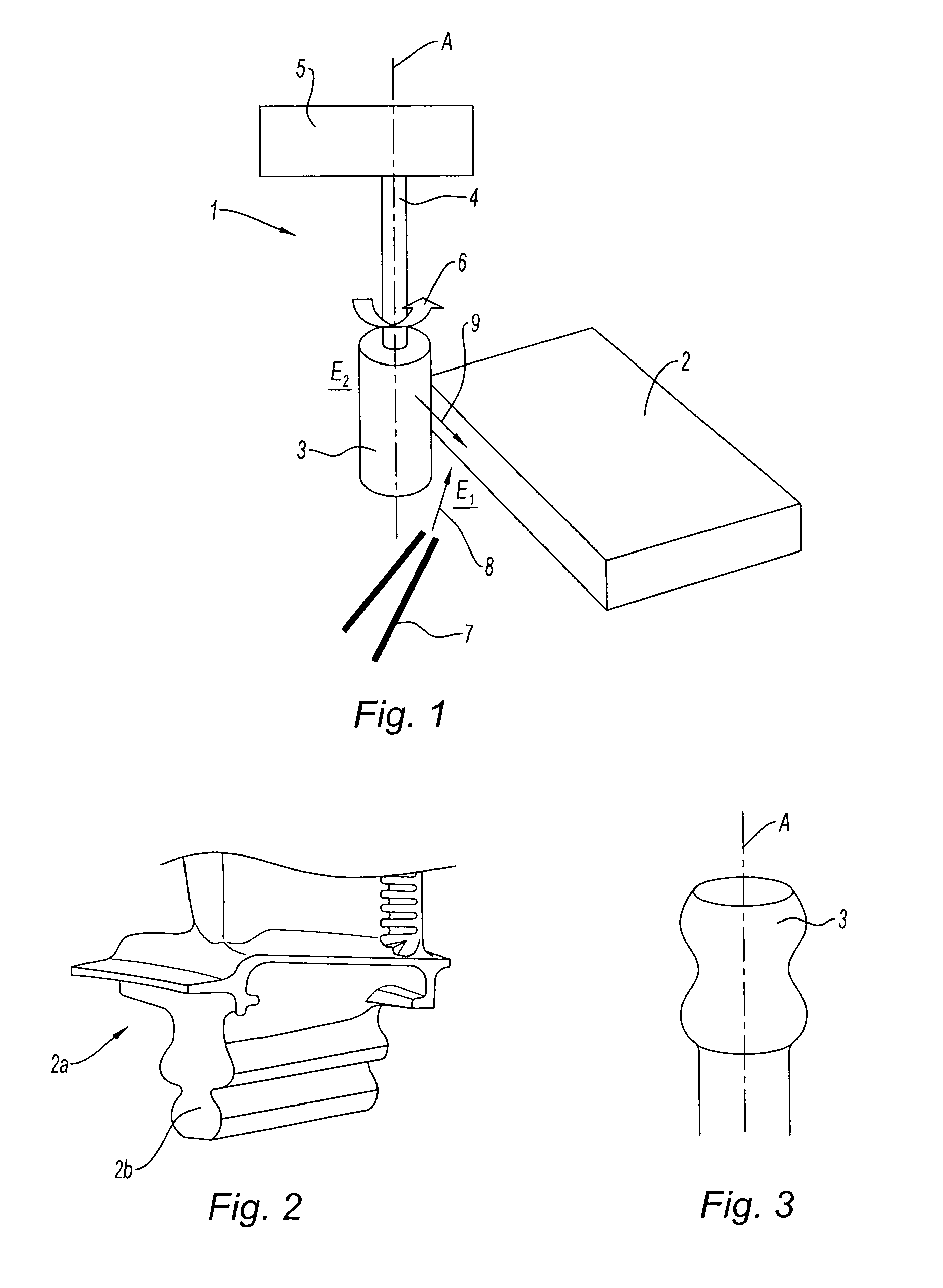

[0023]Referring to FIG. 1, a device 1 for the abrasion machining of a part 2 comprises a pin 3, of axis A, mounted on a shaft 4 that also extends along the axis A and is itself supported by a frame 5. The pin 3 may also be denoted by the expression “rotary head”3. The shaft 4 can be rotated (as represented schematically by the arrow 6 in FIG. 1) by rotary drive means, not shown, comprising here an electric motor, said means being mounted on the frame 5. The shaft 4 then rotates the pin 3 which is integral therewith. The device 1 also includes means (not shown) for positioning and fixing the part 2 relative to the frame 5, in a manner known to those skilled in the art.

[0024]The device also includes all the elements of a center (or device) for conventional machining (motors, position sensors, processing unit, etc.). It is not necessary to describe them in detail because their structure and their function are well known to a person skilled in the art who, to implement the device and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pressure | aaaaa | aaaaa |

| Distance | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com