Heat pump with intgeral solar collector

a solar collector and heat pump technology, applied in the field of heat pump systems, can solve the problems of reducing the efficiency of heat pump, and reducing the requirement for oil lubrication, so as to reduce the density, increase the pressure, and reduce the effect of capital cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

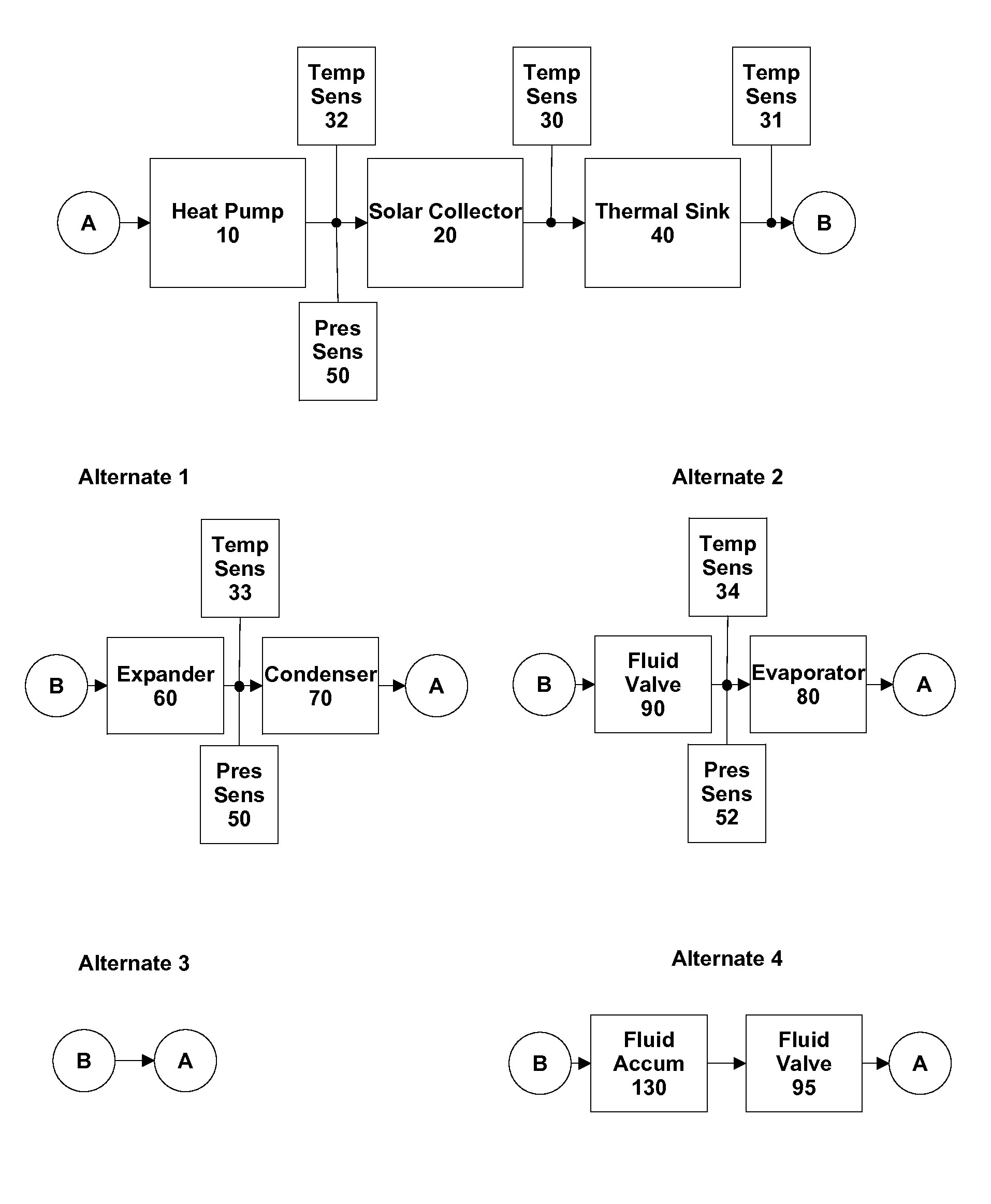

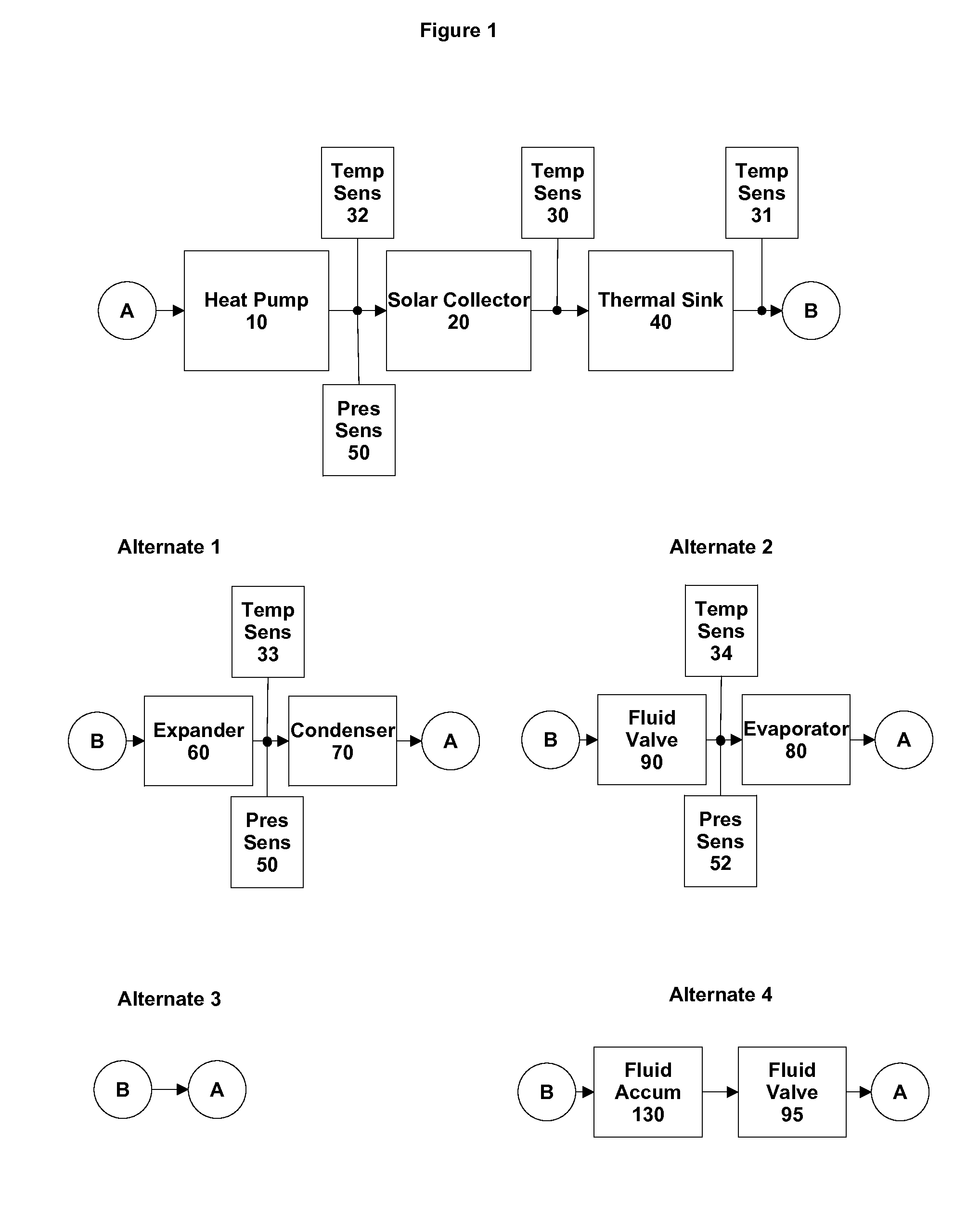

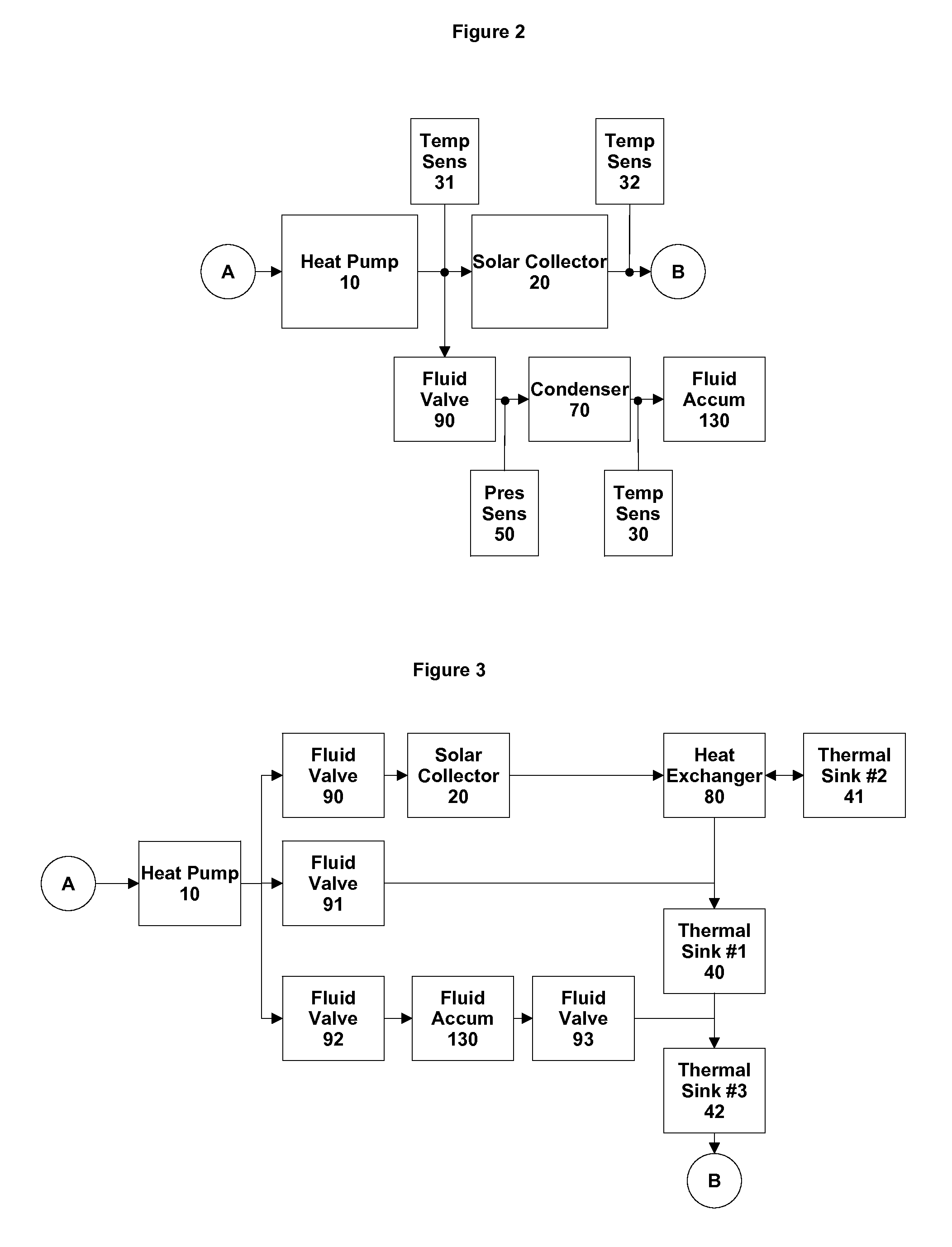

Method used

Image

Examples

Embodiment Construction

[0026]The term “non-linear”, as used herein, includes any surface of a solar receiver whose surface shape is described by a set of nonlinear equations.

[0027]The term “microchannel”, as used herein, includes channel dimensions of less than 2.5 millimeters.

[0028]The term “reflector”, as used herein, includes a surface or surface coating that reflects greater than 50% of at least one portion of the incoming light spectrum, which includes the portions of visible, infrared, and ultraviolet.

[0029]The term “in thermal continuity” or “thermal communication”, as used herein, includes the direct connection between the heat source and the heat sink whether or not a thermal interface material is used.

[0030]The term “multipass”, “multi-pass”, or “multiple passes”, as used herein, includes a fluid flow into at least one portion of a heat exchanger and out of at least one other portion of a heat exchanger wherein the at least one portion of the heat exchanger and the at least one other portion of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com